Metal Spinning Technology

June 25, 2019Comments

This article, the first of a series on metal spinning processes and tools, provides an overview of the technology.

Metal spinning is a near-net-shape forming process used to produce axisymmetric hollow parts, usually with circular cross-sections, that involves forming sheet metal over a rotating mandrel with the help of one or more rigid tools called rollers. The selection of rollers, available in different diameters, profiles, thicknesses and materials, including plastic, involves blank size, material type, product radii and desired surface finish.

|

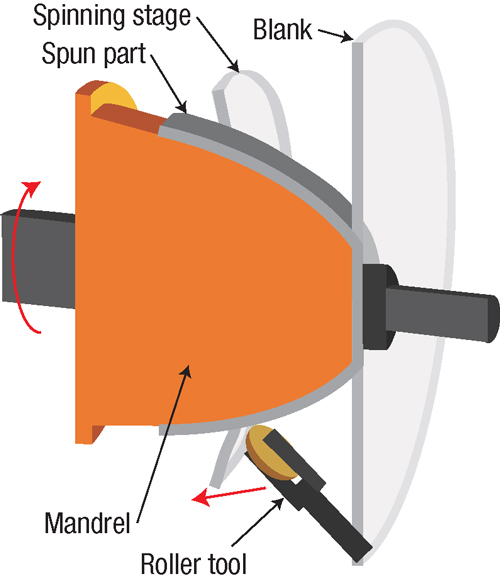

| Fig. 1—Forming action in metal spinning. |

Metal spinning imparts continuous localized plastic deformation through the feeding motion of the roller(s). Local material deformation in metal spinning—as opposed to global deformations in deep drawing—provides inherent advantages, including process flexibility, non-dedicated tooling, low forming loads, good dimensional accuracy and surface finish, high material utilization, low production costs, and improved mechanical properties.

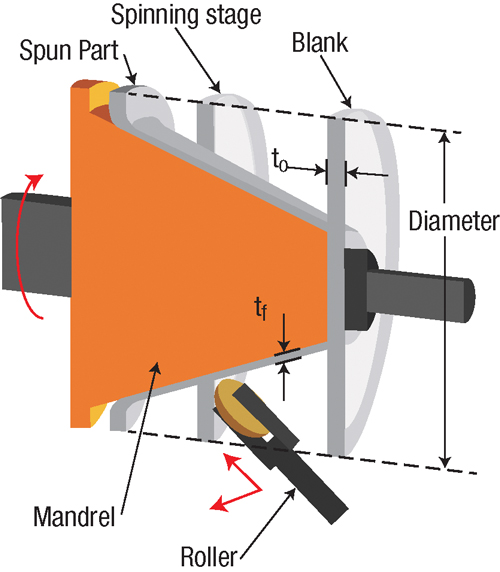

Metal spinning consists of three primary processes: conventional spinning, shear spinning and flow forming, with the primary difference between the three processes being the wall thickness after spinning.

Conventional Spinning

In conventional spinning, the wall thickness remains nearly constant throughout the process, with the final wall thickness of the spun part measuring about the same as the flat blank. A rotating sheet metal blank takes the shape of a rotating component called a mandrel through the application of localized pressure by a roller tool. The roller tool pushes on the blank as it follows a predetermined forming path consisting of multiple roller passes. The forming action continues incrementally until the inside of the formed part matches the contour of the mandrel (Fig. 1). Depending on part size, complexity, material type and quality requirements, it is sometimes possible to spin some parts with a single roller pass.

In multipass conventional spinning, the number of roller passes and direction of each pass determines the final wall thickness. When the roller moves forward, the material thins slightly; when it moves backward, it displaces metal in the opposite direction to ensure consistent wall thickness and reduce springback. Improving finish and accuracy may require intermediate and finishing passes, called planishing. Planishing passes, designed to remove waviness produced during the various stages in the spinning process, involve high feed rates to minimize tangential flow. A final roller pass enhances the surface finish by reducing the feed and speed while applying a relatively high radial force.

|

| Fig. 2—Forming action in shear spinning. |

Spinning can produce a variety of shapes, including domes, cylinders, cones and complex geometries consisting of a combination of these shapes. The finished diameters of spun parts are always smaller than the original blank diameters, but wall thicknesses remain the same as those for the blanks.

Forming stresses that cause yielding can determine spinning-process classifications. In conventional spinning, tensile-compressive stresses dominate, putting spinning in the same group of metal forming processes as bending and deep drawing.

Other types of classifications: mandrel and mandrel-free spinning, outer spinning (necking) and inner spinning (expanding), spinning with opposing rollers, cold and hot spinning, manual spinning, and CNC spinning.