Safety Breeds Success

You can’t discuss E.J. Ajax and Sons for too long before the subject of workplace safety comes up, as its safety record is well documented and publicized—more than 21 years without a lost-time on the job injury. “If we can’t be safe, we can’t be successful,” is the message Erick Ajax hammers home to his colleagues out on the shop floor. It’s a message that hits home with every single employee at the company, specialists in progressive-die metal stamping and metal fabricating. “The more we invest in our employees’ safety and in their professional development,” says Ajax, “the more they accomplish for themselves and their families, and for the company and its customers. It’s truly been an upward spiral for us.”

|

Meet Don Wellman, the company’s purchasing manager as well as an estimator and a key account manager—a far cry from when he was hired in 1999 as an entry-level class C punch-press operator, earning $8/hr. Wellman’s rise through the ranks included completing his Class A journey person training in 2004 and promotion to the front office as an estimator and key account manager in 2008.

“When we hired Don,” says Erick Ajax, “we got him from a temp agency, which used to be our standard practice for adding shop workers. That process would typically result in a 10-percent success rate, and Don was that one in ten that worked out.”

Once Ajax and other managers realized that Wellman was a “keeper,” they immediately went to him and asked that he invest his time to continue his education, at the company’s expense of course. He earned his GED and entered the company’s apprenticeship program. In 2006, Wellman earned recognition for his dedication when Red Wing Shoe Co. named him one of the top 100 skilled tradespeople in the United States.

“My first couple of years here, I focused on becoming the best press operator I could,” says Wellman, “and quickly came to understand how much this company cares about its employees and their families. Then, once I earned my journey workers card I began to look for other opportunities to learn and grow.”

One such opportunity came when Wellman decided to teach at Hennepin Technical College, at about the same time that the college fired up its M-Powered program.

“I taught the metal stamping technician class,” Wellman says, “which really helped hone my people skills and certainly helps me now as I work with our suppliers (as purchasing manager) as well as with our frontline workers, trying to understand their needs.”

Says Ajax: “Moving Don out of the pressroom was difficult. He was our best press operator. But now he’s able to contribute far more to the success of our customers and to our company.” Wellman, in addition to the technical training he’s received, is another of the several Ajax employees to complete Dale Carnegie training, and also earned his Certified Purchasing Manager certificate.

“The management team here seems to als be looking for the training we need to get us where we want to go,” says Wellman, “rather than just focus on where we are. I really appreciate that.”

Thinking ahead, Wellman vows to strengthen his skills in marketing and sales, and in fact already has a head start as he recently landed a new, big customer for the company. “Don single-handedly negotiated a contract for us to provide fabricated-metal products for the retractable roof of the new Florida Marlins baseball stadium,” says Ajax. “He’s owned that project, and I’m sure that he’ll continue to help build our customer base as he gains more experience and training.”

|

Ajax stresses that his company—essentially a contract manufacturer serving OEMs in numerous industries including appliance, commercial construction, truck, HVAC and hardware—competes not only domestically but globally, and that as such, “our skilled metalforming professionals can safely create the same value as 20 Chinese workers…By working safely and productively, we drive quality up and costs down. Our associates, many of them recruited from low-income and under-served populations, enjoy a high standard of living and add to the economic vitality of the community.”

Erick Ajax joined his family’s business in 1984 working in sales and human resources and, he shares frankly, that he didn’t like what he saw in terms of how the company went about its business on the shop floor. “It was unsafe,” he recalls, “and unprofessional, and I worked with my father (running the company at the time) to fix all that was broken.”

As step one on his journey to remake the company, Ajax immediately set out to forge a close bond with the Minnesota Department of Labor and Industry (MNDOLI). His goal: to build a program for professional development, education, and training, tying closely workforce development and safety. “Safety is our highest moral and ethical responsibility,” Ajax says. “That’s why we have partnered with MNOSHA consultation for more than 25 yr.”

