Slug Pulling a Problem of the Past

May 2, 2025Comments

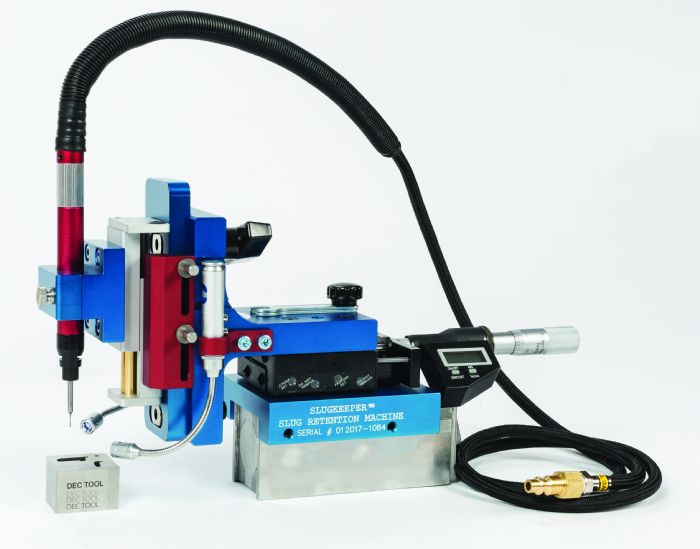

…for Superb Industries, an Ohio metal former that employs a special tool to improve slug retention across a range of jobs and processes.

Ninety miles south of Cleveland, the small town of Sugarcreek, OH, is quite the find. Nestled in Ohio’s Amish Country, ‘The Little Switzerland of Ohio’ boasts what once was the world’s largest cuckoo clock—featured on the 1977 cover of the Guinness Book of World Records—and exudes an Old World rural charm. Tourists flock to this hamlet as a reminder of less hectic and slower-moving times.

Hard to believe that Sugarcreek boasts leading-edge manufacturing technology and capabilities, but it certainly does. One stellar example: Superb Industries, founded by brothers Dan and John Miller in 1986. The Millers trace their lineage 10 generations back to the Mueller artisan-farmer clan that arrived on American shores in 1749, and the brothers infused that family experience into their burgeoning business. Success followed, and by 2000, Superb Industries outgrew its small garage, eventually expanding to its current 70,000-sq.-ft. facility in Sugarcreek.

Hard to believe that Sugarcreek boasts leading-edge manufacturing technology and capabilities, but it certainly does. One stellar example: Superb Industries, founded by brothers Dan and John Miller in 1986. The Millers trace their lineage 10 generations back to the Mueller artisan-farmer clan that arrived on American shores in 1749, and the brothers infused that family experience into their burgeoning business. Success followed, and by 2000, Superb Industries outgrew its small garage, eventually expanding to its current 70,000-sq.-ft. facility in Sugarcreek.

With an organizational chart illustrated as a majestic shade tree—a management trunk supports the branches of people and processes that yield the ‘fruit’ of parts and components. The company incorporates the traditional values of its family owners while investing in technologies and automation that rival that of the most sophisticated manufacturers on earth.

Superb Industries’ 70 employees produced to the tune of about $35 million in revenue for 2024—growing annually at a double-digit clip since 2019. And, the company has the distinction of being named by Inc. as among the top 100 fastest-growing privately held U.S. manufacturers. Markets for Superb Industries parts, components and assemblies—almost 1.4 billion parts shipped annually—include 35% automotive followed by a smaller percentage to appliance, and the rest split between security, construction, electronics and others. With so much going out the door, the manufacturer—holding ISO 9001 and IATF 16949 certifications—still boasts an on-time-delivery rate surpassing 98%.

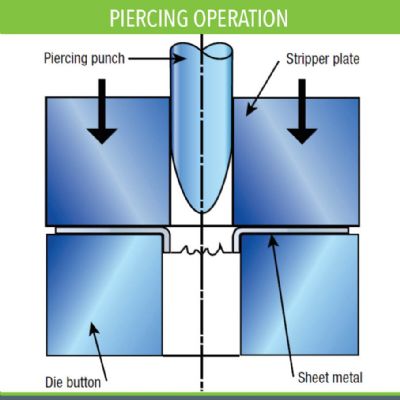

Sophisticated Operations Test Slug Retention

To produce quality parts in such high volumes, Superb Industries relies on a stable of Bihler automated forming machines and Bruderer stamping presses, in addition to injection molding machines. The stamping presses range in capacities from 30 to 120 tons, and the Bihler lineup includes GRM80 and GL3000 manufacturing cells as well as Bimeric 1500 and 3000 servo-driven cells.

With impressive inhouse automation and integration expertise, the company often combines Bihler and Bruderer equipment in cells to produce unique electrical components. These include terminals and connectors of brass, copper and precious metal alloys, packaged in bulk, reel-to-reel or stacked for automated assembly.

“This precision machinery, and our ability to tie it together along with our specialized tooling, allows us to maintain consistency in production via what we call hybrid, high-speed stamping,” Susan Miller, Superb Industries human resources manager, says.

Webinar

Webinar