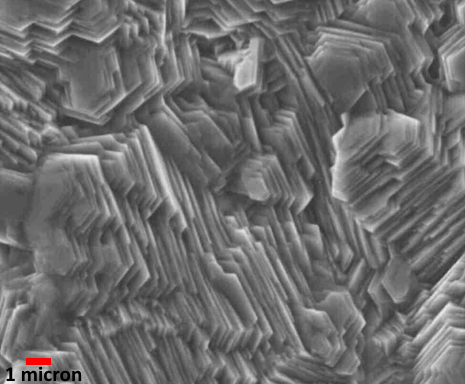

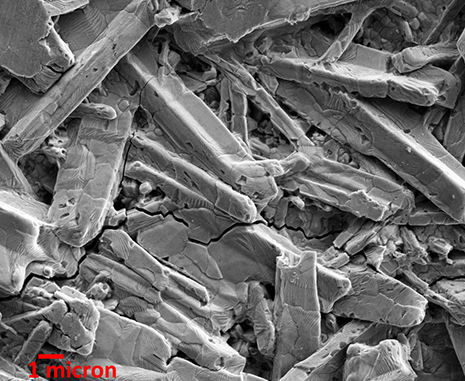

Hot-dip galvanized and electrogalvanized coatings contain uniform chemical composition through the entire coating thickness, unlike galvannealed coatings. Galvannealed surface phases, either delta or zeta, are created by different iron-zinc alloys and feature different characteristics. Compared to zeta-phase surfaces, galvannealed steels with a delta-phase surface exhibit lower friction and contain higher iron levels in the coating. Achieving delta as the surface phase requires the mill to use higher galvannealing temperatures and/or a slower line speed. These conditions promote an increase in powdering, or fracturing within the GA coating at the gamma-delta interface due to compressive or bending stresses. Lower iron content minimizes powdering. All of these conditions and constraints translate into a narrow time/temperature process window in order to achieve a lower friction delta surface with acceptable powdering performance.

Coating Syntax Matters

ASTM A653/A653M provides for coating-weight minimum requirements. The specific per-side minimum requirements are a function of the total coating weight, as listed in ASTM Specification A653.

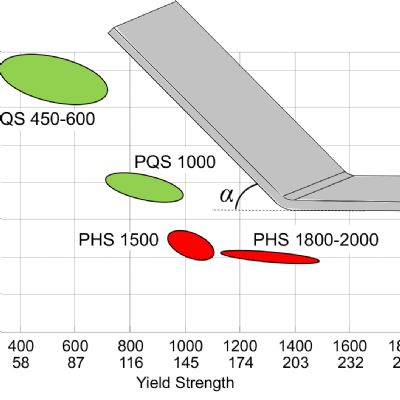

Different metallic coatings can be applied to steel surfaces, with each offering specific characteristics and designated by different letter codes and numbers. With different specifications, the descriptors can differ as well. Hot-dipped galvanized coatings of pure zinc may be abbreviated as GI, HDG or Z. Hot-dipped galvannealed coatings, which contain zinc-iron intermetallics, are abbreviated as GA, HDGA or ZF. Electrogalvanized coatings are shown as EG, EGL or ZE. Other types of coatings used on steel for corrosion protection include an aluminum-silicon (AS or AlSi) alloy commonly found in press hardening applications, and a zinc-aluminum-magnesium (ZAM or ZM) alloy now gaining in applications where cut-edge corrosion is a concern.

As for coating weights, G refers to pure zinc, as in the EG abbreviation for electrogalvanized or GI for hot-dip galvanized. The letter A refers to galvanneal, GA. The number either before or after this letter represents the coating weight. Syntax matters here. For example, the weight of a G60 coating differs from one designated as 60G.

A notation with the number first followed by G or A as a suffix describes the single-side coverage in g/m2. For example, a 60G coating signifies a minimum coverage of 60 grams of galvanized zinc on each square meter on each side of the steel. A notation such as 98G60G indicates a minimum of 98 g/m2 of galvanized zinc on one surface and 60 g/m2 of galvanized zinc on the other surface.

Specifying G40, or any coating where the letter comes first, indicates a minimum total zinc-coating coverage on both sides combined in oz./ft.2 divided by 100. For example, a G40 coating has a minimum total coating coverage of 0.40 oz./ft.2, or an average of 0.20 oz./ft.2 on each side.

Knowing the density of pure zinc, 446 lb./ft.3, allows for the conversion of the coating coverage to a thickness of 0.00034 in. per side, or 8.6 microns per side. Remember that only the total coverage must be 0.40 oz./ft.2, and it is reasonable to assume that each side will not measure exactly 0.20 oz./ft.2. To ensure sufficient corrosion protection, the ASTM A653/653M specification also calls out a minimum single-side measurement as well. For G40, each individual side must measure at least 0.12 oz./ft.2, or slightly more than 5 microns. If this thickness isn’t sufficient for the application, greater coating coverage must be specified.

These differences in syntax mean that a 60G coating measures about the same as a G40 coating. The 60 g/m2 on one side equals 120 g/m2 combined top and bottom, which converts to 0.394 oz./ft.2, about equal to a G40 coating. As another example, a G60 coating weight signifies 0.30 oz./ft.2 of zinc on each surface, which approximates a 90G coating weight.

In Europe, one or two letters (such as Z or ZF representing zinc or a zinc-iron-alloyed coating) followed by a number represents the minimum total coating mass combined on both surfaces expressed in g/m2. Using this notation, Z100 represents a hot-dipped galvanized zinc with a total of 100 g/m2 combined on both surfaces. In practice, the coating weight does not divide exactly evenly between the two surfaces.

Have ideas for topics in future columns? Email me at scienceofforming@eqsgroup.com. MF

See also: Engineering Quality Solutions, Inc., 4M Partners, LLC

Technologies: Materials