From Theory to Practice

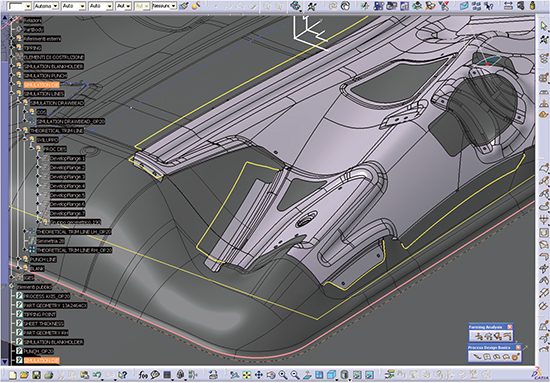

To assess the operating potential and adaptability of its new software, Fontana engineers carried out thorough tests on a designated project of one production line. At the same time, two additional projects were carried out implementing the strategies currently in use.

“Each of the three projects,” says Cavenago, “went through the same work phases. In the end we noticed that when applying the features of AutoForm-ProcessDesignerforCatia, the designated project clearly showed relevant time savings.”

One benefit not to be underestimated: When compared with a Catia license, this software can be used during the running session by adding the AutoForm-ProcessDesignerforCatia license, every time it is required. At the same time, the software allows for a high quality level of data update.

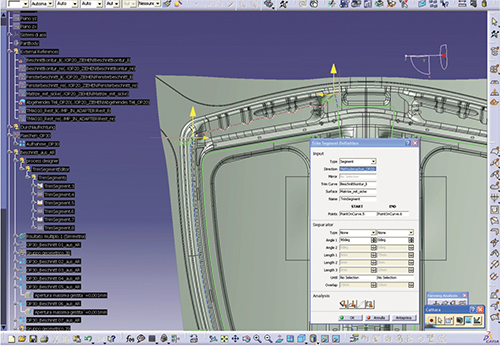

“Our objective,” continues Cavenago, “is to use AutoForm-ProcessDesignerforCatia with any of our customers’ files. We hope to create an even closer connection between AutoForm-DieDesignerplus and AutoForm-ProcessDesignerforCatia in order to reproduce the parameters already defined during simulation on surfaces or draw beads.”

The Added Value of Quality

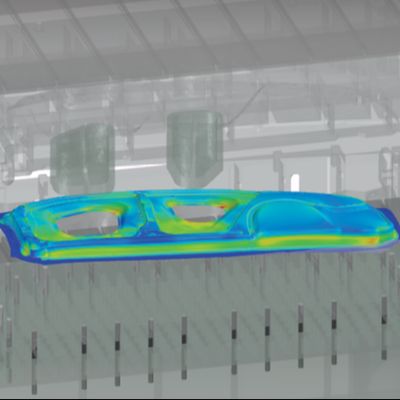

Fontana Pietro now has found ways to extend the use of its new software to other departments within the company, such as in die-process engineering. Here, the die-process engineer’s job during early product development is eased thanks to the validity and speed of analysis. This is due to the reuse and reproducibility of data, the efficient exchange of data (internally among departments and externally among OEMs and their suppliers) and the quick creation of die layouts that include drawing as well as all secondary operations.

The various sketches and construction elements used in Catia V5 are assembled in few yet powerful features that allow for easy and rapid surface design. A comprehensible data structure simplifies the use of these new features and improves collaboration internally. The high-quality surfaces created in the software are characterized by a significantly reduced number of control elements and the appropriate surface continuity, say Fontana engineers. These surfaces can immediately be used for further operations, such as over-crowning and CNC machining.

“Over-crowning,” concludes Fontana R & D engineer Guglielmo Oleari, “will be the object of further and future operating strategies within our company. We will generate rules to further reduce the time needed to develop surfaces.” MF

Article provided by AutoForm Engineering; www.autoform.com.View Glossary of Metalforming Terms

See also: Autoform Engineering USA

Webinar

Webinar