During the last 15 years, the company has invested an average of 5.5 percent of payroll on workforce-development initiatives, key to forging Ajax’s vision of an esprit de corps. Ajax repeatedly refers to his frontline colleagues as “professional metalformers,” and, he adds, “professional metalformers do not get hurt on the job.”

Career Ladders in Place

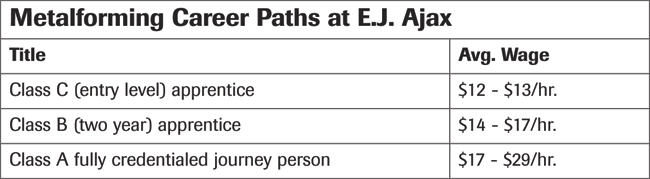

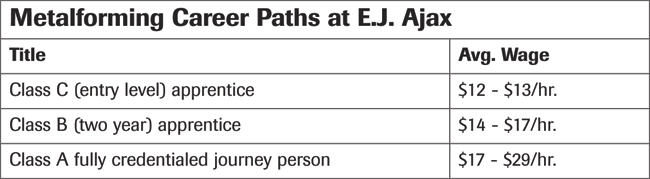

The pot of gold at the end of the proverbial training rainbow came in the early 1990s when Ajax collaborated with the MNDOLI to develop an 8000-hr. punch-press apprenticeship program, a first for Minnesota. With a curriculum consistent with the skill standards of the National Institute for Metalworking Skills (NIMS), the program can cost Ajax $20,000 to $30,000 per employee in direct and indirect costs; to date, 61 percent of E.J. Ajax employees have achieved Class A journey worker Level III status, and many have two or more NIMS Level III certifications.

“We insist that people get on a career ladder, develop their skills and create value for our customers.” Ajax says. “Shame on me if we can’t do a good job providing opportunities for personal advancement and achievement for our trained employees.”

As a result of the commitment Ajax employees make to upgrade their skills, they earn 15 to 20 percent more than the national average, says Erick Ajax. Average Class A Journey worker wages at the company are $40,000-$50,000/yr. Such a skilled and loyal workforce (the company has had only one employee leave voluntarily in the last 10 years) pays tremendous benefits as the company strives to optimize productivity, quality and, yes, safety, all to ultimately generate earnings for its customers.

“Our single-most important strategy for retaining customers is to help them make more money,” stresses Ajax. “Our commitment to our customers—along with 100-percent quality and on-time delivery—is an annual cost reduction of 5 percent, achieved by involving customer purchasing and engineering. And we often exceed that goal, with reductions of 10 to 15 percent. We accomplish this through innovation and value engineering, and often those innovations derive from our skilled workers on the shop floor.”

Full Participation in Lean

During the last 10 yr., Ajax employees have submitted more than 1000 documented continuous-improvement (CI) suggestions, an average of more than 100 suggestions/yr. Ajax describes a particularly rewarding suggestion from a frontline worker regarding fabrication of an assembly for a key customer. The suggestion: fabricate the assembly from prepainted steel, rather than sending the work out for powder coating after fabrication. The new process, in place since early 2010, has saved the customer more than $500,000 to date.

While most manufacturing companies tout employee-led continuous-improvement efforts, few can boast of achievements similarly to E.J. Ajax, which just recently achieved 100-percent participation in its lean training and participation in lean projects. Says first-shift production supervisor Rob Duvall: “Our lean projects are designed so that our colleagues on the shop floor learn from each other, not from me. They create their own value-stream maps, and contact vendors if new equipment might be needed to complete a project. We’re certain that the level of involvement and excitement we get from our frontline workers is born from the amount of time and money we invest in their education and development.”

|

| “Our lean projects are designed so that our colleagues on the shop floor learn from each other, not from me,” says first-shift production supervisor Rob Duvall. “They create their own value-stream maps, and contact vendors if new equipment might be needed to complete a project.” |

Asked to describe a fresh lean project that paid immediate returns, Duvall describes an ambitious project to eliminate paper from the pressroom. “The assigned lean team determined what we were spending on the paperwork throughout the plant (for job travelers, data collection, etc.) and investigated technology options to eliminate it, such as computer hardware and software and bar-code scanners. Team members contacted vendors, gauged purchase price vs. projected savings, solicited (and received) front-office support and wound up investing around $20,000 for the project, with an expected return on investment of less than one year. We now have personal computers throughout the plant where operators can input and collect data using (Unisystem) recordkeeping software.

