Demand-Flow Process Line for Manufacturing Furnace-Filter Housings

January 1, 2008Comments Hess Industries, Inc., Niles, MI, introduces its Demand Flow sheetmetal-fabrication process line for manufacturing families of furnace air-filter housings. The line manufactures two versions each of air-filter housings for seven updraft and four downdraft furnace configurations.

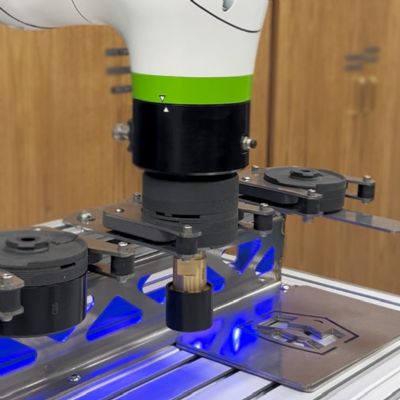

Furnace housings are manufactured on demand to customer orders. The process line integrates programmable servo-positioned punching, piercing, forming, shearing, wing bending and assembly stations to manufacture a family of different furnace-filter housing parts. The process line includes coil handling; material transfer (straight and part rotation); forming (fold and bend); and an accessory station (forming, assembly and fastening). A recent line for a major furnace manufacturer was programmed to produce 17 different filter-housing sizes, three for up-flow and nine for down-flow furnaces.

The Hess controller directs the feeding coil stock into a part-feature station where, depending on each panel’s unique configuration, separate dies are actuated by independent hydraulic presses. The part is cut to length and transferred to an edge-forming station and rotated 180 deg. to a flange-up position for assembly.

Next the part transfers into a subassembly station where preformed ribs are fed into position and joined to the inside of the panel frame. The frame then is transferred to a wing-bend station to form the final wrapper shape. Lastly, the part is fed into a final assembly station.

Hess Industries, Inc.: 269/683-4182; www.hessindustries.com

View Glossary of Metalforming Terms

See also: X

Technologies: Pressroom Automation

Video

Video