“We quoted one of our standard press-feed lines, with all of the features and control options included on the Ohio plant’s most recent feed lines,” explains Craig Derosby, marketing manager for Formtek-Maine. “We added powered functions to the quote such as passline height for the servo feed cabinet, edge-guide adjustment, and a roller coil-keeper setting for the stock reel. These features are designed to reduce setup time and make it easier for even newer operators to work on the line.”

Because the company sought to maximize automation, Formtek-Maine suggested that it set up the powered features automatically to further expedite setup times. “We wanted a system where the operator could call up a job for a specific part and everything would move into position,” Stockman says. That would free up the operator to concentrate on other tasks such as loading the coil or threading the line.

Customizing the System

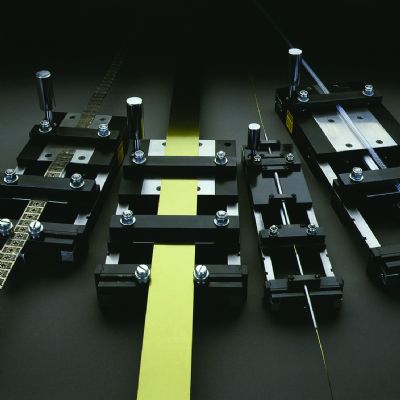

The company decided on installing three nearly identical, 36-in.-wide servo-driven press-feed lines, paired with new Komatsu two-point H2W 200-H (high-speed) servo presses. Each feed line comprises a 20,000-lb.-capacity uncoiler with accompanying coil car, a powered straightener with a hold-down peeler station on the entry end to facilitate hands-free threading and a Unist stock-lubrication system.

The company decided on installing three nearly identical, 36-in.-wide servo-driven press-feed lines, paired with new Komatsu two-point H2W 200-H (high-speed) servo presses. Each feed line comprises a 20,000-lb.-capacity uncoiler with accompanying coil car, a powered straightener with a hold-down peeler station on the entry end to facilitate hands-free threading and a Unist stock-lubrication system.

The two-roll servo feed lines were engineered for maximum automation with Allen/Bradley Kinetix controls and Compact Logix PLC—a “total system control,” according to Formtek-Maine officials. The system positions a color touchscreen HMI at the feeder control console and a second touchscreen at the straightener control panel to control the back of the line: the straightener, hold-down peeler station, threading tables, uncoiler, and coil car. With this control, an operator can thread a coil in 5 min. and set up the entire feed line in less than 1 min.

|

|

|

|

The Formtek-Maine ServoMax feed-control program allows operators to set all powered features of the line automatically upon recall of a job number. It has storage capacity for as many as 200 jobs, detailing the standard values of length, batch size, and speed settings from 1 to 10, as well as additional settings for coil width, coil OD, material thickness and passline height.

The powered feed cabinet adjusts to the correct passline height. Edge guides at the feeder and straightener and the roller coil keepers on the uncoiler traverse to match the coil’s pre-programmed width. Upper straightener rolls move to the correct positions to straighten the material thickness stored under that job number. A barcode scanner can be used to scan barcodes on the labels of incoming coils and call up the job associated with that coil barcode.

![C_BA21-1188_ProdPho_RI_Prod_BeamHanger_C0[55]](https://www.metalformingmagazine.com/public/images/2025/04/C_BA21-1188_ProdPho_RI_Prod_BeamHanger_C0.jpg) The straightener touchscreen includes a host of on-screen functions. Digital roll-position readouts for the upper straightener-roll settings facilitate threadup of a new coil. Diagnostic fault messages with recommended remedies automatically appear on screen to warn the operator of an error and how to correct the problem.

The straightener touchscreen includes a host of on-screen functions. Digital roll-position readouts for the upper straightener-roll settings facilitate threadup of a new coil. Diagnostic fault messages with recommended remedies automatically appear on screen to warn the operator of an error and how to correct the problem.

The operator has access to on-screen step-by-step threadup instructions with illustrations, enabling new operators unfamiliar with the equipment to thread the line easily. Maintenance screens with diagrams facilitate troubleshooting and include manual lubrication points highlighted for ease of maintenance. The timers for the automatic lubrication pumps can be set on the screen as well. And, on-screen parts diagrams for each machine, the hydraulic and pneumatic schematics, and the electrical prints provide part numbers for each item for quick and easy part identification in a breakdown situation.

