Material Strengths are Increasing, are You Prepared—Part 2

August 1, 2014Comments

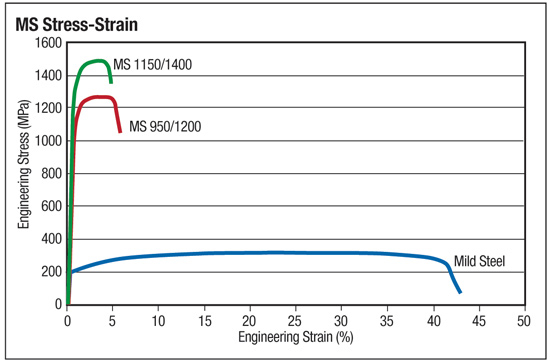

Most activities in the world are constrained by the laws of nature, including metalforming. One must pay some type of price to receive a specific benefit. Last month’s column described how higher material strength generates higher elastic stresses and an increase in springback. Correcting springback to maintain print dimensional specifications becomes more difficult and expensive. Even worse, residual or trapped elastic stresses also can increase and cause reductions in the stability and robustness of stamping dimensions during subsequent processing or in-service operations.

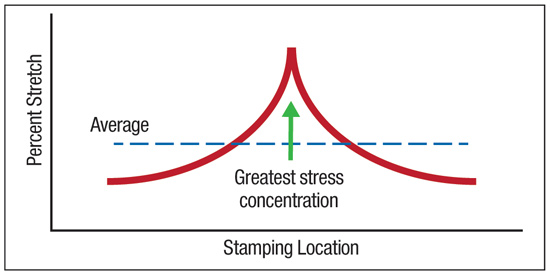

Fig. 1—A stretch gradient grows at a site of concentrated stress. The final height of the gradient is controlled by the workhardening exponent—n-value.

First, consider the formation of a stretch gradient, a narrow localization of high deformation located at a zone of concentrated high stress (Fig. 1). Such locations can be character lines, tight bends, small domes or other severe features in the stamping where deformation begins. If the material did not workharden during deformation, all deformation would concentrate in the gradient as the material thinned. The sheetmetal would quickly reach maximum stretch and tear. With some workhardening (n-value above zero), deformation would cause the material in the gradient to become stronger than the surrounding material, forcing deformation to spread throughout the stamping and reducing the severity of the gradient. A very high n-value could minimize or even prevent a gradient from forming.

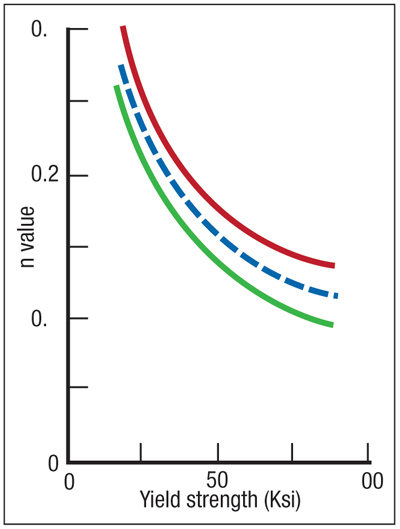

Fig. 3—Workhardening capacity decreases as material yield strength increases. The curve starts with mild steels on the left and transitions to high-strength low-alloy steels on the right.

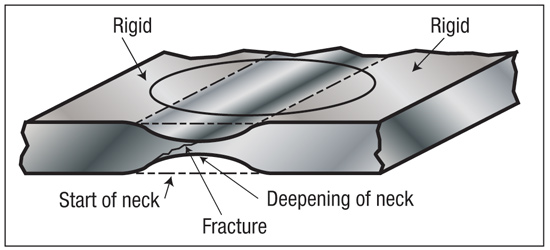

The second example affects the entire stamping as the flat blank is converted by the die into the final shape and dimensions. Various amounts of stretching occur at different locations within the stamping. Finally, a highly stretched area begins to tear. This tear is initiated by a through-thickness neck called a local neck (Fig. 2). We can predict the onset of this local neck using the forming limit curve. Deformation continues in the neck until tearing occurs. A high n-value causes the material at the necking location to workharden more than the rest of the stamping, delaying the onset of failure.

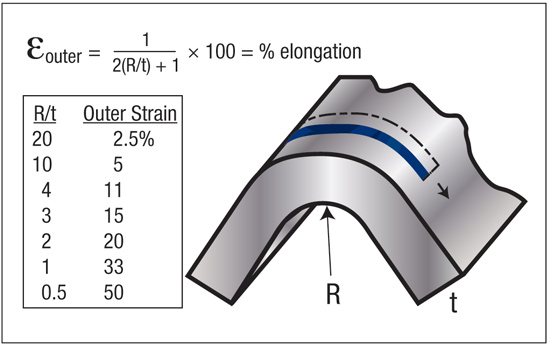

Fig. 4—The strain (stretch) in the outer fiber is a function of bend severity (R/t). Research shows the total elongation relates to the outer strain for a successful bend.

In summary, as the workhardening and n-value increase for a given material yield strength, stretchability increases to allow the forming of more complex stampings.

The real problem occurs when ordering higher strength steels and other metal alloys. Processes at the mills to increase yield strength tend to reduce workhardening capability. Fig. 3 shows this effect for low-carbon steels. Mild (VD-IF and AKDQ) steels usually have yield strengths between 20 and 40 ksi and n-values between 0.27 and 0.18. High-strength low-alloy steels have yield strengths ranging from 35 t0 110 ksi with n-values between 0.20 and 0.10. A reduction in n-value of only 0.02 can cause significant reductions in stretchability in severe stampings.

Other areas of metalforming are affected by increasing the yield strength of the workpiece material. A stronger material requires more energy to form, increasing power costs. This extra energy causes the die and the formed stamping to increase in temperature. The viscosity of the lubricant can decrease, causing galling, scoring and even failure. Different lubricants may be required, dies must be stronger because die impact forces can be greater, and the list of increased problems can grow. MF

View Glossary of Metalforming Terms

Technologies: Materials, Quality Control

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Quality Control

Quality ControlAmrol Jr. New Starrett President and CEO, Other Executives N...

Wednesday, March 5, 2025

Ascential Technologies Appoints Divisional CEO to Specialty ...

Wednesday, April 24, 2024

Materials

MaterialsBrinell, Rockwell and Vickers Hardness Testing: Use and Misu...

Daniel Schaeffler Friday, April 1, 2022

Quality Control

Quality ControlTroubleshooting Sheet Metal Forming Problems, Part 2: The St...

Daniel Schaeffler Friday, February 26, 2021