Punch Press Tooling Ideal for Adding Strengthening Ribs

August 23, 2019Comments

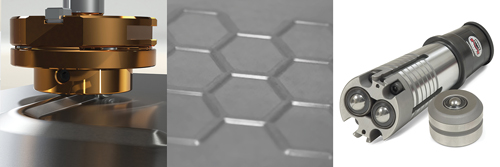

Mate Precision Tooling’s Rollerball punch press tool allows users to quickly and simply create stiffening ribs and decorative beads in sheet metal without secondary operations. The tool forms a rib by pinching the metal between two omnidirectional ball bearings in the upper tool assembly and a single ball bearing in the lower assembly. The shape of the rib is created via the punch press programming system and can be placed anywhere on the part surface.

Mate Precision Tooling’s Rollerball punch press tool allows users to quickly and simply create stiffening ribs and decorative beads in sheet metal without secondary operations. The tool forms a rib by pinching the metal between two omnidirectional ball bearings in the upper tool assembly and a single ball bearing in the lower assembly. The shape of the rib is created via the punch press programming system and can be placed anywhere on the part surface.

“When material is deformed to create the ribs, the material thickness increases, strengthening the material,” explains John Ripka, Mate Precision Tooling application specialist. “The tool allows part designers to reduce sheet metal thickness without compromising the strength and rigidity of the final product. These ribs are essential when using minimum material thickness to control costs. Also, these applications allow fabricators to eliminate secondary operations, resulting in material and labor cost savings with reduced production time.”

Use the Rollerball tool in machines that can hold down the ram while simultaneously moving sheet around the X and or Y axis. When used in machines with accurate stroke control, a simple adjustment to the machines’ stroke length creates a deeper or shorter form. In other thick-turret machines, using the Mate Rollerball in a Mate Ultraform holder offers simplified adjustability by changing the length of the holder with a few clicks of the tool.

Using the Rollerball tool offers a better option than using a standard forming tool to make strengthening ribs, according to company officials, noting that standard forming tools may require tens to hundreds of hits and several minutes to produce strengthening ribs over the length of a sheet. The Rollerball can reduce machine time to a few seconds.

View Glossary of Metalforming Terms

See also: Mate Precision Tooling

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementTariffs are Not a Strategy: A Call for Action by U.S. Manufa...

Laurie Harbour May 27, 2025

Quality Control

Quality ControlPortable Wide-Area CMM

Tuesday, July 8, 2025