As a fail-safe measure, the controls supplement the touchscreen virtual buttons with real-world hard buttons and switches. In the event that a touchscreen fails, a metalformer can still operate the line while a new HMI is procured and programmed.

As a fail-safe measure, the controls supplement the touchscreen virtual buttons with real-world hard buttons and switches. In the event that a touchscreen fails, a metalformer can still operate the line while a new HMI is procured and programmed.

Result: Safer, Faster

“The new features have helped us eliminate safety issues that we had previously experienced,” Stockman relays. “The automated coil keepers mounted onto the mandrel have eliminated the need for operators or setup technicians to handle coil keepers manually, thus reducing the time they spend during a coil changes.

“Also, having all of our jobs preprogrammed into the system has helped quicken setup times,” he adds. “When the setup technician selects the next job, all the guides move to a preprogrammed spot and the feeder self-adjusts to the right height for the new job. This has helped us tremendously with coil and job changes.”

Due to faster setup times, production runs can start sooner, which has increased production, though speeding throughput was not the main goal, Stockman concludes. “As the new presses and equipment we bought have the same tonnage and specs,” he says, “we were not looking into accelerating production as much as we were looking into eliminating security risks and easing setups.”

How did the new press equipment enhance security? “The outdated PLC that controls the line put us at risk for cybersecurity attacks. The new updated version of the PLC has security features built in that mitigate that risk,” Stockman adds.

Continuing Updates

Derosby says that the lines have been working so well that Simpson Strong-Tie ordered a fourth, 72-in.-wide, 30,000-lb.-capacity ServoMax H8-series high-capacity servo-driven coil-feed line, installed last September. It is currently in full production.

