10 Questions: How to Determine Which Type of Control to Outfit to Your Press

February 26, 2024Comments

A stamping press’s basic function and methodology have not changed much over the years, but the way that the press is driven and controlled has.

A stamping press’s basic function and methodology have not changed much over the years, but the way that the press is driven and controlled has. Press controls have advanced over the years, and their features and options have proliferated.

1. How have press controls advanced during the last few years?

A press controller’s main purpose is to control the motion of the press to ensure operator and press safety, ease press operation, and maximize productivity and quality, and that has not changed. Most press controls have been refined over time. The most significant advancement is auxiliary communication that allows press controls to connect and communicate with multiple pieces of equipment, including computer servers.

A press controller’s main purpose is to control the motion of the press to ensure operator and press safety, ease press operation, and maximize productivity and quality, and that has not changed. Most press controls have been refined over time. The most significant advancement is auxiliary communication that allows press controls to connect and communicate with multiple pieces of equipment, including computer servers.

2. How can a stamper choose the right control for its press operation? What should the stamper look for?

This would start with an evaluation of the stamper’s current production process, while considering future applications. The stamper should decide whether the standard features meet its needs, or if the control must be customized with options. Standard press control features should include:

- Fully programmable color touchscreens

- Easy-to-use settings

- A minimum of four die protection and process-monitoring inputs located in the operator terminal, with nine monitoring modes available for each die protection input

- Four programmable-limit-switch outputs to sequence and time automation with the press

- At least 56 control inputs and eight sets of dual-tracking safety control inputs

- Stopping-time-performance (brake) monitor, motion detection and clutch-engagement-time monitor

- Stroking modes with, at minimum: off, inch, automatic timed inch, setup/stop-time test, single stroke (cycle) and continuous

- 100-job-capacity storage and recall

- Nine-digit counters for stroke, parts, batch and quality

- Redundant safety dual-microprocessor logic systems.

Optional features may be needed or preferred to accommodate growth and future needs:

- Larger touchscreen

- Alternative languages, such as Spanish

- Additional job storage, to 1000 jobs

- Additional die protection/process-monitoring inputs and programmable-limit-switch outputs

- Additional modes, such as automatic single stroke (cycle), maintained continuous and continuous on demand.

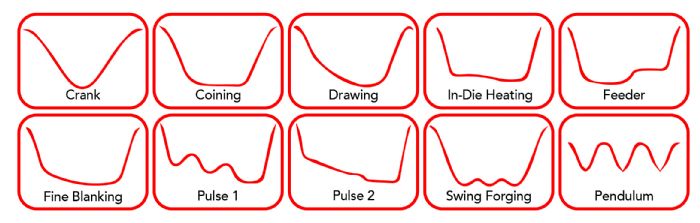

One of the biggest differences between mechanical and servo press controls is the use of cam-based functions. These typically use linear distances during stroking instead of angle-based settings, as servo presses have many more special stroke profiles that traditional mechanicals can’t perform.

One of the biggest differences between mechanical and servo press controls is the use of cam-based functions. These typically use linear distances during stroking instead of angle-based settings, as servo presses have many more special stroke profiles that traditional mechanicals can’t perform.