Part material includes the aforementioned high-strength stainless steels in the quarter-extra hard tempers, including Type 301 as well as 17-4 and 17-7 grades, along with Inconel. Penn United also stamps softer materials such as mild steels, aluminum, copper and brass.

Long-Term Success with Tool Coating

The effectiveness of coatings in extending tool life and mitigating part-quality issues became apparent to Penn United years ago, and has led to a long-term relationship with Phygen Coatings Inc., a Minneapolis, MN, coatings provider. Back then, in the mid-2000s, Penn United experienced galling on draws of Type 301 stainless steel. The company, aware of and following developments with various tool coatings, selected one particular coating, which was able to extend carbide-tool (most tooling in use at Penn United is carbide) life to 15,000 hits between recoating—an improvement, but Penn United was looking for more. So, the Penn United team tried Phygen’s FortiPhy chromium nitride physical-vapor-deposition (PVD) coating technology. To say that the company experienced improved results is an understatement, as Marraccini reports that after the switch “we instantly were able to run several million hits before tool failure and the need to have the components reworked and recoated.”

The effectiveness of coatings in extending tool life and mitigating part-quality issues became apparent to Penn United years ago, and has led to a long-term relationship with Phygen Coatings Inc., a Minneapolis, MN, coatings provider. Back then, in the mid-2000s, Penn United experienced galling on draws of Type 301 stainless steel. The company, aware of and following developments with various tool coatings, selected one particular coating, which was able to extend carbide-tool (most tooling in use at Penn United is carbide) life to 15,000 hits between recoating—an improvement, but Penn United was looking for more. So, the Penn United team tried Phygen’s FortiPhy chromium nitride physical-vapor-deposition (PVD) coating technology. To say that the company experienced improved results is an understatement, as Marraccini reports that after the switch “we instantly were able to run several million hits before tool failure and the need to have the components reworked and recoated.”

Phygen applies its patented FortiPhy PVD technology to create a thin and dense nanocrystalline coating structure onto any tool-steel substrate. Described by David Bell, Phygen president, the process creates a high level of adhesion. And, it does so without pulling carbon from the tools.

Temperature varies among the various tool-coating processes, according to Bell. Chemical-vapor-deposition coatings and thermal-diffusion coatings usually are applied at temperatures greater than 1800 F. Phygen’s coating requires significantly lower temperatures, he claims, lessening the chance of distortion that can play havoc with tolerances and minimizing tool-hardness concerns.

“Today, we utilize FortiPhy on progressive-die forming and drawing punches and dies, coining details, and some trimming details, with many of the resulting parts made from high-strength stainless steels,” Marraccini says, noting that the material for most of these parts range from 0.010 to 0.080 in. thick. “The main issues faced when forming and coining of these types of materials include galling and erosion of the forming and coining surfaces. And, in some aluminum-blanking applications, we add FortiPhy to again combat galling problems.”

Issues Identified, Fixed During Tool Design and Production

With its inhouse tooling expertise, Penn United is quite well-versed in determining, during design, the potential trouble spots in tooling where coating proves advantageous, or in identifying areas on current-production tooling that can benefit.

With its inhouse tooling expertise, Penn United is quite well-versed in determining, during design, the potential trouble spots in tooling where coating proves advantageous, or in identifying areas on current-production tooling that can benefit.

“Most of the time throughout our design reviews we'll have a good idea of what details may need to be coated, based on past experience with similar applications,” Marraccini says. “Here, we’ll have the tooling coated before we hit the die for the first time. Or, throughout the course of debugging a tool, we may see galling or premature wear on some details. Once identified, we’ll rework the details and send them out for coating. The same holds true when identifying issues in current-production tooling. Overall, we typically only coat surfaces that we feel will be problematic, or that we have later found to have issues with. For the most part, these include forming or coining surfaces and not trims.”

