Threadform Forming Tool Makes Sheetmetal Fastening a Breeze

February 1, 2013Comments

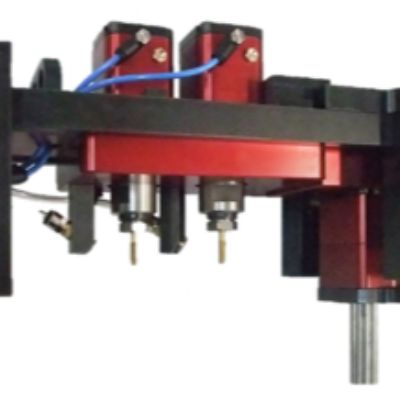

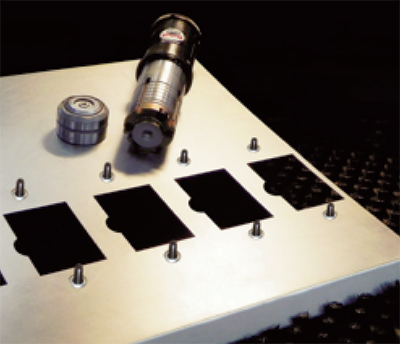

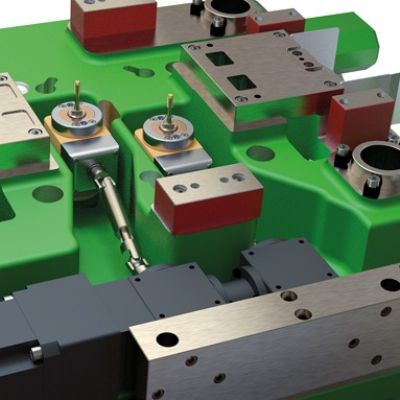

Mate Precision Tooling, Anoka, MN, introduces a new Hybrid Threadform forming tool for punch presses that enables fabricators to fasten two pieces of sheetmetal without tapping or secondary operations. Designed for use when material thickness exceeds screw pitch, the Threadform forming tool thins the material in the center of the form, creating a thread-form helix so that the material fits between the pitch of the screw head in just one operation.

At the heart of this specialized tool is an upper and lower insert machined from high-speed tool steel with a profile that precisely matches the thread helix of the screw thread. Part geometry is modeled electronically using advanced CAD software, creating a three-dimensional solid model for the specific requirements. Users will benefit by eliminating tapping and other labor-intensive secondary operations, such as welding of fasteners. The tool also eliminates debris from tapping and reduces component cost by eliminating the need for special fasteners.

Mate Precision Tooling: 763/421-0230; www.mate.comView Glossary of Metalforming Terms

See also: Mate Precision Tooling

Technologies: In-Die Operations

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. In-Die Operations

In-Die OperationsElectronic Tapping Unit

Wednesday, October 2, 2019

In-Die Operations

In-Die OperationsIn-Die Tapping

Wednesday, October 2, 2019