What the Die Needs

November 1, 2011Comments

Since a tool cannot speak for itself, let’s use this forum to speak on its behalf in a court of technical jurisdiction. The tooling can be a progressive or transfer die—we will not discriminate as we come to its defense and clearly state to the technical jury what a die needs, at a minimum, to function properly.

Feed

All dies expect to close on top of a properly positioned strip or blank. I know of no die designer who has a casual, cavalier attitude about this. On his CAD system, the designer conceptualizes, designs and details a die under the assumption that everything outside and inside of its internal and external surfaces will arrive as specified. Then, the strip or blank must be presented to the die within these expectations, in order for the tooling to consistently form good parts. In the case of a progressive die, the strip must arrive at the die within the corrective tolerance of the pilots. So, for example, if the feed pitch for a progressive die is 4 in. and the pilots allow for a misfeed correction of ±0.020 in., then the die must not be allowed to close if the feed pitch exceeds that tolerance range. Period. Even if the pilots were to be forced to correct for such serious out-of-tolerance feed errors, the stamper risks compromising part quality and will experience premature die wear.

The same holds true—maybe more so—for transfer tooling. Unlike a progressive die, where the entire strip must feed properly by a single feeding mechanism, transfer tooling expects the transfer arms to position each blank so that it seats or nests properly within the respective lower die components, to ensure proper forming, bending, piercing etc. Once the transfer arms release their blanks, the blanks may become unstable and their movement unpredictable. Once the gripper fingers on the transfer arms let the blanks go, there may be little confidence that they will fall into their expected lower-die nesting positions. Just for a moment, in defense of the transfer die, let’s consider each transfer operation as an independent feed mechanism. This means that if the die has 16 stations, it’s considered to have 16 unique feed mechanisms, each one independently capable of releasing the blank into an unstable flight path.

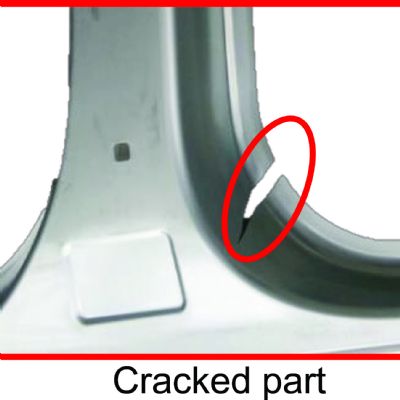

Part Ejection

In further defense of dies, let’s address the fact that each and every part is expected to exit its outside perimeter in an orderly and predictable . In a progressive die, the last station expects the finished part to promptly index out of the of the following part. And we expect the same with a transfer die—stations must properly evacuate to make room for the next blank. Last time I looked, no die-design CAD package features an icon marked, “Double Hit.” Yet, throughout my 25-plus years of consulting, I’ve continued to hear stampers plead their case: “This die can take a double hit,” I hear. How do they know this? Other than a rough guess involving the size of the die and the tonnage capability of the press, how dare anyone insult his or her tooling by stating that it can properly close on top of two or more stacked parts, and consider this an acceptable practice?