QA Systems for Automotive Steel Lines

November 1, 2017Comments

EMG Automation delivers products for online measurement of material strength and oil-layer thickness in the automotive sheetmetal production and processing industries.

The company’s magnetic-inductive measuring system provides nondestructive online determination of tensile and yield strength. The technology is based on measurement of the magnetic properties of ferritic steel grades. Magnetic values correlate with the destructive test results already obtained in production, and mathematical models deliver accurate absolute values for the material properties. The result is an online look at tensile and yield strength throughout the coil.

EMG recently introduced two systems to ensure reliable determination of oil-film thickness, which may change during the production process, and require an intermediate measurement of oil-layer distribution. The EMG Solid IR, based on infrared absorption spectroscopy, emits an infrared light that passes through the oil layer, scatters back from the stip surface and passes through the oil layer again. The unit measures intensity of specific wavelengths of the oil layer, and calculates the layer thickness.

Secondly, the EMG Solid LIF, based on laser-induced time-integrated fluorescence spectroscopy, offers low sensitivity against varying surface characteristics and inhomogeneous oil distribution on a microscopic level. Determining which technology to use depends on an EMG analysis of the lubricants and material surfaces for each application.

Users of the Impoc and Solid IR/LIF systems receive coil maps showing material properties and oil layers over the coil or sheet surface, which helps ensure that user specifications for companies such as BMW are met.

As early as 2006, BMW was looking for products for online measurement of surface roughness, oil-layer thickness and material properties in the stamping process. EMG provided two systems: Sorm 3plus for online roughness measurement and Impoc for strength measurement. Both systems are operating in BMW’s lines in Regensburg, Germany.

Today, more than 55 EMG Impoc systems are used in hot-dip galvanizing, continuous annealing, and pickling lines, as well as pressing and blanking lines in the automotive industry.

EMG Automation: www.emg-automation.com

View Glossary of Metalforming Terms

See also: EMG Automation Gmbh

Technologies: Quality Control

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Quality Control

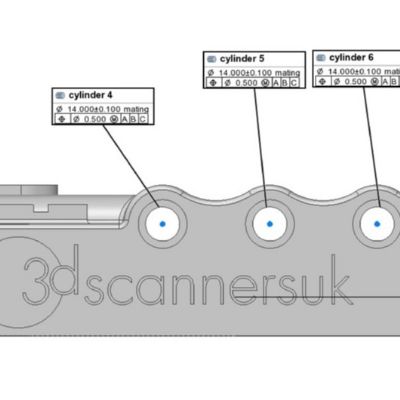

Quality ControlOnline GD&T Training

Tuesday, October 29, 2024

Use Lean Six Sigma for Efficiency & Quality Improvement

Daniel Schaeffler Friday, October 27, 2023

Management

ManagementSeeking Small Victories: Continuous Process Improvement

Daniel Schaeffler Monday, September 25, 2023

Quality Control

Quality ControlAn Introduction to Quality Management Systems

Daniel Schaeffler Thursday, July 27, 2023