Sophisticated Internal Passageways

For metal parts requiring sophisticated internal-channel geometries, whether with an inlet and outlet—or neither—there can be many twists and turns. Examples include heat-exchanger applications that require shops to machine channels into aluminum to disperse heat by air or liquid cooling. Given that the surface area of the cooling zone is a primary factor in heat transfer, the more extensive the channels, the better.

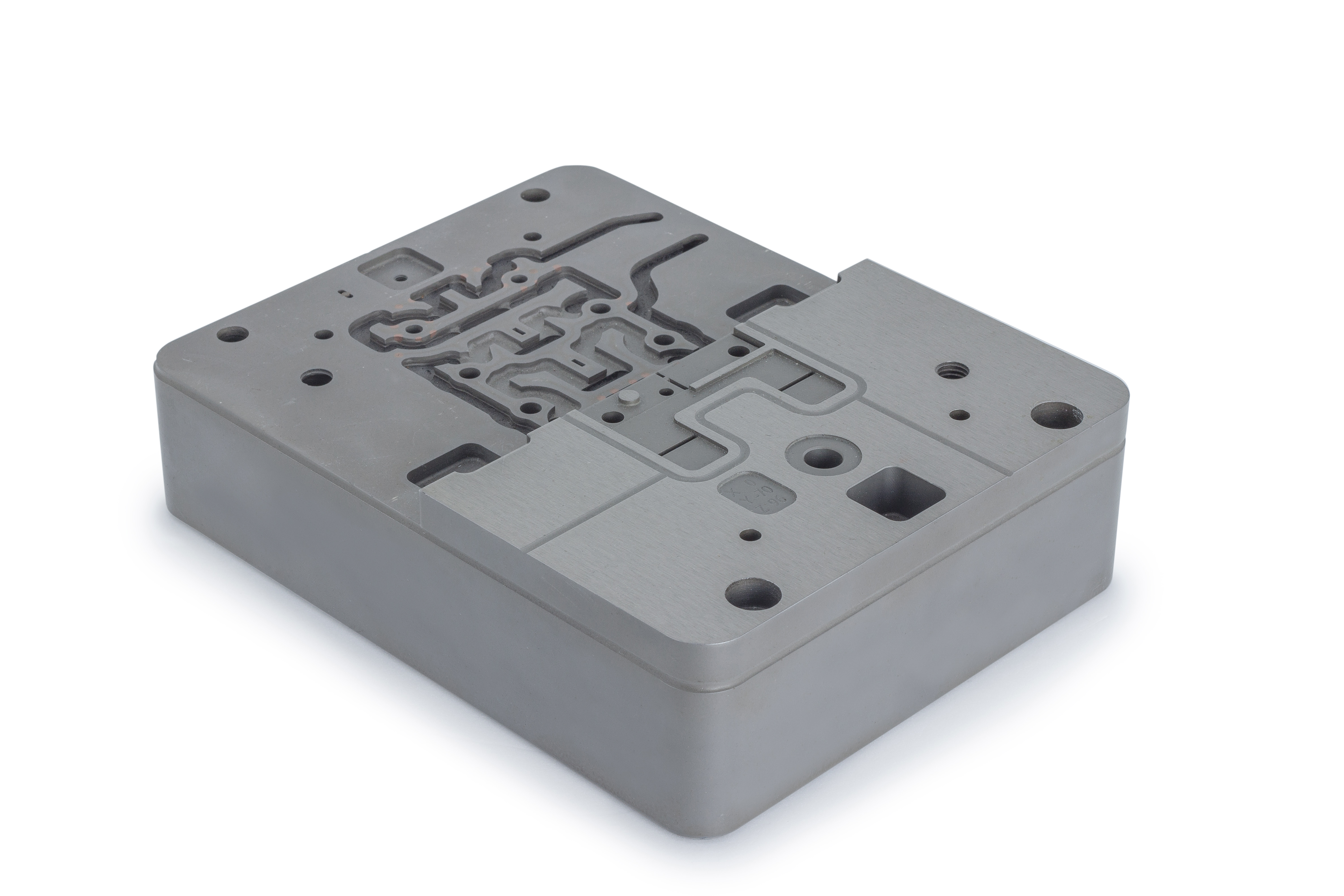

LOM also can fabricate plastic injection molds with conformal-cooling channels, which in turn will improve process efficiency and cycle times. These cooling passageways follow the shape or profile of the mold core or cavity to perform a rapid, uniform cooling process during injection and blow molding.

