Proper Press Settings from Run to Run

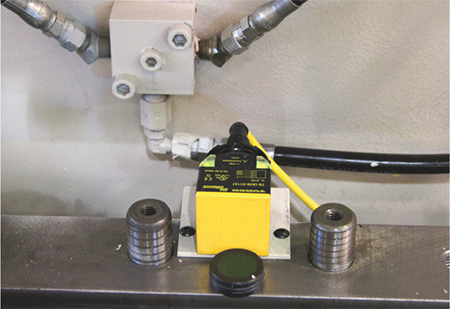

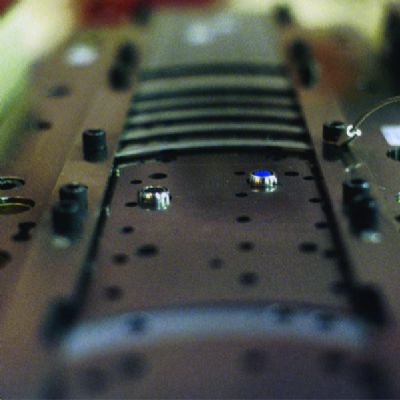

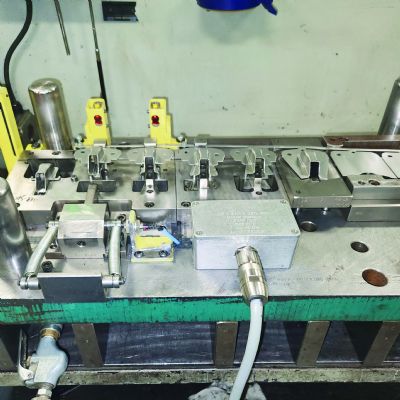

Greenerd also developed a program that allowed each die to be viewed with an RFID reader located on the throat plate of the press. The RFID system sends the die information directly to the control, which calls up the correct program for that particular part run and inputs the proper press settings. A job doesn’t run until the control has read the dies and determined that the die halves match.

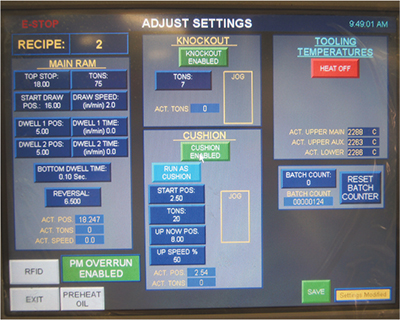

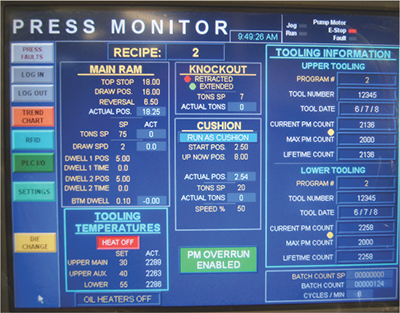

The upgrade also included installation of a pressure and linear transducer, enabling control of stroke depth and tonnage via the touchscreen. Recipes via these readings then can be stored for future access, ensuring proper settings job after job.

Preventive Maintenance Assured

When production ends, the touchscreen displays the total number of cycles run using the die, and stores this information. It also notifies personnel of the number of useable cycles left on that tool—a low number triggers personnel to remove the die for service. Following maintenance, the control resets the cycle count for that die to zero.

Control Upgrade Brings Dramatic Improvement

Summarizing, the extensive control upgrade allowed the metalformer to:

• Accurately control how many cycles are run on each of the dies and cue personnel to perform preventive maintenance, minimizing the chances of a die problem during a production run;

• Eliminate the possibility of mismatched upper and lower dies, dramatically reducing die maintenance/ repair costs; and

• Ensure part production using the same press parameters from one run to the next, establishing guaranteed continuity in how the parts are produced and providing assurances that variables in the production process remain under control. MF

View Glossary of Metalforming Terms

See also: Greenerd Press & Machine Co.

Technologies: Sensing/Electronics/IOT, Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Industry 4.0 Applications in the Sheet Metal Forming Industr...

Eren Billur March 27, 2025