• Never stand beneath a load or in the path of a moving load or an AGV.

• Store rigging equipment in a dry, protected environment.

Although basic safety rules are important, proper rigging also benefits from having employees understand the forces involved in moving loads. Motion, gravity and the strength of materials all affect how safely and smoothly a load can be moved.

Calculating LoadsTo select the right rigging equipment for the job, employees must

|

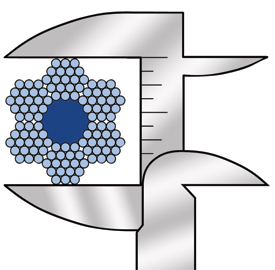

| Over time, stress on wire rope wears a individual wires and elongates the strands. Measure wire rope from the top of one strand to the top of the strand directly opposite it, rather than across two strands side by side. |

know the total load of the object being moved. The weight of a coil, for example, typically is provided by the supplier, but if not, there are tables available that provide the weight per cubic foot for standard materials.

Shop personnel also must locate the load’s center of gravity. For regularly shaped objects, the center of gravity typically is located at the center of the object. However, for irregularly shaped objects like large stamping dies, you may have to make several adjustments before the load is balanced. Any load that tilts more than 5 percent after being lifted off the ground is unbalanced and must be readjusted.

Equipment Inspection

Wire rope finds use for jobs that require extra strength and abrasion resistance. Be sure to measure the rope periodically to ensure its diameter falls within acceptable parameters. Over time, stress on the rope wears a individual wires and elongates the strands. Once the rope falls below the minimum diameter recommended by the manufacturer, it is no longer safe for use.

Measure wire rope from the top of one strand to the top of the strand directly opposite it, rather than across two strands side by side. Rope manufacturers also recommend measuring the rope at three places, at least 5 ft. apart, and using the average of the three measurements.

Rope also can become damaged from repeated dragging over surfaces. A common cause of rope damage is repeated passing of the rope over a drum or through a block. Generally, abrasion resistance depends on the type and hardness of the metal alloy used to construct the rope and the size of the individual outer wires—ropes with larger wires better resist wear than do ropes having smaller wires.

Chains are highly resistant to abrasion and corrosion and find use for applications that would otherwise tend to damage fiber or wire rope.

|

| Chains must be inspected link-by-link prior to any rigging job. Wear typically occurs at the bearing point. If you find a worn link, measure the cross section of the link with a caliper and check its measurement against an unworn area of the link. |

Still, chains must be inspected link-by-link prior to any rigging job. Begin by cleaning the chain with a non-acid, non-caustic solvent so that marks, nicks and other defects become visible. Then lay out the chain on a flat, well-lit surface and examine links for stretching, bending, cracks, wear and rust. Links often become bent or gouged when a chain has been wrapped around an object with sharp edges. Discard any chain that is bent at the weld point.

In a chain link, wear typically occurs at the bearing point. If you find a worn link, measure the cross section of the link with a caliper and check its measurement against an unworn area of the link. If the worn link is less than the minimum allowable thickness, remove the chain from service.

When inspecting chain slings, use the same criteria used to inspect a single chain. In addition, check the sling for proper identification information. The sling should have a tag or other identifier that gives the sling’s size, reach, working-load limit, sling type, and a serial number with the manufacturer’s name or symbol. Do not use slings missing any of this identification information.

Angling for Safe Sling Use

Metalformers must keep an eye on sling angle when using slings to lift loads. Vertical and horizontal forces come into play when lifting objects with a sling, and the amount of force exerted on the sling increases as sling angle decreases. A good rule of thumb: avoid sling angles less than 45 deg. Otherwise, consult with the sling manufacturer on recommended sling angles, inspection criteria and proper use.

The capacity of the sling changes depending on the configuration—choker vs. basket, the number of legs on the sling and the angle of the legs. Basket hitches have higher working-load limits than do choker hitches.

When using a choker hitch, the ideal choke angle is 135 deg.; less than 120 deg. requires a reduction in the load. Never tighten a choker hitch during a lift; instead, pull the choker tight before the load is lifted. MF

View Glossary of Metalforming Terms

See also: Tooling U

Technologies: Coil and Sheet Handling, Safety

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Safety

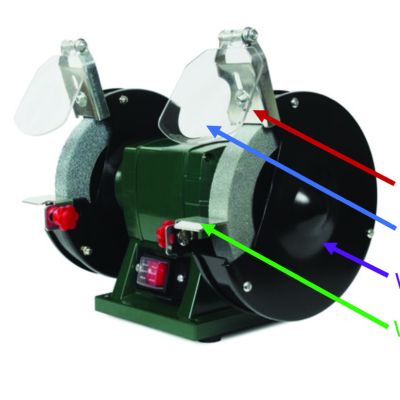

SafetyToolroom Safety

Peter Ulintz Monday, September 25, 2023

Stamping Presses

Stamping PressesMexico Stamping Technology Webinar Series 2023: Day 2

Thursday, March 30, 2023

Webinar

Webinar  Safety

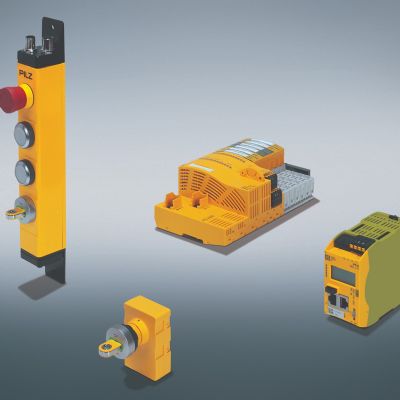

SafetyPilz Digital Maintenance-Safeguarding System an Efficient Al...

Thursday, March 16, 2023