There also are applications with liquid and gas dispensing equipment. In semiconductor and microelectronics fabrication, for example, sophisticated “showerhead-style” gas-distribution assemblies will dispense processing gases into a semiconductor etching and deposition chambers. These dispensing heads often have multiple, separate internal passageways readily created with the LOM process.

Bonding Layers of Metals and Alloys

Given that traditional CNC cutting tools typically cannot adequately machine the types of passageways described above, one alternative—already used for items such as showerhead assemblies—is an additive process that joins thin sheetmetal layers using brazing material.

Although brazing can join similar and dissimilar metal alloys with considerable strength, it also has significant drawbacks on parts with internal passageways. Brazing can cause small fillets to form in the passageways, which can obstruct flow and even break off during use. Too little brazing material can create voids where liquid or gas accumulates and corrosion sets in, particularly in the presence of harsh chemicals such as those used in the semiconductor industry. This can lead to delamination of the layers and premature replacement of what can be extremely expensive parts fabricated from exotic materials.

Diffusion bonding, on the other hand, creates a superior bond without the need for filler material. During diffusion bonding, high temperature and pressure applied to the workpieces cause the atoms on solid metallic surfaces to intersperse and bond. Unlike traditional brazing techniques, the resulting bond exhibits the strength and temperature resistance of the base materials.

For the atoms of two solid, metallic surfaces to intersperse, they typically must be at 50 to 70 percent of their absolute melting temperature. To achieve these temperatures, the workpiece surfaces are heated—either in a furnace or by electrical resistance—to temperatures as high as 1400 C.

Shops have employed this technique for many years to join high-strength and refractory metals that prove difficult or impossible to weld by other means. However, recent improvements in diffusion-bonding presses have made the process even more attractive. For example, new multi-cylinder hydraulic presses boast improved capabilities over single-cylinder presses that require fixtures to apply a consistent, measurable amount of force—a key factor in the process.

By independently controlling each cylinder, a multi-cylinder press can provide extremely consistent pressure across the entire surface of the workpiece. In some cases, built-in pressure transducers along the bottom of the pressing plate allow for the adjustment of individual hydraulic cylinders, resulting in precise pressure uniformity over large areas.

Case in Point

According to Walt Roloson, R&D engineering manager at PVA TePla, a German manufacturer of multi-cylinder hydraulic presses for diffusion bonding (with U.S. offices in Corona, CA), one of the most appealing aspects of the process is its ability not only to create internal structures, but also to join layers of dissimilar metal alloys.

“Customers often seek to bond aluminum to molybdenum or stainless steel,” says Roloson, “which we can do with diffusion bonding.”

Multi-layer bonding also improves conformal-cooling performance in plastic injection molds manufactured in two-layer designs combining tool steel with a stainless-steel mold steel (Uddeholm Stavax ESR, for example).

“For the most efficient performance, shops should adapt conformal-cooling channels as precisely as possible to the outer shape of the mold,” says Roloson. “The greater the number of bonded layers, the more precisely a channel can match the outer shape.”

By improving cooling performance, melted resins can be injected at higher pressures to significantly increase cycle times—by as much as 40 percent—while enhancing product quality.

With the layers diffusion bonded together, Roloson says that shops then can use traditional machining techniques to create the final external shape.

“Due to the molecular bonding of the layers, the final part often shows no interface lines or striations,” he adds. “The interface of one material actually is blended into the other one, and vice versa, even with dissimilar materials.”

Although the LOM process appears ideal only for specialized applications, precision machine shops may find that it’s the perfect complement to inhouse laser-cutting and machining capabilities. 3DMP

Article provided by PVA TePla America: 951/371-2500, www.pvateplaamerica.com.

Industry-Related Terms: Alloys,

CNC (Computer Numerical Control),

Core,

Delamination,

Etching,

Form,

LASER,

Layer,

Lines,

Plate,

Resins,

Stainless Steel,

Surface,

TransferView Glossary of Metalforming Terms

See also: PVA Tepla America

Technologies: