Daniel Schaeffler

Daniel SchaefflerLimitations of Hardness Testing for Deep Drawing Applications

July 29, 2020Comments

Your sheet metal certifications may contain a reading documenting the hardness of the received product. For 1.5-mm-thick mild steel, the hardness probably will range from the mid to high 70s on the Rockwell B scale. But what does this value really mean?

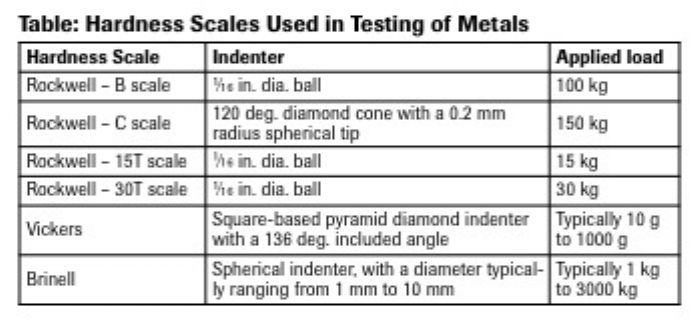

Simply, hardness represents a material’s resistance to indentation. Of course, this resistance varies among material types, but hardness-test results also depend on the size, shape and material of the indenter, and the amount of force used to push it into the sheet metal. The appropriate scale is a function of these testing parameters. The accompanying table displays the testing conditions associated with common hardness scales used in metal testing.

Simply, hardness represents a material’s resistance to indentation. Of course, this resistance varies among material types, but hardness-test results also depend on the size, shape and material of the indenter, and the amount of force used to push it into the sheet metal. The appropriate scale is a function of these testing parameters. The accompanying table displays the testing conditions associated with common hardness scales used in metal testing.

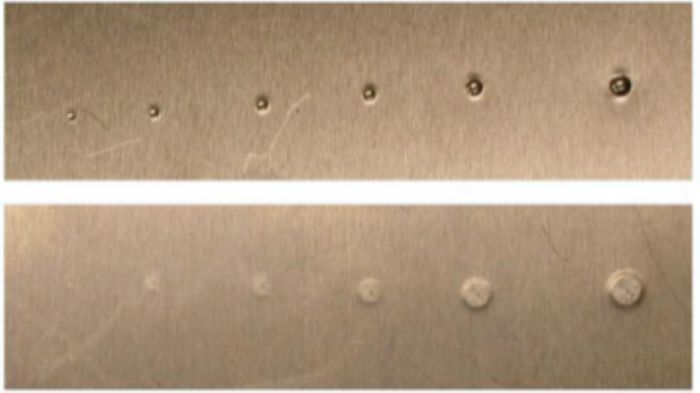

Determining Rockwell hardness values requires a two-step process. First, the test apparatus pushes the indenter (either ball- or cone-shaped) into the test-piece surface until reaching the desired preload (also called “minor load”) force—10 kg for the B and C scales, and 3 kg for the N and T superficial scales. This small initial penetration seats the indenter and provides a reference depth. Application of an additional “major load” results in deeper penetration into the sheet metal surface. Removal of the major load occurs, followed by a re-application of the minor load. The Rockwell hardness calculation defines the difference between this depth reading and the reference depth as “d” in the equation for the Rockwell B scale:

HRB = 130 – (d / 0.002 mm)

Per this equation, a hardness measurement of HRB 80 means that the indenter penetrated 0.10 mm into the metal, and 0.13-mm penetration occurrs on a metal with a hardness value of HRB65. Put another way, there is only a 30-micron difference in penetration depth between readings of HRB65 and HRB80. As a point of reference, the thickness of human hair is on the order of 100 microns. Another option for measuring hardness, the Brinell hardness test involves applying a specified load using a hardened-steel or tungsten-carbide spherical indenter of a specified diameter (typically 1 to 10 mm). To calculate the Brinell hardness number, we divide the load applied by the hemispherical surface area of the indentation. Measuring sheet metal hardness with Brinell tests is not common, due, at least partially, to the relatively high loads required and to the challenges of measuring a curved surface area.

An example of where this matters: Using the measurements described earlier in this article, a test providing a Rockwell B hardness reading of 80 or less on sheet metal less than 1 mm thick violates the ASTM requirements. Why? HRB80 indicates a 0.10-mm indentation depth―with lower hardness readings associated with increasing indentation depth. Ten-times this indentation depth is 1 mm, and any greater penetration violates the 10x rule; you’ll likely see the influence of the anvil in the test results. The applied load on the Rockwell B scale is 100 kg. Should a shiny spot appear on the underside of the test samples, switch scales to produce a shallower impression, potentially to the 30T scale, with a 30-kg applied load.

An example of where this matters: Using the measurements described earlier in this article, a test providing a Rockwell B hardness reading of 80 or less on sheet metal less than 1 mm thick violates the ASTM requirements. Why? HRB80 indicates a 0.10-mm indentation depth―with lower hardness readings associated with increasing indentation depth. Ten-times this indentation depth is 1 mm, and any greater penetration violates the 10x rule; you’ll likely see the influence of the anvil in the test results. The applied load on the Rockwell B scale is 100 kg. Should a shiny spot appear on the underside of the test samples, switch scales to produce a shallower impression, potentially to the 30T scale, with a 30-kg applied load.