Schuler Improves Automatic-Transmission Die Technology

August 1, 2012Comments

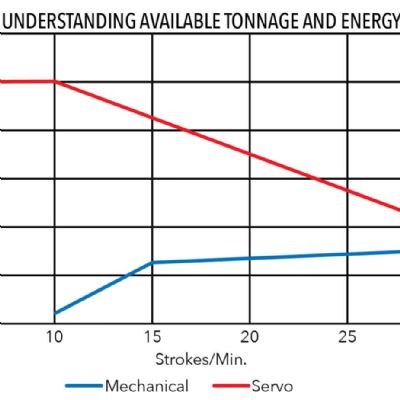

Schuler Inc., Canton, MI, announced several new approaches it has developed for stamping transmission components using advanced in-die processes such as spline forming with in-die rollers; rollforming with smaller in-die rollers; and segment forming for stamping tall, thin components.

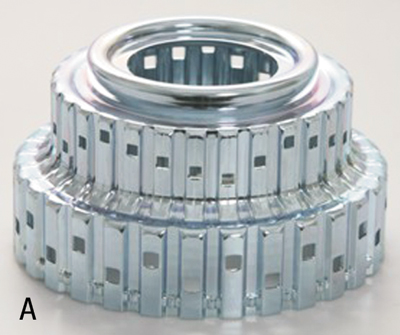

“The market demand for clutch packs made from high-strength disc carriers (photo A) with consistent tolerances and economic production methods continues to grow,” says Dr. Lars Gerlach, sales director, Schuler Cartec.

The firm’s spline-forming process using in-die rollers can achieve consistent dimensional accuracy for wall thickness, piston pockets and major and minor diameters, say company officials. The one-step process reportedly reduces part stress and minimizes material thin-out from end-to-end of the spline, while improving surface hardness by 25 to 30 percent with run-out tolerances of ±0.15 mm.

The patented smaller in-die roller process is designed for components that require high centrifugal forces. The proprietary process minimizes process time because it can draw and roll in one die using smaller rollers and a special bearing design. By combining the draw and roll stations, the process allows parts to be formed in fewer stations, reducing die size and cost.

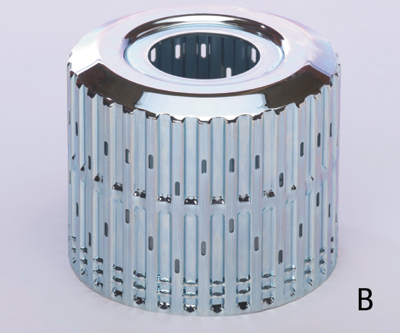

Lastly, Schuler’s patented segment-forming process allows spline-rolling of tall components from relatively thin sheet, without material thinning. In this process, parts can be rolled over the full length, allowing for reinforcement rings in the middle and tapered lead-ins to ease clutch-plate assembly (photo B).

Schuler Inc.: 734/207-7200; www.schulerinc.comView Glossary of Metalforming Terms

See also: Andritz Schuler

Technologies: Stamping Presses, Tooling