More CI from the Shop Floor

Duvall also notes a recent CI project involving purchase of new capital equipment, spearheaded by Class A journey worker and tool and die maker Brad McKnight. Hired as an apprentice tool and die maker in 2005 following his service in the Marine Corps, McKnight used the GI Bill during a 4-yr. tool-making apprenticeship, and graduated with honors earning an Associate’s degree from Hennepin Technical College. While in school, he gained experience on a CNC milling machine, and recommended that the E.J. Ajax management team invest in the technology.

“Brad was instrumental in convincing me and others on our management team to make the capital investment in a new CNC mill,” says Erick Ajax. “We acquired the machine in 2009 and it’s already paid for itself.

Asked how working for E.J. Ajax has benefitted his family of a wife and two young children, McKnight is quick to point to opportunities to continue his education, announcing his plans to earn a degree in business management, get more involved in engineering and to eventually take on more of a supervisory role at the company, “thanks to the company’s generous 100-percent tuition-reimbursement policy” says McKnight. “In addition, the safety culture here obviously means a lot to my wife, reassuring her that I will come home every day safe and sound. And, last but not least, my wages have nearly doubled since I started working here 6 yr. ago.”

|

| Class A journey worker and tool and die maker Brad McKnight was hired as an apprentice tool and die maker in 2005 following his service in the Marine Corps. He used the GI Bill during a 4-yr. tool-making apprenticeship, and graduated with honors earning an Associate’s degree from Hennepin Technical College. |

Class A journey worker Dan McGee also has doubled his hourly earnings since joining E.J. Ajax in 2004, as a student intern. McGee quickly moved into the toolroom, then into the firm’s fabrication department where ne now serves as team leader. He earned his Class A journey worker’s certificate in sheetmetal fabrication early in 2011, and is more than half through earning a 4-yr. degree in business management at Augsburg College—all paid for through the E.J. Ajax tuition-reimbursement program.

Most recently, Ajax named McGee a key account manager for the company’s oldest and best customers. “I do quoting for them, and manage all of their work through the plant,” says McGee. “I now carry a smart phone while I’m working in the fabrication department, so I can monitor e-mails from the customer and make sure their requests are tended to as quickly and efficiently as possible. Time is critical, as they are a short-lead-time, high mix, short run customer.

“I really enjoy having close contact with the customer,” adds McGee, “and I’d like to progress into business management and sales at E.J. Ajax.”

Workforce Development on Behalf of All Employers

Erick Ajax knows an A-team employee when he sees one, and does all he can to make sure he never loses one. In an open letter to President Obama in 2009, he wrote that the “real strength of the United States lies in its middle-skill workers…who require more than high school but less than a 4-yr. degree. These jobs employ workers who manufacture goods to a standard of quality and productivity unrivaled anywhere in the world…These are also the workers who are already in short supply, and who will become scarcer.”

|

| Class A journey worker Dan McGee has doubled his hourly earnings since joining E.J. Ajax in 2004 as a student intern. McGee quickly moved into the toolroom, then into the firm’s fabrication department where he now serves as team leader. |

Proving that actions speak louder than words, Ajax joined a handful of Minneapolis manufacturers to become, in 2005, a founding partner in a fast-track manufacturing-training program called M-Powered. It was funded by The Hitachi Foundation and the Charles Stewart Mott Foundation, through the Manufacturing Institute of the National Association of Manufacturers and the Precision Metalforming Association Educational Foundation. Trainees take part in a 12-week industry-specific course at the technical college, and also receive career counselling, mentoring and job-placement assistance from HIRED. Ajax and other local metalformers participate in curriculum and program design, develop criteria for enrollment and ensure that its graduates’ capabilities match the current demand for new employees. Training occurs at Hennepin Technical College (with campuses in Eden Prairie and Brooklyn Park, MN). A three-part program that lasts typically 9 months provides students an opportunity to earn $12-$14/hr. “with little or no manufacturing experience,” says the M-Powered mission statement.

