Technology Opens Door to Game-Changing Alloys for Steel Manufacturers

March 1, 2019Comments

A new technology from Kentwood, MI-based Arcanum Alloys, utilizing spatially optimized diffusion alloys (SODA ), is proving to be a disruptive innovation for steel usage, say company officials, pointing to three factors: designed performance, manufacturing versatility and greater functionality. Having first developed the technology in Silicon Valley before relocating to the Midwest to be closer to its suppliers and production partner, Arcanum has announced its first product: Optiform, a new stainless steel alloy; validated and tested with multiple customers. Arcanum expects its first production launch by April.

Formability

|

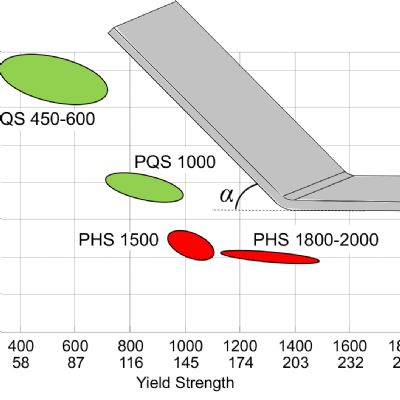

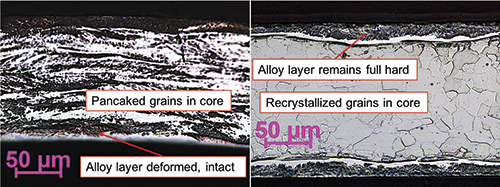

| The difference between recrystallization temperatures for the alloy layers and the recrystallization temperature of the core region makes it is possible to keep the alloy layer work hardened while recrystallizing the core alloy. |

While aesthetic differences may be indistinguishable, the material’s reduced scrap rates stand out. In standard operations, ferritic stainless work hardens substantially as it is drawn to form. Work hardening causes problems for OEMs such as springback, die wear, etc., leading to high scrap rates and program costs. The material’s customizable yield strength, high elongation and reportedly outstanding r-bar increases the range of design geometries—deeper draws and tighter radii.

Ultra-Thin Gauges

Optiform has been rolled to foil gauges for catalyst, thermal management and membrane support, to name a few current applications. Even as a foil, the mechanical properties, dominated by the ultra-low-carbon core, enable the material to maintain excellent ductility. This allows for the complex design forms often needed for catalysts and membrane supports to be imparted without tearing, or damaging production tooling. During rerolling to foil gauges, both the alloy layers and core are reduced equally, and both work harden. However, the magnitude of the delta between recrystallization-temperatures for the alloy layers and the substantial recrystallization-temperature of the core region make it is possible to keep the alloy layer work hardened while recrystallizing the core alloy (see image).

This unique combination of metallurgically bonded microstructures imparts a material with high stiffness but excellent elongation and corrosion resistant properties, typically difficult to produce. Manganese, often added as a strengthening element, represents another element demonstrated by Arcanum Alloys through its SODA platform. Light-gauge materials made with a full-hard-surface alloy high in manganese and a ductile core offer stiff steels with higher elongation than current high-strength low-alloy sheet products.

Customized Corrosion Resistance

The SODA platform allows Arcanum Alloys to customize the chromium content in the alloy at the surface of Optiform. Since corrosion resistance is tied largely to the chromium content of the alloy, Arcanum Alloys controls the corrosion resistance by controlling the chromium concentration in its alloyed surfaces. According to company officials, this spatial optimization brings multiple functionalities and tailored performance not attainable by other means.

For example, when customers require material to pass ASTM B117 salt fog testing, Arcanum Alloys alters its production slightly to increase chromium percentage in the alloyed surface. The majority of the Optiform produced now offers corrosion resistance between austenitic 304 stainless and 316 stainless grades, but the company also produces material for customers with corrosion performance needs greater than 316 stainless.