New from Pilz: Machinery Safety Evaluations

February 14, 2023Comments

Pilz, Canton, MI, has built-out its comprehensive Risk

Assessment/Machinery Safety Audit services with the introduction of Machinery

Safety Evaluations (MSEs), a new service to evaluate the safety of machines.

Metal formers now can obtain a simple, fast overview of the safety and

conformity status of their machines via a dashboard.

Pilz, Canton, MI, has built-out its comprehensive Risk

Assessment/Machinery Safety Audit services with the introduction of Machinery

Safety Evaluations (MSEs), a new service to evaluate the safety of machines.

Metal formers now can obtain a simple, fast overview of the safety and

conformity status of their machines via a dashboard.

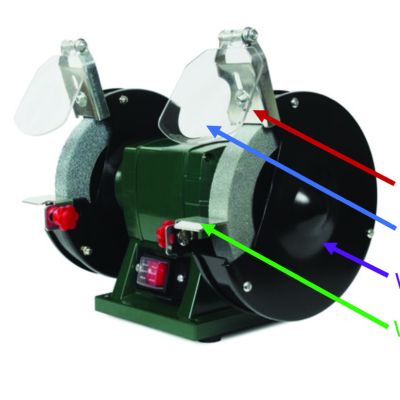

The MSE service comprises an onsite machinery evaluation regarding the applicable safety and conformity requirements. During the process, Pilz not only accounts for the standards and directives applicable at the machine’s place of use or destination, but, on request, also can consider a customer’s individual, inhouse specifications. The result: The current conformity status of each plant or machine can be viewed on a clear, comprehensive software-based dashboard. A list of measures with the appropriate recommended actions—sorted by priority—indicates an efficient route to a safe plant. On request, Pilz also can provide support when implementing these measures.

Pilz developed the MSE service for those who wish to have the safety and conformity of their existing machinery efficiently evaluated, for full staff and liability protection. The service also is appropriate for machines that must be checked for retrofitting, and for new machinery.

The firm offers two levels of detail for an MSE, depending on the requirements:

Webinar

Webinar