M-Powered is a joint effort between Hennepin Technical College and the local workforce-development organization Hired, currently funded by the U.S. Department of Labor. Hired provides job-skills training and employment training to Twin Cities-area low-income adults, dislocated workers, welfare-to-work people and other disadvantaged people.

|

Meet Althea DrePaul, Class B apprentice machine operator and 2008 graduate of the Twin Cities’ M-Powered manufacturing career-development program. “Through M-Powered and Hired, I now have a skill set I never thought I’d have,” says DrePaul. I’ve been given all of the skills I need to be successful—the opportunities are there, I just have to grab them.”

DrePaul emigrated from Guyana in 2001 and worked in the home healthcare industry for several years before being laid off in 2006. As a machine operator at E.J. Ajax, she earns twice what she earned in home healthcare, and also boasts about the company’s benefits program, including 100-percent tuition reimbursement as well as a 401k plan, life insurance and a generous contribution to her health-savings account.

In addition to DrePaul’s responsibilities on the plant floor, where she partnered with another operator to earn Ajax’s 2011 5-S project of the year recognition, DrePaul also acts as vice chair of the safety leadership team. As such, she played a vital role during the company’s recertification efforts with the MNSharp (Minnesota Safety and Health Achievement Recognition) program, supporting the firm’s director of employee safety Neng Yang.

“Serving on the safety leadership team and working with Neng on recertification brought a lot of pride and joy in my work,” says DrePaul. “My colleagues respect me, and I respect them. We look to each other for advice, to make the workplace a better place for all of us. It’s an honor to work here and to be involved in the development of our safety culture.”

As he does with several other employees, Erick Ajax sees a bright future for DrePaul, and she can’t wait for the opportunity to live up to his expectations.

“They (Erick Ajax, Kent Djubek and the rest of the management team) see something in me I had not seen in myself, until now,” says DrePaul. “I’ll continue to put my best out there, and wherever they want me to grow and develop, I’ll do it.

“Lately, I’ve been taking computer classes, so maybe I’ll be moving into the office soon. Just another wonderful opportunity.”

|

“We’ve hired a dozen graduates from the M-Powered program,” boasts Ajax, “nearly all of whom had never before worked in manufacturing. So far, six of those graduates have earned four year class A journey worker certification with nationally recognized NIMS metalforming-skills credentials. We even have operators teaching courses there now.”

Giving Back

Based on the notion that a trained employee represents the best investment a manufacturer can make, in return the E.J. Ajax management team only asks in return employees’ commitment to strengthening the company’s bottom line. “We want them to work with their brains as well as with their hands, to develop new ideas and then actively express those ideas to their peers and to management,” says Duvall. “This we nurture an environment where employees care about the company and its success, and they realize how closely their own success is directly tied to the company’s success.”

Just how closely? Consider, for example, the company’s stellar safety record and its financial ramifications. Annual costs for workers-compensation insurance averages a mere $800/ employee, compared to the industry standard of $2000-$4000 per year per employee. Ajax splits this savings down the middle with its employees, paying an annual incentive bonus of approximately $500 per employee per year. Ajax, discussing this benefit, adds that while the monetary benefits of working safely are obvious, the real payback “is knowing that our employees get to return home safely every day to their families.

“If an accident happens at work that prevents people from doing their jobs, it doesn’t only affect the workplace,” Ajax continues. “It affects their lives—the likelihood of divorce goes up, the chance of home foreclosure goes up, the chance of chemical dependency goes up, and the chance of becoming involved in criminal activity goes up. The human cost of a serious workplace injury is, simply, unthinkable.”

