High-Speed Mechanical Stamping Press

September 3, 2024Comments

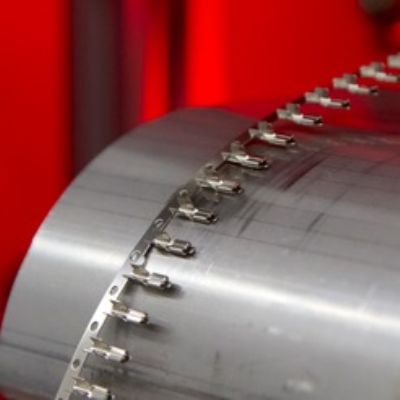

TechXpo, held earlier this year at Bruderer Machinery Inc., Ridgefield, NJ, showcased the press builder’s—and its partners’—recent advancements in high-speed stamping presses and peripheral equipment. The event included display of Bruderer’s BSTL 350-88 energy-efficient, high-speed mechanical stamping press, new to North America and featuring innovative drive and control-system technology as well as friction-reducing measures.

TechXpo, held earlier this year at Bruderer Machinery Inc., Ridgefield, NJ, showcased the press builder’s—and its partners’—recent advancements in high-speed stamping presses and peripheral equipment. The event included display of Bruderer’s BSTL 350-88 energy-efficient, high-speed mechanical stamping press, new to North America and featuring innovative drive and control-system technology as well as friction-reducing measures.

The 350-kN press offers a bed of 870 by 536 mm and operates at speeds from 100 to 1200 strokes/min. with four fixed stroke-length options: 15.9, 19, 25.4 and 31.8 mm. Its industrial-computer-based control enables optimum integration of all machine functions as well as technology and monitoring functions specific to the stamping process. A universal interface—OPC UA protocol—allows for connection to all common peripheral devices and higher-level systems.

A unique drive-lever system, according to company officials, allows the load acting on the ram to be distributed across the system. This load distribution, together with minimum-clearance engineering and an efficient lubrication system, they offer, are crucial factors in enabling high press durability and consistent precision when forming.

Together, two stamping-press production lines were running at TechXpo with a third on display, as well as various peripheral equipment from Bruderer and partner companies.

See also: Bruderer Machinery, Inc.

Technologies: Stamping Presses