Tackling Tool Wear

June 1, 2018Comments

Automatic Spring Products does this successfully through matching tool and part materials to the application, and working closely with tool-component suppliers.

|

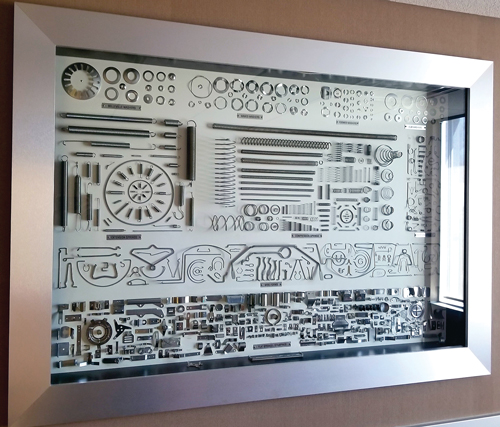

| Automatic Spring Products has devised a tool-rack system to assist in high-volume work for a major automotive OEM. Drawers are organized to hold all manner of tool components, with a component-supplier representative arriving on a biweekly basis to assess component quality and quantity, and present a detailed spreadsheet of inventory. |

“We make things move better.” That succinct description, from Patrick DeShaw, executive vice president of Automatic Spring Products Corp., Grand Haven, MI, accurately sums up the company’s product line. Formed in 1950 and on its third generation of private-family ownership, Automatic Spring Products and its 450 associates in three plants (two in Grand Haven and one in Monterrey, Mexico) ship more than 700 million parts annually. Ninety-five percent go to automotive customers, either OEMs or Tier Ones, for powertrain applications or as interior components for seats, consoles, and door and instrument panels.

The company, humming along on three shifts, five to six days/week, produces custom-designed compression, extension and torsion springs; wire forms; flat springs; stampings; spring and shim washers; and assemblies. To do so, it brings to bear a formidable array of inhouse processes and capabilities, allowing for control of the entire part-creation process from engineering concept and prototyping to tool build and maintenance, manufacturing, heattreating, burr removal, and phosphating.

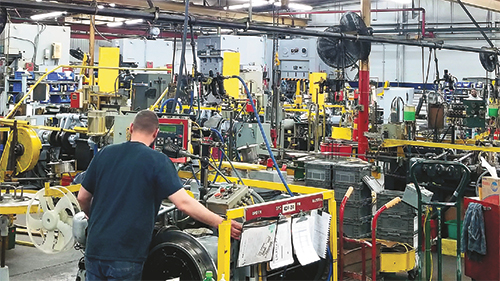

At its 105,000-sq.-ft. main plant in Grand Haven, Automatic Spring Products houses fourslide, tooling, assembly and stamping operations. It was here that MetalForming learned how the company leverages its extensive expertise and experience to best match press tooling to the variety of part materials.

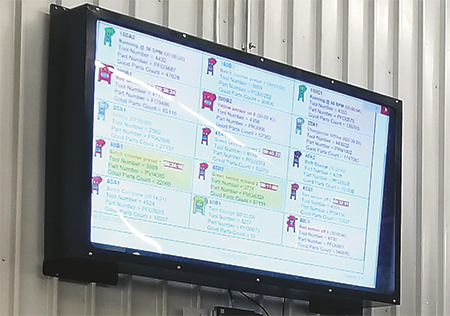

The company’s stable of presses includes mechanical units to 200 tons as well as two new Aida servo-mechanical machines and a new, high-speed Bruderer line. Sensor-laden compound and progressive dies punch and form, with ShopFloorConnect software from Wintriss Controls providing real-time production tracking and OEE for press operations.

Tool Wear at Top of Mind

Though work material runs the gamut, save for advanced high-strength steels, the majority of what Automatic Spring Products stamps is spring steel, some annealed and some hardened.