Conversely, Ajax contends, employees with positive and fulfilling personal lives make for better employees on the job. To that end, he encourages his frontline colleagues, as well as managers, to enroll in Dale Carnegie training, and more than 70 percent of the company’s employees have done so.

Helping to carry forth the company’s safety vision out on the shop floor is director of employee safety and second-shift supervisor Neng Yang, himself a Dale Carnegie graduate. Hired in 2005 as an entry level Class C punch press operator, Yang underwent rigorous training through the M-Powered program and became a Class A journey person punch-press operator in 2008, prior to being promoted to shift supervisor in late 2008. During that time his earnings have doubled. As director of employee safety, Yang recently led the company’s recertification efforts with the MNSharp (Minnesota Safety and Health Achievement Recognition) program.

“We’ve carried the certification for 10 yr.,” says Ajax, “important since it exempts us from random OSHA inspections.”

Process Innovations Aplenty from the Esprit de Corps

We asked numerous employees about the Ajax esprit de corps, and its effectiveness based on the company’s commitment to workforce development and safety. Across the board, they note fewer mistakes on the plant floor, a higher level of professionalism and pride, and increased self respect that leads to a commitment to one another and the company. Among significant achievements noted, directly tied to continuous training:

• Production of the firm’s key product increased from 4000 parts/hr. to more than 10,000 parts/hr.

• Setup times for progressive stamping dies have been reduced from an average of 2 hr. to less than 30 min.; and

• Quality of parts shipped has improved from 98.1 to 99.99 percent.

You can’t beat the perspective of company president and co-owner Kent Djubek, who Erick Ajax hired in 1990 as a temporary punch press operator on second shift, earning $6.50/hr. Promoted to fabrication team leader in 1993, first shift supervisor in 1996 and plant manager in 2001, Djubek’s earnings grew five-fold. In 2005 he became president and in 2007 became the first non-family stock holder, and is on track to purchase the company from Erick Ajax and his brother Tom in the next few years.

“My growth here is due completely to the company’s commitment to workforce development and training,” says Djubek, citing specifically coursework in leadership development and human resources. “Also key, believe it or not, was my Dale Carnegie training. These classes (to the tune of $1800 per employee) have helped me and others not only work better with each other but also with customers. Communication skills are greatly enhanced, helping build that A-team Erick talks about, the esprit de corps built on camaraderie and cooperation.”

|

| Helping to carry forth the company’s safety vision out on the shop floor is director of employee safety and second-shift supervisor Neng Yang, one of the firm’s several a Dale Carnegie graduates. Hired in 2005 as an entry level Class C punch press operator, Yang underwent rigorous training through the M-Powered program and became a Class A journey person punch-press operator in 2008, prior to being promoted to shift supervisor late in 2008. |

Among Djubek’s responsibilities is managing the firm’s CI process. “We divide the ideas into three categories—productivity/lean, quality and safety,” says Djubek, “and assign them to project teams. There are no monetary awards or other recognition needed to inspire creativity from our frontline, just the prestige and pride they all take in being professional metalformers out on the shop floor. That’s our reward as managers for the investment made in their professional development.”

It should come as no surprise that CI suggestions involving safety take top priority, but productivity and lean, as previously mentioned, have been top of mind for the last few years. In fact, the firm earned the 2008 SKD Automotive Group Productivity Award from the Precision Metalforming Association (PMA) for a frontline-worker-initiated CI project to eliminate nonvalue-added time between a particular customer’s orders and the required delivery dates. Long cycle times in production meant that the customer had to keep expensive inventory on hand. Now, E.J. Ajax doesn’t start to make the product until it receives the order, so that the customer’s overall costs are less and cash flow is not tied up in storing finished goods. The team worked through a total productive maintenance plan for the process and, as a result, uptime of a continuous-flow production cell exceeds 99.8 percent and the supply chain has been reduced from six weeks to four hours.

