Stamper Overcomes Slug-Pulling Hurdles

March 1, 2013Comments

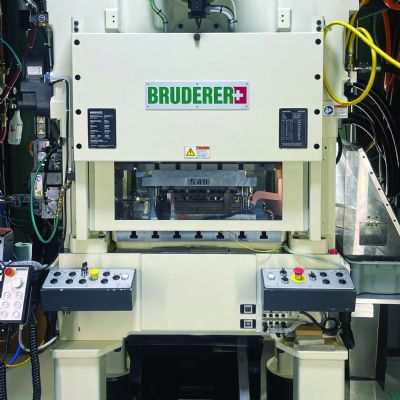

Early in 2012, Bloomingdale, IL-based Bi-Link, a provider of stamped metal and injection-molded parts, finally found the slug-pulling solution it was looking for—a Slug Keeper slug-retention machine developed by DTC Products, a division of Dec Tool Corp., St. Charles, IL. Bi-Link toolroom supervisor Scott Bedow had grown tired of watching as slugs pulled back onto die blocks during stamping. This pesky problem caused unplanned downtime and associated costs as presses stopped so operators could remove slugs and inspect parts and dies for damage. Now, Bedow reports that the slug-retention machine has virtually eliminated slug-pulling events.

The slug-retention machine uses a pneumatically powered grinder to precisely machine a small angled groove into the sidewall of a stamping-die cavity. A micrometer coupled to the drive of the machine’s slide enables precise movement of the machine’s carriage to control the depth of the slug-retention groove. The groove creates a precise amount of interference so that during stamping, the slugs expand into these grooves to prevent them from being pulled back up to the top of the die block and onto the die surface.

Bi-Link primarily employs the machine when stamping thicker stainless-steel medical components as well as automotive parts of high-strength low-alloy steel. Run at high volumes, dies to stamp these parts typically feature full-carbide inserts and punches, expensive to manufacture and therefore worthy of protection from the damage that pulled slugs can cause.

The slug-retention machine measures less than 10 in. high, and features a magnetic base so it can mount temporarily but firmly in place on the die surface during the grooving operation. “The nice feature with the machine is that we don’t have to tear each die apart and set up one block at a time in the machine,” says Bedow. “Instead, we just move it down the line in the die.”

DTC Products, a division of Dec Tool Corp.: 866/682-3602; www.dectool.com

See also: Dec Tool Corporation

Technologies: Stamping Presses