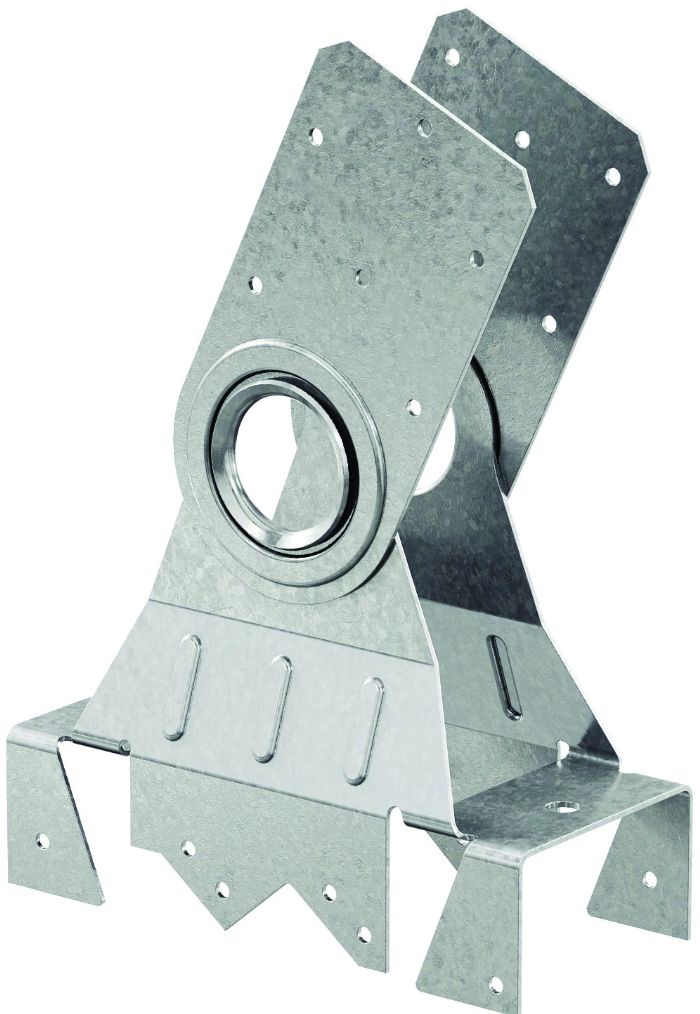

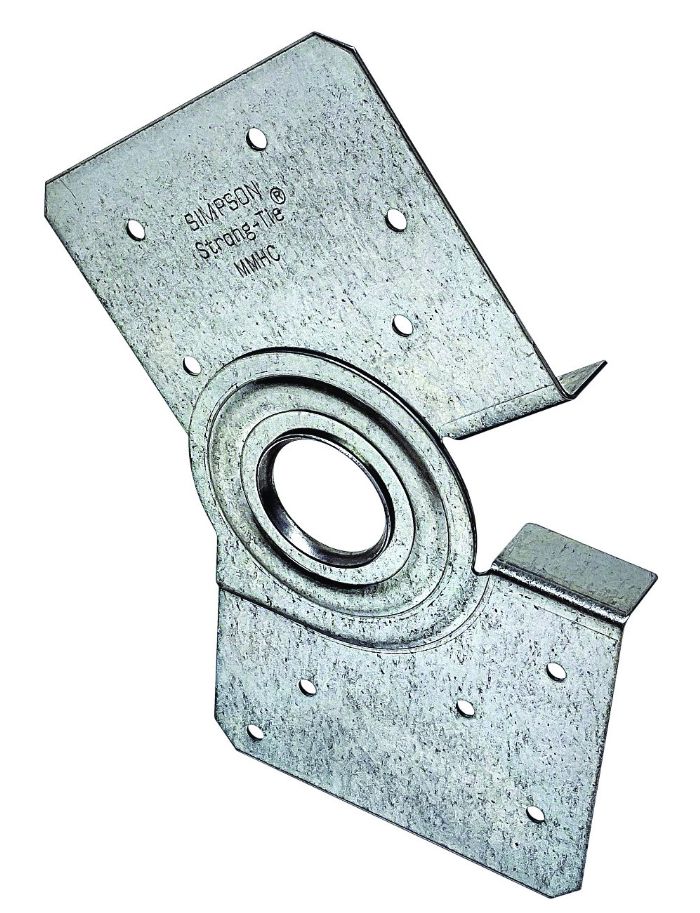

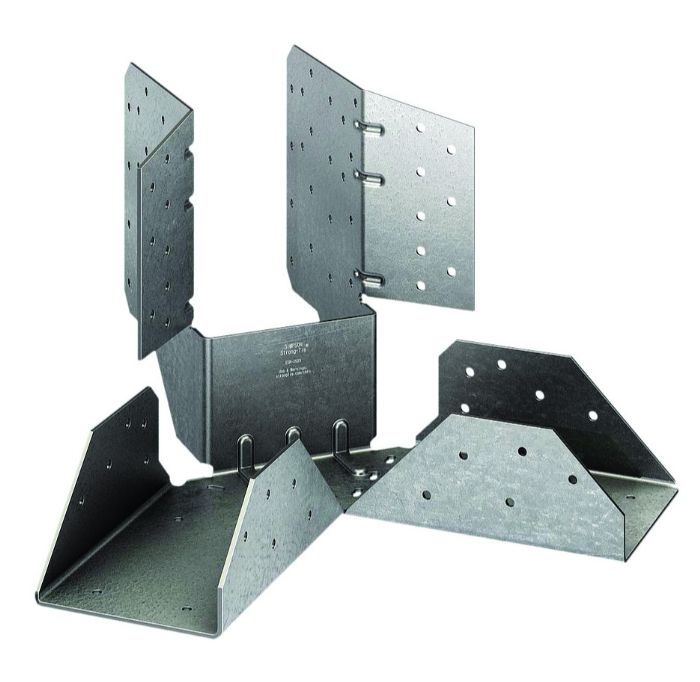

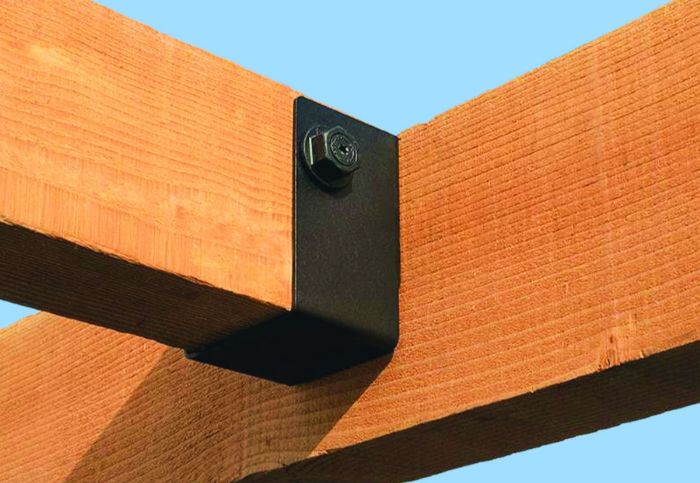

“The widest coil that we stamp is 60 in., and it produces the MST60, which is an 60 in. flat strap,” Stockman says. “We also produce our BA (beam hanger) line of hangers on that line.” MF

View Glossary of Metalforming Terms

See also: Formtek-ME, Komatsu America Industries, LLC Press Technology Division

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingDallas Industries Delivers Another Feed Line to Manitowoc To...

