The Hazards of Electric Discharge Machines

May 1, 2014Comments

The following hypothetical scenario demonstrates the risks that electronic discharge machines (EDM) can pose:

A fire erupts in a conventional EDM operation, damaging the building and equipment, interrupting business and delaying deliveries to customers. An investigation reveals contributing factors to the fire:

• The part being worked on was not fully submerged in the dielectric fluid.

• The part being worked on was not fully submerged in the dielectric fluid.

• To fit the part in the EDM machine, the operator removed the diffuser from the machine’s fire-extinguishing system, rendering the protection ineffective.

• The machine was operating unattended.

Losses like this point to the need for adequate training of EDM operators with respect to safe procedures for setup and operation; maintaining the integrity of fire-protection systems; and the need to monitor operations.

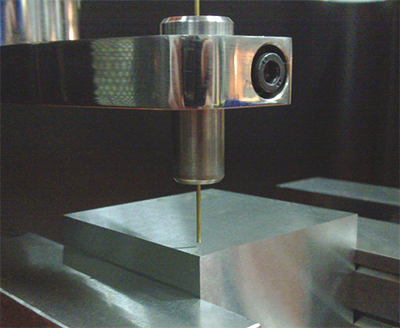

During conventional EDM, the electrode runs in close proximity to the workpiece, bathed in a continuous flow of dielectric fluid. A direct current pulses from the control unit to the electrode, through the dielectric fluid to the workpiece. Each pulse partially ionizes the dielectric fluid and causes a submerged spark. Under normal conditions, a sufficient level of oil above the electrode quenches the spark and prevents ignition of the oil. However, if the oil level becomes too low, the electrode arc can become a ready source of ignition.

The principal hazard associated with this operation is the dielectric fluid, almost als combustible. EDM dielectric fluids generally are silicones (synthetic polymers) or hydrocarbon oils, having a wide range of viscosities and flash points. Ideally the dielectric should not have a flashpoint lower than 250 F or a viscosity lower than 5 centistoke, though flashpoints can be as low as 200F.

Jobs requiring deviations from ideal minimums require special operating procedures and controls to reduce hazards. The temperature of the dielectric should not exceed 100 F during machining. When operating conditions cause the dielectric to heat to temperatures above 100 F, shops should employ an auxiliary cooling system.

Similarly, a wire-EDM operates by sending an electrical charge through a wire into a piece of raw material. The material burns a slowly to create the part.

Both EDM processes can generate flammable gases during machining. The type and quantities of gases produced vary depending on the dielectric fluid, material being machined, and operating temperature, current and voltage.

Proper dielectric fluid level is of utmost importance for safe EDM operations. The fluid level should never drop below a point that would allow gas from the spark region to contact the air. The level should als be high enough to allow gas produced in the discharge region to form a bubble before it breaks to the atmosphere. Equip machines with a switch that triggers and stops the machine if the fluid drops to an unsafe level.

Gases produced during EDM operations can, in some instances, become trapped by the workpiece or in the fluid-handling system (reverse dielectric flow). Prevent this situation by orienting the workpiece, when possible, to eliminate trapped gas. When not possible, provide for a large vent area by mounting the workpiece on blocks with adequate space between blocks.

For fire protection, include automatic systems for machines that run at high amperage or that cut deep cavities. All automatic systems must sound an approved audible warning at least 30 sec. prior to discharge. For machines without automatic protection, shops should keep a CO2 extinguisher (15 lb. min., rated at 12 BC) at each machine.

Give complete instructions to all EDM operators regarding the proper use of fire-protection equipment. Warn operators of the potential for a fire to spread when blowing burning dielectric fluid from the tank with an extinguisher. Extreme care also is necessary to prevent blasting the flame in the direction of anyone assisting with the fire.

Webinar

Webinar