Industry 4.0 Applications in the Sheet Metal Forming Industry

March 27, 2025Comments

The term Industry 4.0 describes the latest sensor, communication, data-storage and connectivity (such as Internet of Things, or IoT) technologies used in manufacturing. For sheet metal forming, we can summarize Stamping 4.0 as:

- Understanding the incoming material properties

- Adjusting the press and automation based on the data

- Checking if the parts are as expected and within tolerance.

For example, a North American OEM uses Fraunhofer’s 3MA (micromagnetic-multiparameter, microstructure and stress-analysis) sensor to estimate the YTE (yield and tensile strengths, and elongation) of its incoming material. It also uses a laser scanner to check blank thickness to within ±0.02 mm, and another Fraunhofer sensor to scan the lubrication on the sheet, to within ±0.05 g/m2. Based on this incoming data, and a database developed from FEA simulation, the appropriate cushion forces are calculated. The final part draw-ins are vision-controlled using a Selmatec vision-based monitoring system.

For example, a North American OEM uses Fraunhofer’s 3MA (micromagnetic-multiparameter, microstructure and stress-analysis) sensor to estimate the YTE (yield and tensile strengths, and elongation) of its incoming material. It also uses a laser scanner to check blank thickness to within ±0.02 mm, and another Fraunhofer sensor to scan the lubrication on the sheet, to within ±0.05 g/m2. Based on this incoming data, and a database developed from FEA simulation, the appropriate cushion forces are calculated. The final part draw-ins are vision-controlled using a Selmatec vision-based monitoring system.

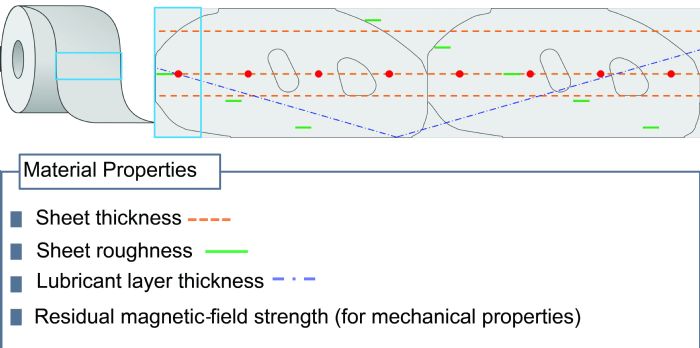

In another case, a German OEM uses residual magnetic-field strength as the incoming material property, rather than estimating YTE. During blanking, it measures the sheet thickness in three different lines, sheet roughness on five different sections and lubrication on a linear pattern (Fig. 1). Then each blank is marked for identification.

In another case, a German OEM uses residual magnetic-field strength as the incoming material property, rather than estimating YTE. During blanking, it measures the sheet thickness in three different lines, sheet roughness on five different sections and lubrication on a linear pattern (Fig. 1). Then each blank is marked for identification.