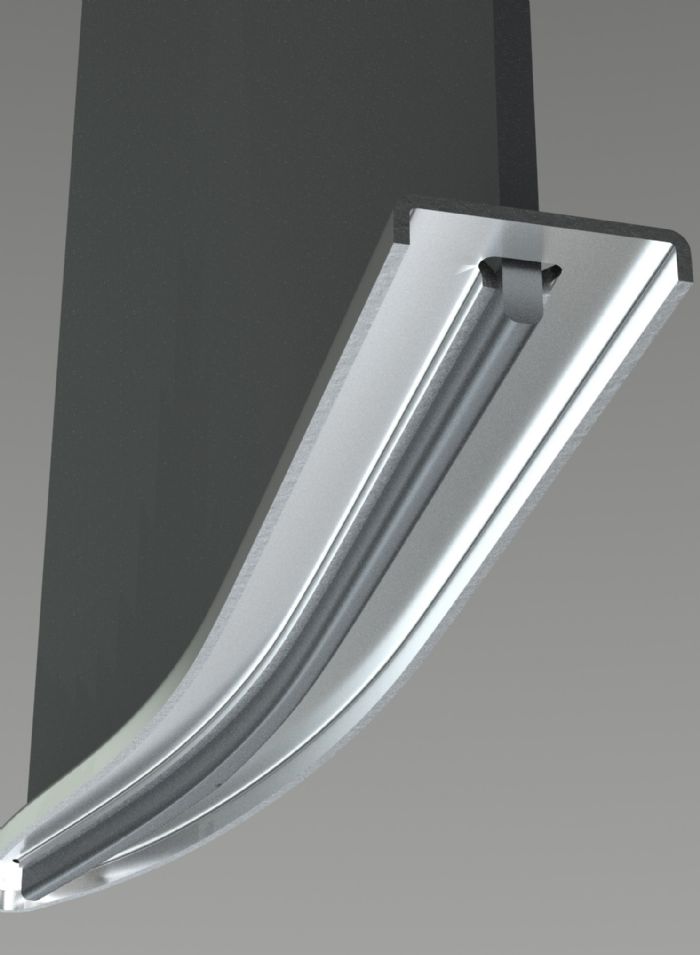

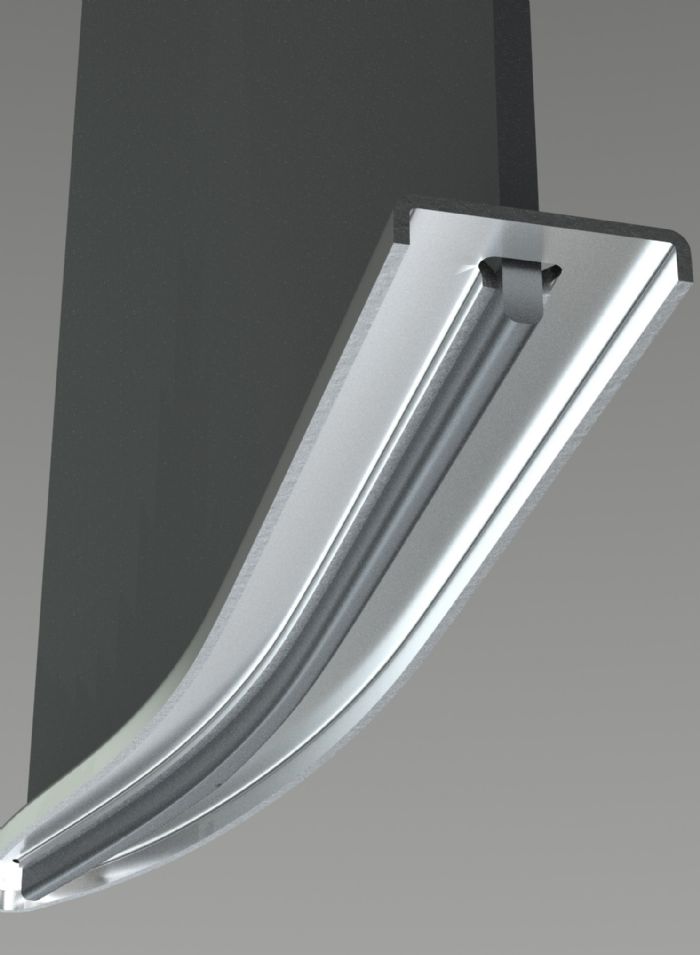

One recent job provided a particular challenge that led to a FortiPhy coating solution, according to Marraccini and Charlie Phillips, sales and marketing manager at Penn United. This involved a part produced from Type 301 quarter-hard 0.010-in.-thick stainless steel.

