Coil-Line Solutions Evolve to Meet Auto Supplier’s Needs

September 5, 2024Comments

Coil and blank processor RSDC, a subsidiary of Marubeni-Itochu Steel Inc., processes as much as 1.2 million tons annually at its 625,000-sq.-ft. facility in Holt, MI. Supplying primarily automotive OEMs, the company maintains an array of capabilities, products and services.

Coil and blank processor RSDC, a subsidiary of Marubeni-Itochu Steel Inc., processes as much as 1.2 million tons annually at its 625,000-sq.-ft. facility in Holt, MI. Supplying primarily automotive OEMs, the company maintains an array of capabilities, products and services.

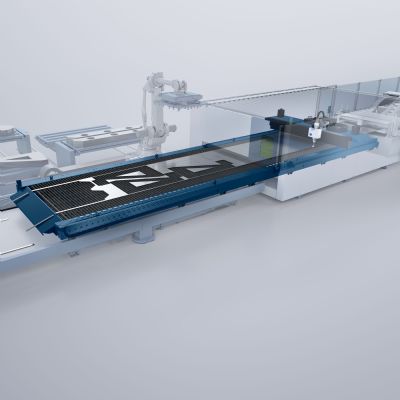

In 2022, RSDC purchased a LaserCoil laser blanking line from Automatic Feed Co., which had been supplying feed equipment to RSDC since RSDC’s founding in 1996. Earlier in 2016, Automatic Feed supplied a LaserCoil blanking line—the first production coil-fed automotive laser blanking line in North America—to RSDC’s sister company, MISA Specialty Processing (MSP), Jackson, MI. Automatic Feed Co. subsequently was acquired by Nidec Corp. in the summer of 2023, and continues to service and upgrade equipment at RSDC and MSP.

“In 1996, when the concept of RSDC was formed, we needed press blankers and a cut-to-length line, and Automatic Feed just happened to be the equipment maker of choice to the customer we were going to be supplying, which at the time was General Motors,” says Christopher VanDeventer, RSDC president and also president of MSP, reflecting on the origins of the partnership. “Every General Motors metal fab facility either had Automatic Feed blankers, cut-to-length lines or both.”

Automatic Feed began installing production machinery at RSDC in 1997, and while those original lines remain in use today, they have been updated throughout the years to reflect the changing technology and market needs.

“The lines were built with progressive technology, meaning that what we bought isn’t what we were stuck with,” VanDeventer says. “The ability for Automatic Feed to improve upon the original design and still incorporate new technology was a key factor.”

Customers of RSDC and MSP are 100% automotive, and the companies strive to keep these customers happy.

“We can slit and blank for them, and inspect,” VanDeventer says. “We perform complete inventory management and scrap management for them, and also take care of 100% of the outbound logistics. Customers sends us the orders and don’t have to worry about anything. We deliver that material when they want it.”

With all of these responsibilities, RSDC relies on flexible, productive processing equipment. The LaserCoil technology provides a case in point on flexibility and productivity, according to VanDeventer.