History of the Progressive Die

April 1, 2012Comments

Prior to the discovery of metals, people used simple hand tools made from bone, rock and wood. Following the discovery of fire, humans learned that adding heat to certain rocks (ores) would free the metal from the rock. Eventually, the art of extracting and smelting metals and forming them into usable objects evolved—commonly referred to as metalworking.

Metalworkers were valuable members of early societies. As more and more products and tools began to be made from metals, society needed more people skilled in the craft of metalworking. Objects made from metals were necessary for industry, farming, jewelry-making and defense purposes.

Old coins reveal that the art of die sinking—a process that creates a cavity, or opening, of a specific size and shape for casting or forging—was known to the ancient Greeks at least back to 800 B.C. (ref: J.L Lewis, Dies and Die Making, Journal of Commerce, 1897). However, these artifacts do not show that the use of punches and dies was equally known.

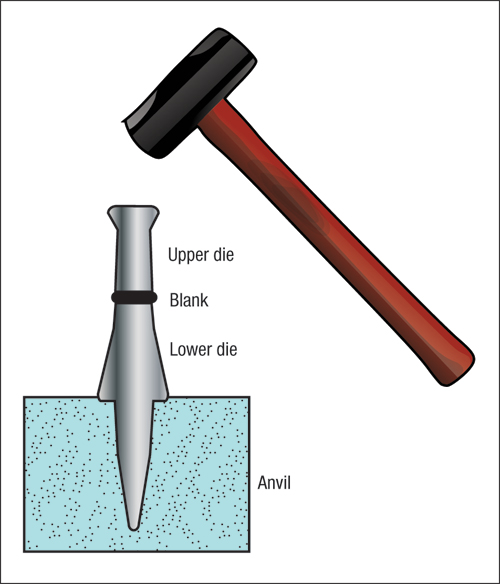

Eventually, coins were struck using two coining dies: a lower die depicting the coin in a negative form and a companion upper die. A metalworker placed a blank between these two dies and the upper die was struck with a heavy hammer, rendering a positive image on the blank (Fig. 1). The hammer method was used well into the Middle Ages. Even today people occasionally speak of coins being “struck.”

The first record of punches and dies being used in a machine having guides (or s) to ensure punch-die alignment appears in the 15th century, when a German locksmith used the process to manufacture hinges. In 1796, a Frenchman named DeVere earned a patent for “Dies for Punching and Drawing Sheet Metal,” perhaps the first of its kind.

The first record of punches and dies being used in a machine having guides (or s) to ensure punch-die alignment appears in the 15th century, when a German locksmith used the process to manufacture hinges. In 1796, a Frenchman named DeVere earned a patent for “Dies for Punching and Drawing Sheet Metal,” perhaps the first of its kind.

A significant advancement in metal-stamping operations came with the development of the progressive stamping die. A book by Oberlin Smith titled, The Press Working of Metals (Wiley and Sons, 1896), describes “follow-on” tooling and “successive gang cutting” in a manner that suggests that they may be early predecessors of the progressive die. The 1897 book by J.L. Lewis contains the earliest published record I could find to a progressive die.

The use of progressive dies during the first half of the 20th century was limited primarily to companies producing their own products in very high quantity—electric-motor components, for example. The first edition of the Die Design Handbook (American Society of Tool and Manufacturing, 1955) contains an entire chapter on progressive dies, and offers numerous examples and illustrations of progressive-die designs and die strips for such parts.

After World War II, the U.S. economy surged. Most contract manufacturers of the time produced metal stampings in single-operation dies and presses. Operators hand-fed strip material into presses equipped with blanking dies. Blanks dropped into containers that were then delivered to subsequent hand-fed press-and-die forming and cutting operations.