Coming Soon: AHSS Application Guidelines, Online and Updated

March 26, 2020Comments

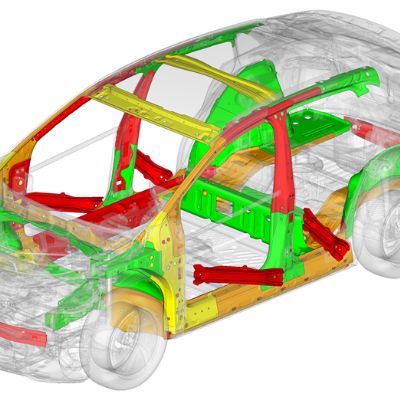

Advanced high-strength steels (AHSS) find use in nearly every vehicle on the market. Near-term projections indicate that these grades will soon comprise 60 percent of the typical automotive body structure. While these new steels offer many beneficial characteristics, they behave differently from other grades during forming and joining, and, therefore, require metal formers and other manufacturers to master the fundamentals and keep pace with process improvements being realized on the shop floor.

To guide users of these new and emerging products and help them navigate through these challenges, 22 steelmakers from around the world have been working together. Under the umbrella of WorldAutoSteel, they developed, nearly two decades ago, the Advanced High Strength Steels Application Guidelines, as early AHSS grades began transitioning from research to commercialization. In 2017, WorldAutoSteel released Version 6 of this document, which explains the unique characteristics of each grade, and presents global best practices for forming and joining AHSS.

To guide users of these new and emerging products and help them navigate through these challenges, 22 steelmakers from around the world have been working together. Under the umbrella of WorldAutoSteel, they developed, nearly two decades ago, the Advanced High Strength Steels Application Guidelines, as early AHSS grades began transitioning from research to commercialization. In 2017, WorldAutoSteel released Version 6 of this document, which explains the unique characteristics of each grade, and presents global best practices for forming and joining AHSS.

The next update of the guidelines, expected to be completed in 2021, will transform them into a mobile-friendly online database, which users can browse and search in order to quickly find specific information of interest. WorldAutoSteel will release the content to the public in several phases during the next 18 months. Even then, the knowledge database will never be truly complete. Having content posted online allows for uploading new and pertinent information as it becomes available, making the AHSS Application Guidelines a useful reference well into the future.

Updated Materials Portfolio

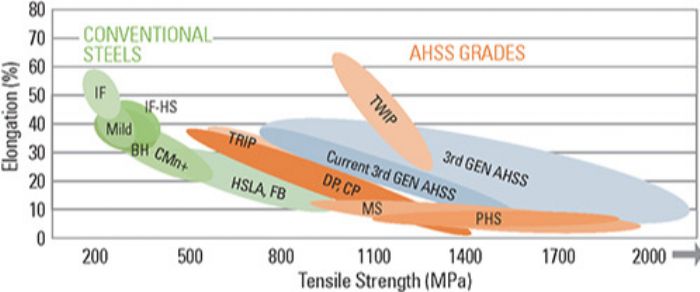

The new guidelines will contain a materials portfolio, listing available grades as well as those projected to be commercially available by 2021. The number of AHSS grades has more than doubled from the 20 listed in Version 4.1, released in 2009, expanding to higher levels of strength and ductility—as illustrated by the accompanying graph. The vertical axis of the graph represents total elongation—a measure of formability—with tensile strength represented on the horizontal axis.

The lower arc of the graph compares first-generation AHSS to conventional steels. Second-generation Twinning Induced Plasticity (TWIP) steels generally are not available in North America. And, third-generation AHSS grades, the most cutting-edge grades in use today, are with many more on the cusp of becoming commercially available and promise to be more formable at a given strength level than first-generation grades. They’re also less costly and more weldable than TWIP steels. The boundaries of each ellipse indicate the approximate range of properties for each AHSS grade.

In addition to strength and elongation, advanced steels can be tuned to optimize characteristics important for a specific stamped part. At a given strength level, separate grades may be available, offering either enhanced stretched edge flangeability, improved bendability or increased tensile elongation.