“Modern sheet-hydroforming machines,” Dixon continues, “do not rely on displacement pressure; they can generate the needed pressure at any given draw height regardless of punch size. One machine, therefore, can cover a broad range of punch and part sizes.”

Not Just for Hydroforming Shops

Dixon finds that while hydroforming companies certainly can leverage the advantages provided by new state-of-the-art machines, metal forming job shops that perform deep drawing operations also find use for the technology. “This is particularly true for shops performing low-volume high-mix production … anything under 60,000 parts/yr.,” he says. “The tooling costs for sheet hydroforming—because one of the tools is a pressurized rubber diaphragm that serves as a universal female die—are low, typically 70 to 90% less expensive than a mated die set for use in a deep-draw stamping press.”

Dixon finds that while hydroforming companies certainly can leverage the advantages provided by new state-of-the-art machines, metal forming job shops that perform deep drawing operations also find use for the technology. “This is particularly true for shops performing low-volume high-mix production … anything under 60,000 parts/yr.,” he says. “The tooling costs for sheet hydroforming—because one of the tools is a pressurized rubber diaphragm that serves as a universal female die—are low, typically 70 to 90% less expensive than a mated die set for use in a deep-draw stamping press.”

The McGeevers note other advantages realized since replacing their old machine with new. “We’re often able to accomplish deeper draws, to 6 or 7 in., in one pass,” explains John Ryan. “On 50 to 60% of the parts drawn on the older machines, we would need to develop a three- or four-step forming process and anneal the parts between each draw, to stress-relieve and alleviate the work hardening.”

He offers up one example: a job the firm has been running for 30-plus yr. forming ⅛-in.-thick Inconel 625 for a military application. “The customer regularly orders 1000-part production runs,” explains John F. McGeever. “We used to have to draw the parts half-way, then anneal them before completing the draw. Now we draw these parts in one pass.”

He then offers a tremendous productivity bonus with the new machine: reengineering a one-out draw-forming die to three-out, effectively tripling productivity.

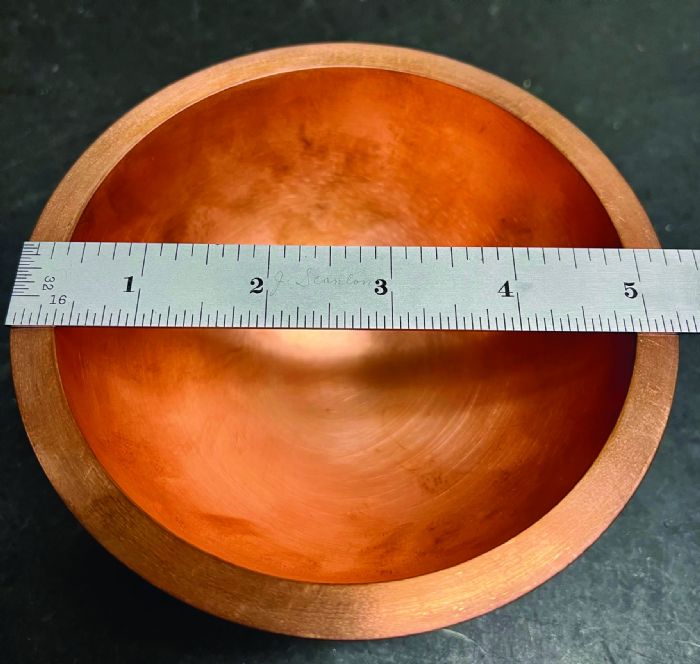

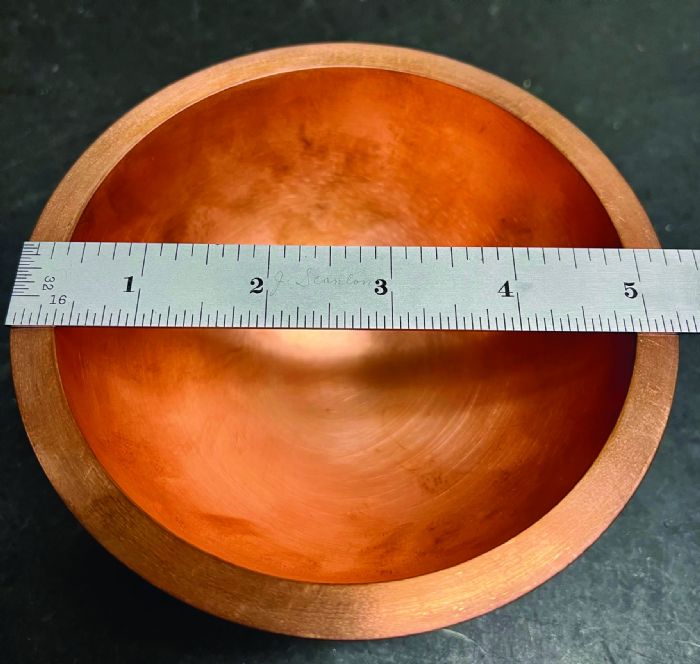

“We’ve been running this part for years,” explains John F. McGeever, describing the part as a 3.5-in.-dia. pressure-vessel head drawn from 18-gauge stainless steel. “With the pressure-generating capability of the new hydroforming machine, we’re able to build enough pressure across the entire bladder to simultaneously drive three punches, drawing three parts per cycle.”