“The part features what we call a knife slot—a very thin slot through the center of the part,” Marraccini explains. “The forming punch for this slot, formed up 90 deg., is only 0.024 in. wide with a trim punch of only 0.014 in. wide. It’s a fragile piece of carbide tooling, and we found that upon reversal, the material really wants to grab the blade. Without a coating, over the course of only a few hits, the tool will break. The FortiPhy coating solved that problem.”

Quick Turnaround

Whether for tooling in development or production, lead time for coating always presents an issue. That said, Marraccini reports quick turnaround time with Phygen.

“Standard delivery time, which in most cases is acceptable, is one to two weeks,” he reports. “When we have a dire need, say, when a tool break holds up production or the debugging process, we can get same-day turnaround.” MF

Industry-Related Terms: Annealed,

Center,

Coat,

Coining,

Cross-Sections,

Die,

Drawing,

Forming,

Lead Time,

Run,

Stainless Steel,

Substrate,

TransferView Glossary of Metalforming Terms

See also: PHYGEN

Technologies: Materials

“In turn, our forming and drawing punches and dies experience more contact forces than in the past,” Marraccini says. “Also, using higher-strength materials eliminates the need for secondary operations such as heat treating. Some parts in the past were made from annealed materials and heat treated in a secondary operation. To reduce costs involved in a secondary heat treating process, these materials have been switched to higher-strength grades.”

“In turn, our forming and drawing punches and dies experience more contact forces than in the past,” Marraccini says. “Also, using higher-strength materials eliminates the need for secondary operations such as heat treating. Some parts in the past were made from annealed materials and heat treated in a secondary operation. To reduce costs involved in a secondary heat treating process, these materials have been switched to higher-strength grades.”

The effectiveness of coatings in extending tool life and mitigating part-quality issues became apparent to Penn United years ago, and has led to a long-term relationship with Phygen Coatings Inc., a Minneapolis, MN, coatings provider. Back then, in the mid-2000s, Penn United experienced galling on draws of Type 301 stainless steel. The company, aware of and following developments with various tool coatings, selected one particular coating, which was able to extend carbide-tool (most tooling in use at Penn United is carbide) life to 15,000 hits between recoating—an improvement, but Penn United was looking for more. So, the Penn United team tried Phygen’s FortiPhy chromium nitride physical-vapor-deposition (PVD) coating technology. To say that the company experienced improved results is an understatement, as Marraccini reports that after the switch “we instantly were able to run several million hits before tool failure and the need to have the components reworked and recoated.”

The effectiveness of coatings in extending tool life and mitigating part-quality issues became apparent to Penn United years ago, and has led to a long-term relationship with Phygen Coatings Inc., a Minneapolis, MN, coatings provider. Back then, in the mid-2000s, Penn United experienced galling on draws of Type 301 stainless steel. The company, aware of and following developments with various tool coatings, selected one particular coating, which was able to extend carbide-tool (most tooling in use at Penn United is carbide) life to 15,000 hits between recoating—an improvement, but Penn United was looking for more. So, the Penn United team tried Phygen’s FortiPhy chromium nitride physical-vapor-deposition (PVD) coating technology. To say that the company experienced improved results is an understatement, as Marraccini reports that after the switch “we instantly were able to run several million hits before tool failure and the need to have the components reworked and recoated.” With its inhouse tooling expertise, Penn United is quite well-versed in determining, during design, the potential trouble spots in tooling where coating proves advantageous, or in identifying areas on current-production tooling that can benefit.

With its inhouse tooling expertise, Penn United is quite well-versed in determining, during design, the potential trouble spots in tooling where coating proves advantageous, or in identifying areas on current-production tooling that can benefit.