Tensile-Bar Shape

Each nation or region has a body responsible for writing standard test procedures, with the American Society for Testing and Materials (ASTM) responsible in the United States. Other organizations include DIN (Germany), JIS (Japan) and ISO (international). From each, we can find the appropriate tensile-bar shape for testing of sheetmetal products. ISO takes the approach of designating Type I, II and III bars, which represent ASTM, DIN and JIS shapes, respectively.

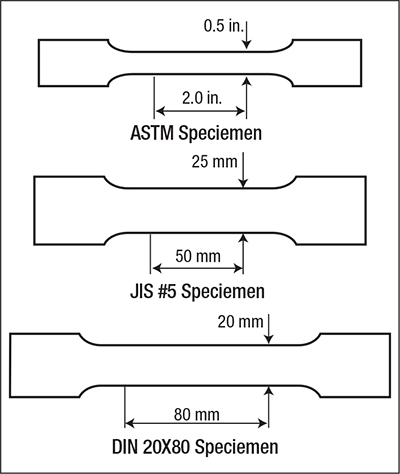

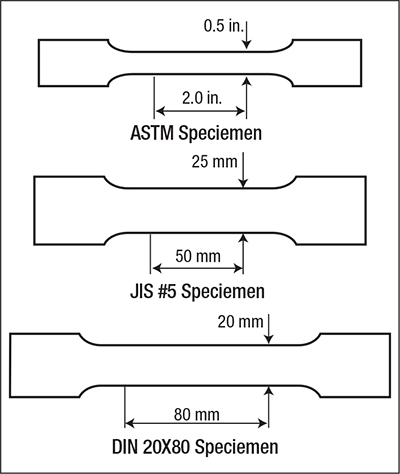

These tensile-bar shapes exhibit significant differences in width and gauge length (Table—Differences in Tensile Bars and Fig. 2). Although the ASTM and JIS bars feature similar gauge length, the width of the JIS bar measures twice that of the ASTM bar. The ASTM and DIN bars feature a 4:1 ratio of gauge length to width, where the JIS bar exhibits a 2:1 ratio.

|

| Fig. 2—Tensile bars, depending on the particular testing standard organization, feature differing widths and gauge lengths. |

These shape differences mean that elongation performance will change depending on the test-sample standard used, even when testing identical material. With the combination of the shortest gauge length and widest sample, elongation from JIS bars typically are higher than what would be generated from the other shapes. Yield strength and tensile strength are not functions of the shape of the tensile bar. The definition of strength: load divided by the cross-sectional area. Even though each of the bars feature a different sample width (and, therefore, a different cross-section), the load is normalized by this value, which negates differences from sample shape.

Why This Matters

There was a time when all test results received from your service center likely came from ASTM tests. In the 1990s, New Domestic automakers, primarily from Japan and Germany, ramped up production within the United States. For a host of reasons, they sourced significant tonnage with U.S.-based steelmakers rather than importing sheetmetal from their home countries.

The requirements for steel grades needed by the New Domestics do not differ significantly than those from the Big Three automakers. What is different: how the sheetmetal should be tested—both the shape of the ASTM/JIS/DIN tensile bar and orientation relative to rolling direction.

Sheetmetal production includes the same constraints as many manufacturing environments, with batch production of the same product as the ideal scenario. A heat of steel may total 300 tons of the same composition, and most steel producers target three heats—roughly 1000 tons—as a minimum production sequence for one composition.

Consider this scenario: If the end customer needs only 800 tons, that leaves several coils that might be sold to service centers. If the primary customer needs JIS bars, then all coils from that sequence will be tested with JIS bars. Any coils making it to service centers likely include a JIS-based certified-metal-property document.

Consider this scenario: If the end customer needs only 800 tons, that leaves several coils that might be sold to service centers. If the primary customer needs JIS bars, then all coils from that sequence will be tested with JIS bars. Any coils making it to service centers likely include a JIS-based certified-metal-property document.

Suppose the certs report 32-percent elongation for a coil, which satisfies the requirement of a minimum 30-percent elongation. A JIS tensile bar will generate a value a few percentage points higher than that generated from an ASTM tensile bar. Combine this with the normal test-to-test variability, and stamping performance may not coincide with your expectations.

Some service centers will provide a copy of the certification document directly from the producing mill. This should indicate the tensile-bar type as well as the test direction listed as L or T, referring to longitudinal or transverse relative to the rolling direction. Other service centers will reprint the test results on their own stationery, but may leave off information about the chosen test bar and test direction. Still others will run their own test, but may or may not include bar type and sample orientation.

When purchasing sheetmetal, check the certified-metal-property document to make sure it has been tested appropriately to your chosen standards. If not, ask your service center to test a sample to your standard-of-choice at an accredited lab. It may save you from an unwanted surprise. MF

See also: Engineering Quality Solutions, Inc., 4M Partners, LLC

Technologies: Quality Control

Consider this scenario: If the end customer needs only 800 tons, that leaves several coils that might be sold to service centers. If the primary customer needs JIS bars, then all coils from that sequence will be tested with JIS bars. Any coils making it to service centers likely include a JIS-based certified-metal-property document.

Consider this scenario: If the end customer needs only 800 tons, that leaves several coils that might be sold to service centers. If the primary customer needs JIS bars, then all coils from that sequence will be tested with JIS bars. Any coils making it to service centers likely include a JIS-based certified-metal-property document.