August 28, 2024

Coil and Sheet Handling

Coil and Sheet HandlingPress-Feed Equipment

Tuesday, June 17, 2025

Coil and Sheet Handling

Coil and Sheet Handling5 Questions About Air Feeds; 5 About Servo Feeds

Bradley Nordlof Thursday, April 17, 2025

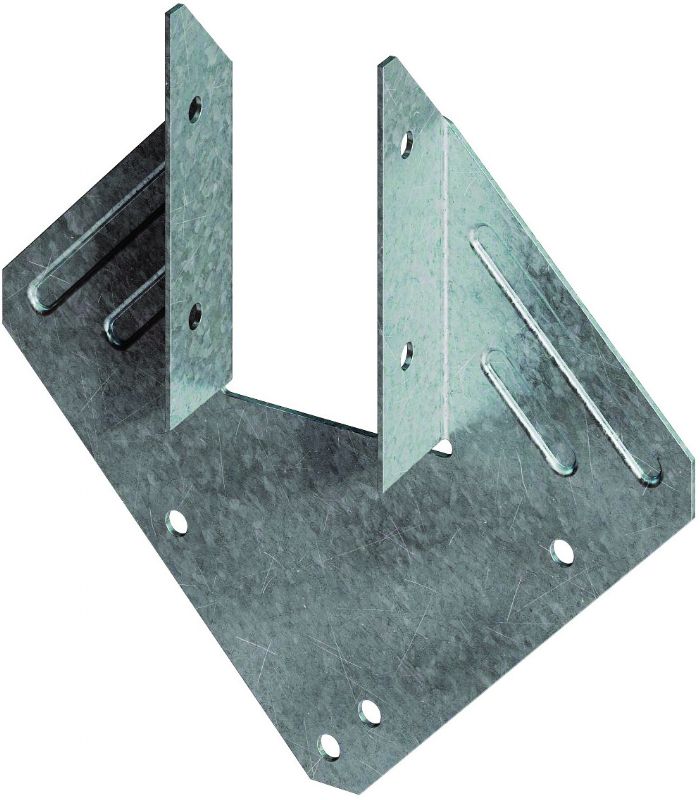

Its connectors, hardware, fasteners and fastening systems, hangers, hold-downs and hurricane ties, and other metal components and assemblies hold fence sections to posts, deck boards to joists, roofs to beams, and columns to timbers, and similar tasks. It’s imperative that these products be strong and code-adherent.

Its connectors, hardware, fasteners and fastening systems, hangers, hold-downs and hurricane ties, and other metal components and assemblies hold fence sections to posts, deck boards to joists, roofs to beams, and columns to timbers, and similar tasks. It’s imperative that these products be strong and code-adherent. Widely considered the gold standard in the building-connectors sector, Simpson Strong-Tie depends on state-of-the art production equipment and machinery to produce its quality products. Manufacturing in an industry segment with a heightened awareness of safety and security, the company is keenly aware of the need to operate safely and securely.

Widely considered the gold standard in the building-connectors sector, Simpson Strong-Tie depends on state-of-the art production equipment and machinery to produce its quality products. Manufacturing in an industry segment with a heightened awareness of safety and security, the company is keenly aware of the need to operate safely and securely.  “We had a company audit our equipment to see what was outdated and obsolete,” says Chris Stockman, manager of manufacturing operations. “We needed to upgrade a lot of our legacy equipment, as well as our software.” Stockman also wanted to update the equipment’s security. “There weren’t any problems, per se, but the equipment’s current unsecured condition could pose a security risk if left unaddressed,” he says.

“We had a company audit our equipment to see what was outdated and obsolete,” says Chris Stockman, manager of manufacturing operations. “We needed to upgrade a lot of our legacy equipment, as well as our software.” Stockman also wanted to update the equipment’s security. “There weren’t any problems, per se, but the equipment’s current unsecured condition could pose a security risk if left unaddressed,” he says.