Wintriss Introduces Advanced Die-Protection Features

February 18, 2021Comments

Wintriss Controls Group, Acton, MA, has introduced 10 new and enhanced die-protection features for the latest version of its SmartPAC Pro press-automation controller, the Advanced DiProPac. "Users will see a familiar programming interface," says Jim Finnerty, product manager, “allowing them to quickly get up to speed on the new Advanced DiProPac.”

Wintriss Controls Group, Acton, MA, has introduced 10 new and enhanced die-protection features for the latest version of its SmartPAC Pro press-automation controller, the Advanced DiProPac. "Users will see a familiar programming interface," says Jim Finnerty, product manager, “allowing them to quickly get up to speed on the new Advanced DiProPac.”Among the new features: a customizable green sensor type called Green Flex. This versatile, cyclic sensor allows for specification of the required state of the sensor at the start and end of the ready window. The sensor can be set to require a specific number of actuations inside the ready window.

A new masking feature available on most Green Sensor types, including Green Flex, is used to monitor events that occur regularly but not on every stroke. For example, applications might include gagging, zig-zag feeds, or where multiple cycles are needed to produce part-feature events that need monitoring on only some cycles.

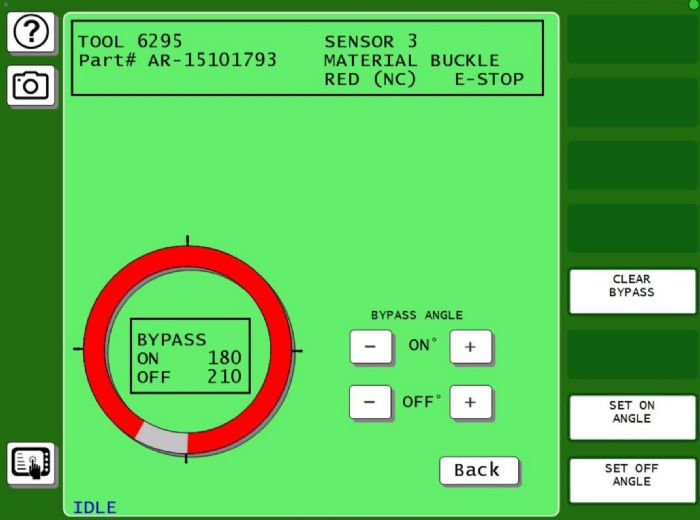

To eliminate nuisance stops caused by the material “jumping” when the die opens, a Bypass Window (see the accompanying photo) can be programmed for static sensors. During the bypass, the sensor will be ignored so that any nuisance fault during that window will not stop the press. Outside of the bypass window, the sensor is monitored normally. To save time and increase efficiency, an auto-reset function has been added to the static sensors so that displayed errors, when removing a finished part, are automatically cleared when the sensor input is appropriately satisfied.

Other Advanced DiProPAC features include improved handling of sensor names; sensor-enable mode is now selectable by tool; and minimum actuation-time setting is added to red and yellow sensors.

See also: Wintriss Controls Group LLC

Technologies: Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationLinear Automation Launches Tonnage-Monitoring System and Cal...

January 3, 2024

New Advanced Features in Wintriss' SmartPac Pro Press-Automa...

November 6, 2023