Forensic Investigation—Press-Shop CSI

May 1, 2012Comments

Forensic engineering may be defined as the investigation of materials, products, structures or components that fail or do not function as originally intended. Vital to the field of forensic engineering is the process of investigating and collecting data—through collecting evidence, performing inspection, taking measurements, creating numerical models or performing experiments.

|

| Fig. 1 |

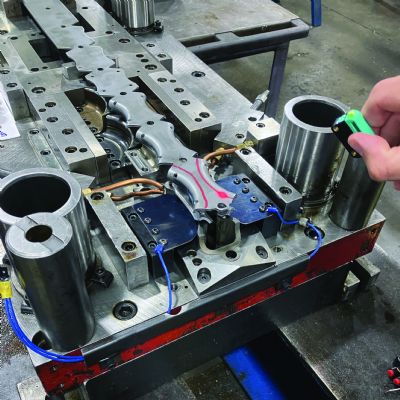

When a problem with a progressive die occurs, or when it becomes damaged, it is essential that engineers thoroughly investigate and analyze the strip. Unfortunately, many decisions are made in the press shop based on inspection reports, a die-maintenance log, past experiences, a supervisor’s opinion or any number of other reasons, rather than interrogating the eyewitness—the die strip. The strip can provide invaluable information with regard to the stamping process:

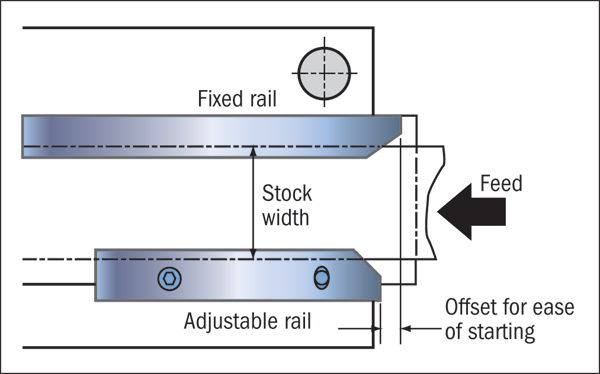

• Is the material feeding properly?

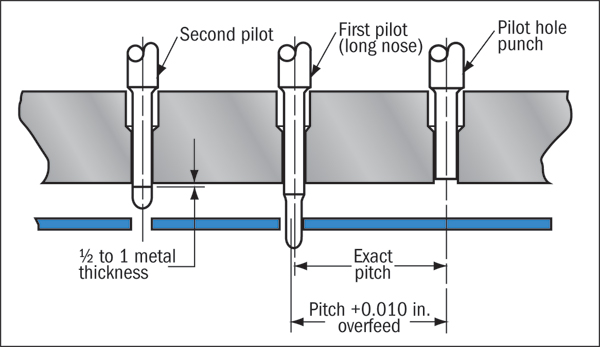

• Are the pilots positioning the strip accurately?

• Is the pitch length (the distance between the pilot holes) growing or shrinking beyond design specs?

• Is a stretch flange splitting due to a mismatched cut?

• Are extrusions splitting due to a burr?

• Is the die hitting too hard or not hard enough?

• Are deep-drawn features splitting due to restricted material flow or an incorrect radius?

• Is the carrier design appropriate?

• Is the die hitting level in all the stations?

• Is die timing correct when the die is fully loaded?

• Do cutting clearances change when the die is fully loaded?