Recognition Comes Often

The transition made by E.J. Ajax & Sons from the dirty, dangerous days of metalforming in the early ‘80s to becoming a beacon of safe and productive manufacturing has not gone without notice throughout the manufacturing world. Recognition, including the productivity aw ard noted above, has come early and often for the company.

ard noted above, has come early and often for the company.

Most recently, Minnesota’s Manufacturing Alliance (MA) named E.J. Ajax & Sons Manufacturer of the Year 2011. The award recognizes manufacturers who “exhibit openness in sharing their experiences and information to strengthen fellow manufacturers,” said MA president Art Sneen. Activities earning the company such recognition included hosting a series of programs on “Building a Safe and Lean Culture in the Workplace,” attended by numerous Minnesota companies.

In addition, the U.S. Chamber honored E.J. Ajax and Sons in 2011 with its Blue Ribbon Small Business Award. “Winners of the Blue Ribbon Small Business Award represent the country’s finest business success stories,” says U.S. Chamber president and CEO Tom Donahue. “It is their dedication to strong business principles that will enable us to rebuild our nation’s economy.”

|

| Company co-owner Kent Djubek signed on in 1990 as a temporary punch press operator earning $6.50/hr. Promoted to fabrication team leader in 1993, first shift supervisor in 1996 and plant manager in 2001, Djubek’s earnings grew five-fold. In 2005 he became president and in 2007 became the first non-family stock holder. |

E.J. Ajax & Sons also received, in 2010, PMA’s Pitcher Insurance Agency Safety Award, recognizing (at the time) its more than 20 years without a lost-time injury, and more than seven years without an OSHA-recordable incident.

“The safety culture is strictly enforced,” the PMA safety committee wrote when presenting the award. “One violation within a 12-month period warrants a verbal warning, the second is put in writing and the third results in a one-day paid decision-making leave, when the employee is sent home to decide whether he/she can follow safety policies… The enforcement of safety policies includes random drug testing for all employees, including office employees and officers…Safety training is continuous, with an average of 10 hr. /employee annually.”

The investment Erick Ajax and his management team make in the workforce allows the company “to capture the hearts and minds of its employees,” says Ajax, “and truly want to work safely, as opposed to us telling them to work safely. They understand that professional metalformers don’t get hurt on the job—that’s the difference between a safety program and a safety culture.”

PMA also awarded, in 2007, its A.R. Hedberg Training and Education Award to E.J. Ajax & Sons, noting at the time that the company had “distinguished itself as a leader in training by becoming one of the first metalforming companies in the country to incorporate full National Institute for Metalworking Skills credentialing into all of its apprenticeship programs and career ladders…Every employee of the company,” the award committee found, “from top management to entry-level employees, is required to devote at least 100 hours to training each year. In addition, E.J. Ajax pays 100 percent of tuition for a range of courses that contribute to the culture and esprit de corps of the company, such as team building and cultural diversity classes…Through its agreement with the MNDOLI, E.J. Ajax compensates its employees as they achieve credentials at higher levels…Many participants in the journey worker training program can nearly double their entry-level wages in 5 yr.” MF

Case Study: McGregor Metalworking, Springfield, OH

Case Study: Pridgeon & Clay, Grand Rapids, MI

Technologies: Management, Quality Control, Safety

Metalformer E.J. Ajax and Sons, Fridley, MN, has worked hard to develop an esprit de corps—a manufacturing “A-Team” honed to create value for its customers. The net result is consistent, above-industry-average bottom-line profitability, ensuring that company management continues to invest in technology as well as in workforce development.

Metalformer E.J. Ajax and Sons, Fridley, MN, has worked hard to develop an esprit de corps—a manufacturing “A-Team” honed to create value for its customers. The net result is consistent, above-industry-average bottom-line profitability, ensuring that company management continues to invest in technology as well as in workforce development.