“Using high-carbon steels, we see excessive wear in our tooling,” explains Rocky Nichols, the company’s tooling systems manager.

|

| At its 105,000-sq.-ft. main plant in Grand Haven, MI, Automatic Spring Products houses fourslide, tooling, assembly and stamping operations. Note fourslide machines in the foreground with recently installed servo-mechanical presses operating at the rear left. |

“The majority of what we stamp here is flat, with some limited forms,” says Nichols, “but to produce good parts in high volumes and meet tight deadlines, we not only must maintain dimensional tolerances, but also edge and surface quality on our tooling. We can’t afford to have punches that wear excessively.”

Excessive and premature tool wear shrinks punch diameters and diminishes surface and edge quality. Automatic Spring Products undertakes a number of measures to address tool wear and maintain strict delivery schedules. An inhouse toolroom boasting a roster of CNC machining equipment stays busy building and servicing dies, and the company is beginning to embark on a robust predictive/preventive-maintenance (PPM) program for all of its tooling. This includes implementing a ShopFloorConnect module that provides such capability. Also, the company is converting spreadsheets of meticulously kept tool-history records to database form in a transition from manual to automated PPM as a scheduling aid.

|

| Real-time production-tracking and OEE software helps keep work flowing, and will assist as Automatic Spring Products embarks on a robust predictive/preventive-maintenance (PPM) program for all of its tooling. The company is converting spreadsheets of meticulously kept tool-history records to database form in a transition from manual to automated PPM as a scheduling aid. |

Identifying outside sources for effective tooling components represents another measure. Here, a relationship with Wilson Tool International, White Bear Lake, MN, pays big dividends. Automatic Spring Products employs Wilson Tool’s Impax Tooling Solutions punches as well as coating services, especially for use in circular-tool applications for compound dies, explains Fred Beamer, master toolmaker at Automatic Spring Products. The company uses Wilson Tool’s HP Accu-Lock retainer inserts to manufacture custom retainers inhouse, which enable quick returns to production without waiting for shipment of custom retainers.

Keeps Component Supply at the Ready

As important as longer tool life is to Automatic Spring Products, keeping components stocked and at the ready is just as vital. For example, high-volume work for a major automotive OEM must stay on schedule, and parts must maintain quality through runs that last into the millions. To keep on track, Automatic Spring Products has devised a rack system, with drawers organized to hold all manner of tool components. A Wilson Tool representative arrives on a biweekly basis to meticulously assess component quality and quantity, and present detailed inventory spreadsheet.

“We receive a spreadsheet of what is low and what replacements will arrive,” Nichols says. “We can see what continuously comes up low in inventory, and then bump up the quantity of that component stored in the drawer.”

Automatic Spring Products has added Wilson Tool components directly into the company’s standards. Should a component be outsourced, it must be sourced directly or be Wilson Tool-compatible. Quick turnaround on replacements is another relationship plus, notes Nichols. Combining that with the frequent visits to assess inventory paints a picture of ideal customer service. Other customer-service plusses noted by Automatic Spring Products include networking with local coaters to further reduce lead time on tool-coating work, and providing expertise on engineering challenges.

“With our Wilson Tool representatives we’ve discussed issues encountered when running problematic materials, and we’ve received very helpful suggestions,” says Beamer.

Facing high volumes and extremely tight deadlines, Automatic Spring Products appreciates the helpful hands of long-time partners such as Wilson Tool in staying on top among its competition. Premium-freight charges paid to shippers to expedite delivery in efforts to meet customer deadlines, and also an on-time-shipment measurable—often can enter the discussion in such environments, and these charges can be avoided if all partners are on the same page.

“We can’t afford downtime or sacrificed quality,” says Nichols. “Our customers, internal and external, demand on-time delivery and parts made to their specifications. We must get our quality product where it needs to go as quickly as possible.” MF

View Glossary of Metalforming Terms

See also: Impax Tooling Solutions, A Div. of Wilson Tool International

Technologies: Tooling