Yet one more advantage, as shared by the younger McGeever: The new 10,000-psi machine actually can form parts that the firm typically would run through its other hydroforming press in its shop, a 15,000-psi model. How can this be? Again, it comes back to no longer using displacement pressure to generate forming pressure. Dixon again explains:

“Due to the use of displacement pressure in the older machines, the required pressure is more of a suggestion. On specific parts that require higher pressure early on in the draw, older machines using displacement pressure may not perform well. Having the ability to generate the exact pressure at the exact point needed in the draw allows these newer machines to form parts at lower pressures.”

“Due to the use of displacement pressure in the older machines, the required pressure is more of a suggestion. On specific parts that require higher pressure early on in the draw, older machines using displacement pressure may not perform well. Having the ability to generate the exact pressure at the exact point needed in the draw allows these newer machines to form parts at lower pressures.”

More Science, Less Art

Newer, more precise press controls also deliver benefits, say the McGeevers, “making deep drawing more of a science and less of an art,” John Ryan notes. “We can control as many as 30 different steps in the process, precisely setting pressure and punch position. We even can open the press (with the Triform In-Sight feature) during process development to observe how the material is flowing, and make any necessary adjustments, which proves very helpful during prototyping. This ability reduces the amount of scrap from a development standpoint. Then we can save the final process recipe and store it for later use in production.”

John Ryan notes that with the precise CNC machine control, development of new part programs takes minutes, not hours. “On the old machine,” he explains, “it could take us 15 to 20 parts during process development to dial-in a program. Now, we often get the process dialed in on the first or second part. For example, we have a repeat job we run for an aerospace customer, forming Hastelloy X—not an inexpensive material. To dial in the process on the old machine, we’d run 15 to 20 test parts from stainless steel before loading any of the Hastelloy into the hydroforming machine, to reduce our scrap costs. Now, with a good, repeatable process developed and stored in the Triform machine control, we form good first parts off of the machine and have eliminated all of the setup time and scrap.”

This new-found confidence in the accuracy and repeatability of its sheet-hydroforming capabilities has Charles Schillinger taking on projects it might have no-quoted previously. Example: A customer in California recently approached the McGeevers looking to form 5-in.-dia. hemispherical parts from ⅜-in.-thick copper. “Knowing the capabilities of the Triform, not only did we quote the job, but we landed it,” John Ryan shares.

Another example: “We recently quoted a vessel head from ¼-in.-thick stainless, which we would have no-quoted before,” he says. “We quoted it and are confident that we’ll land it.”

The Benefits of Laser Blanking

The McGeevers point out one additional productivity enhancer they’ve recently brought on board:

“In 2021 we invested in a fiber-laser cutting machine (a 4-kW Bystronic model) and it’s dramatically changed our business,” explains John Ryan. “We lean on the machine for producing nested blanks from 5 by 10-ft. sheets, to support our hydroforming operations as well as our spinning department. We also use it in our sheet metal fabrication department, bringing back inhouse the cutting work we used to outsource.

“Laser blanking in place of using a circle shear,” he concludes, “has taken us from not being able to get blanks to the forming machine on time to now having stacks of blanks in front of each machine when it comes time to start production. We’re pushing significantly more volume through the shop. It’s been extraordinary for us.” MF

Industry-Related Terms: Blanking,

Circle,

CNC (Computer Numerical Control),

Die,

Draw,

Drawing,

Form,

Forming,

LASER,

Model,

Run,

Scrap,

Stainless SteelView Glossary of Metalforming Terms

See also: Beckwood Press Company, Bystronic Inc.

Technologies: Stamping Presses, Tooling

Charles Schillinger Co., a 95+-yr.-old metal-spinning and deep-draw metal former that also provides metal stamping, CNC machining and welding, hydroforms shapes to 12-in. dia., drawn to a maximum depth of 7 in.

Charles Schillinger Co., a 95+-yr.-old metal-spinning and deep-draw metal former that also provides metal stamping, CNC machining and welding, hydroforms shapes to 12-in. dia., drawn to a maximum depth of 7 in.

Dixon finds that while hydroforming companies certainly can leverage the advantages provided by new state-of-the-art machines, metal forming job shops that perform deep drawing operations also find use for the technology. “This is particularly true for shops performing low-volume high-mix production … anything under 60,000 parts/yr.,” he says. “The tooling costs for sheet hydroforming—because one of the tools is a pressurized rubber diaphragm that serves as a universal female die—are low, typically 70 to 90% less expensive than a mated die set for use in a deep-draw stamping press.”

Dixon finds that while hydroforming companies certainly can leverage the advantages provided by new state-of-the-art machines, metal forming job shops that perform deep drawing operations also find use for the technology. “This is particularly true for shops performing low-volume high-mix production … anything under 60,000 parts/yr.,” he says. “The tooling costs for sheet hydroforming—because one of the tools is a pressurized rubber diaphragm that serves as a universal female die—are low, typically 70 to 90% less expensive than a mated die set for use in a deep-draw stamping press.” “Due to the use of displacement pressure in the older machines, the required pressure is more of a suggestion. On specific parts that require higher pressure early on in the draw, older machines using displacement pressure may not perform well. Having the ability to generate the exact pressure at the exact point needed in the draw allows these newer machines to form parts at lower pressures.”

“Due to the use of displacement pressure in the older machines, the required pressure is more of a suggestion. On specific parts that require higher pressure early on in the draw, older machines using displacement pressure may not perform well. Having the ability to generate the exact pressure at the exact point needed in the draw allows these newer machines to form parts at lower pressures.”

Video

Video