Springback Prediction Yields Automotive Parts Without Costly Tool Recuts

June 24, 2019Comments

Family-owned Atlas Tool Inc., Roseville, MI, provides tool building and low-volume stamping with its impressive stable of 40 mechanical and hydraulic presses. Through the use of advanced simulation software from AutoForm, the company’s engineers were able to accurately predict springback when stamping an automotive rear cab reinforcement part from 1.3-mm-thick DP600 advanced high-strength steel (AHSS), saving significant time and money as compared to a trial-and-error approach.

|

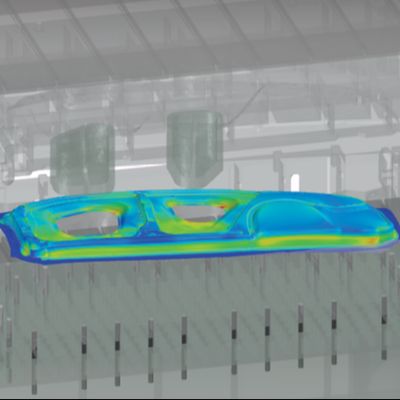

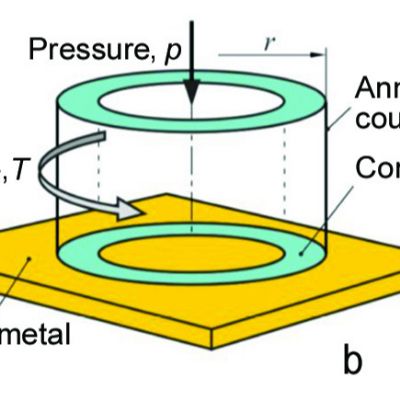

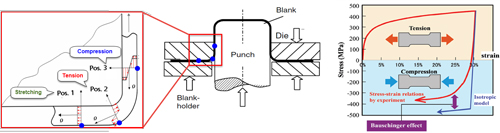

| Fig. 1—These diagrams describe the Bauschinger effect, where sheet material flowing on the tooling interface undergoes complex strain-path changes such as tension to compression, or vice versa, during several loading and unloading cycles. Simulation that successfully addresses springback account for this effect. (Left illustration courtesy of D. Banabic et al., Sheet Metal Forming Processes: Constitutive Modelling and Numerical Simulation, 2010, p. 122 and p. 126. Right illustration courtesy of T. Yoshida et al., “Material Modeling for Accuracy Improvement of the Springback Prediction of High-strength Steel Sheets,” Nippon Steel Technical Report No. 102, January 2013.) |

Of chief concern when forming these lightweight materials is springback—undesired shape changes in a formed part due to recovery of elastic deformation after the tooling opens. In AHSS, springback results from high yield stresses, and in aluminum alloys from a lower young modulus.

The accuracy of results from sheet metal forming simulation strongly depends on the material model characteristics that include the elastic property range and plastic property deformations, represented by the hardening curve and the yield surface, according to Demiralp. In addition, the stress and strain state during the forming process and after tool opening must be simulated accurately in order to achieve reliable springback prediction.

|

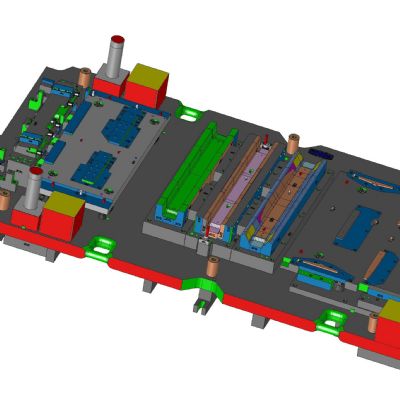

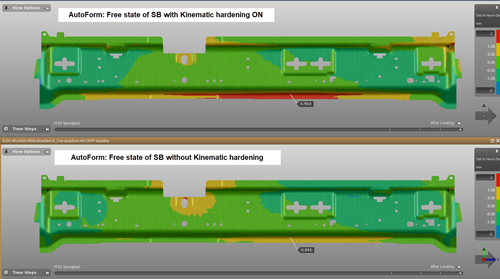

| Fig. 2—Simulation of the forming of an automotive rear cab reinforcement part, produced from DP600 advanced high-strength steel, reveals how the use of kinematic hardening modeling accurately predicts springback. Performing this simulation early in tool design enabled Atlas Tool to produce tooling without the need for expensive tool recuts. |

Strain hardening of sheet material differs under cyclic tension and displays a behavior commonly referred to as the Bauschinger effect, also known as kinematic hardening (Fig. 1). Consideration of kinematic hardening, mainly a transient softening of sheet material and, more importantly, degradation of Young’s modulus, says Demiralp, increases the accuracy of springback prediction in sheet metal forming simulations. Isotropic hardening does not consider the Bauschinger effect, thus lowering the quality of springback prediction.

AutoForm has developed and implemented its own user-friendly kinematic hardening model, validated against physically determined cyclic tension-compression curves, as well as springback measurements. As a result, simulation provides reliable springback prediction even for complex geometries and materials, Demiralp says.

|

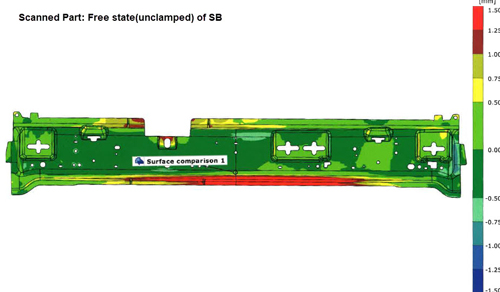

| Fig. 3—This scan of the actual physical panel matches the predicted panel that included consideration of kinematic hardening properties in addition to isotropic hardening properties, thus affirming the effectiveness of such simulation. |

The simulations produced springback-prediction results, with draw tools compensated accordingly in order to produce parts compliant with defined and desired dimensional tolerances for the final reinforcement part (Fig. 2). The simulated springback results, employing kinematic hardening modeling, compared closely with actual measurements (Fig. 3), report Demiralp and Broadworth, noting that the results were significantly better than those based solely on isotropic hardening.

View Glossary of Metalforming Terms

See also: Autoform Engineering USA

Technologies: Software