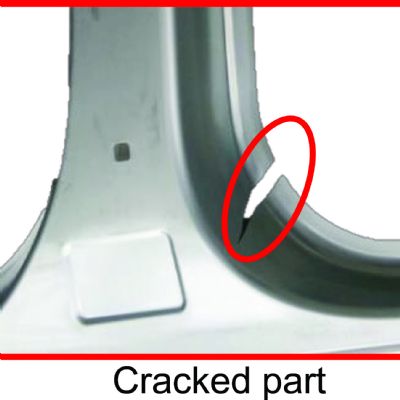

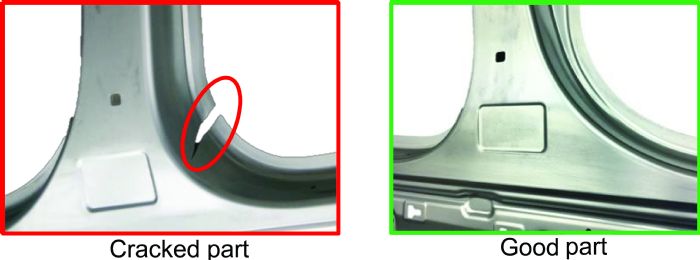

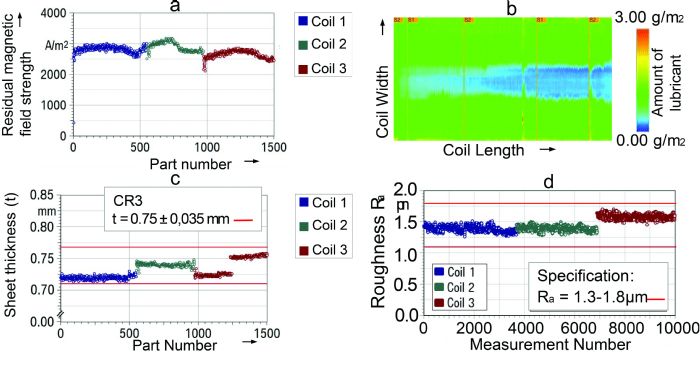

For this particular body-side outer, the potential crack occurs at the lower end of the B-pillar (Fig. 2). Analysis reveals that the raw data fluctuate between coils and also within a coil. Fig. 3 illustrates some of the measurements. To alleviate cracking, rather than adjusting cushion force the OEM increased the amount of lubricant used.

For this particular body-side outer, the potential crack occurs at the lower end of the B-pillar (Fig. 2). Analysis reveals that the raw data fluctuate between coils and also within a coil. Fig. 3 illustrates some of the measurements. To alleviate cracking, rather than adjusting cushion force the OEM increased the amount of lubricant used.

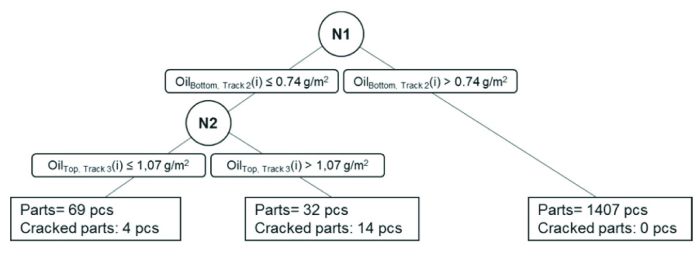

The same OEM performed another study to learn where cracks can be predicted based on lubrication in a given location (Fig. 4). When the amount of lubricant exceeded a specified threshold, no parts cracked. Therefore, the company added a control system to its lubrication setup.

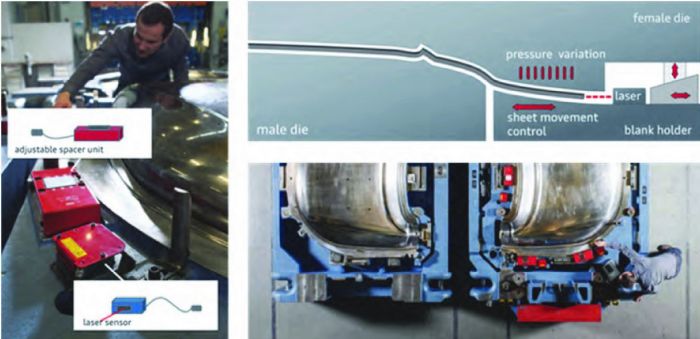

The same OEM performed another study to learn where cracks can be predicted based on lubrication in a given location (Fig. 4). When the amount of lubricant exceeded a specified threshold, no parts cracked. Therefore, the company added a control system to its lubrication setup.  Lastly, a Stamping 4.0 application at another German OEM involved stamping a hood outer from 6000-series aluminum. The material and its surface conditions tend to change from coil to coil, so the OEM designed a smart die that employs laser sensors to measure material draw-in (Fig. 5). If the material flows more than planned for the given press stroke, an adjustable spacer decreases the die spacing, and if the material flows less than planned, the adjustable spacer increases the die spacing. This ensures that all of the hoods have a similar draw-in after stamping, regardless of material variations.

Lastly, a Stamping 4.0 application at another German OEM involved stamping a hood outer from 6000-series aluminum. The material and its surface conditions tend to change from coil to coil, so the OEM designed a smart die that employs laser sensors to measure material draw-in (Fig. 5). If the material flows more than planned for the given press stroke, an adjustable spacer decreases the die spacing, and if the material flows less than planned, the adjustable spacer increases the die spacing. This ensures that all of the hoods have a similar draw-in after stamping, regardless of material variations.