Digital Image Correlation: How It Changed the Tensile Test

January 30, 2020Comments

For metal formers, one of the simplest and oldest tests is the tensile test. In the simplest form, a tensile test machine must record elongation of the test specimen (Δl) and the reaction force (F) multiple times during the experiment. The recorded data then are used to calculate material properties such as elastic modulus E, also known as Young’s Modulus), yield or proof strength (YS, σY, Rp0.2, or RE); and ultimate tensile strength (UTS, σUTS, Rm). A tensile test also can determine total elongation (TE percent, A percent, A80, A50 and similar), where the numbers indicate the initial gauge length in mm, but its measurement/calculation depends on the test equipment.

|

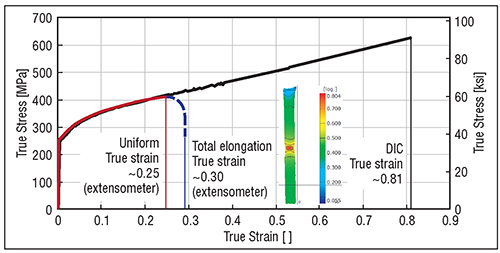

| True Stress-Strain curves of BH220 steel 2 determined with mechanical extensometer and DIC. Image courtesy of At??l??m University Metal Forming Center of Excellence in Ankara, Turkey—The author thanks research engineer Türkay Muratoglu for his support. |

Improvements to tensile test machines started with the introduction of an axial extensometer, a delicate clip-on sensor, with knives on the edges, designed to provide precise measurement of the extension. Instead of relying on crosshead displacement—where frame deflection and slipping of the test specimen can impact accuracy—an extensometer measures elongation of the gauge. Adding an extensometer allowed engineers to precisely measure a material’s elastic modulus and uniform elongation (Ag).

Note: Extensometers are relatively delicate—it is typically advised to remove them before fracture.

By the 1940s, after earing and deep-draw problems had been studied and researchers developed what we now know as r-values (plastic anisotropy coefficients or Lankford parameters), engineers understood that material tests require the simultaneous measurement of length increase and width decrease—achieved by transverse strain measuring. Some extensometers can measure width strain, and, therefore, enable calculation of r-value and Poisson’s ratio.

The 1980s welcomed the introduction of video extensometers for tensile testing. With a tensile specimen marked with a dot pattern, a camera records movement of the dots during the test, and calculates the average length and width strains. This allowed researchers to measure total elongation without user intervention.