The machine was ordered in December 2017 and installed in February 2018, when a Mazak service technician spent two weeks overseeing installation and startup. A senior installation technician followed, spending an additional week to ensure that the equipment ran smoothly.

This level of customer service and the system’s features proved a winning combination for Southern Design. “We really liked the CNC control and the interface,” says Tance. “It’s easy to use and has more data that show what currently is being processed on the machine. We also like the material-handling features. The workpiece lifters (roller-ball transfer devices) make it easy to position material while the shuttle table (an automated two-pallet changer design) allows for easy in/out of material and cut pieces. While one sheet is being processed, finished parts are pulled off. This, and the increased speed of the laser—about 15 to 20 percent faster than our first laser—improves throughput.”

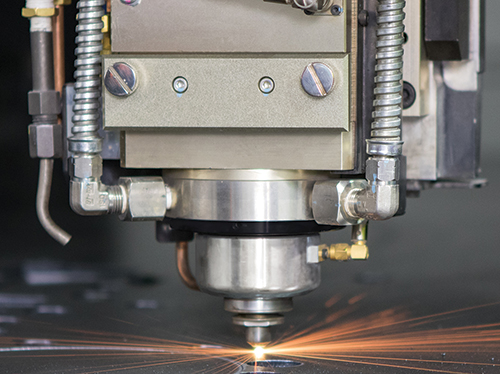

|

| An automated two-pallet-changer design allows for easy in/out of material and cut pieces. |

- Automatic nozzle changing;

- Automatic nozzle cleaning;

- Automatic profiler calibration;

- Focus detection;

- Automatic focus positioning;

- Pierce detection;

- Burn detection; and

- Plasma detection.

“The automated processes result in less downtime and greater machine realiability, which means we’re able to get more products out the door faster,” says Tance.

Overcoming Challenges

While Southern Design wasn’t Mazak’s first home-décor customer, its volume of business and its products presented a challenge in terms of software programming, says David Widlund, Southwest regional sales manager for Mazak.

|

| Shown here are the operator control unit at rear of machine and full-side sliding door to access the cutting area. |

In addition to its features, the 37 by 20-ft. machine is designed for flexibility upon installation, according to Widlund. “When we had to move the chiller on the machine due to Southern Design’s space constraints and its building design, this wasn’t a problem because of our plug-and-play versatility,” he says. “The periphery equipment—the generator, chiller and dust collector—all have extended cables so that they can be moved as far as 15 ft. to accommodate building requirements. These items can be extended even further away if need be by purchasing extended cables.”

“With Southern Design’s volume continuing to rise, it’s likely that so, too, will its equipment needs,” says Tance. “We are considering adding a third laser in 2019.” MF

View Glossary of Metalforming Terms

See also: Mazak Optonics Corporation

Technologies: Cutting