Other than Cutting Speed, What Else Matters?

We posed that question to Rivera, who—as expected—had no problem coming up with an answer.

“Edge quality is critical to our applications,” says Rivera, noting that the firm cuts everything except for very thick work with nitrogen, to enhance adherence of the powder coating.

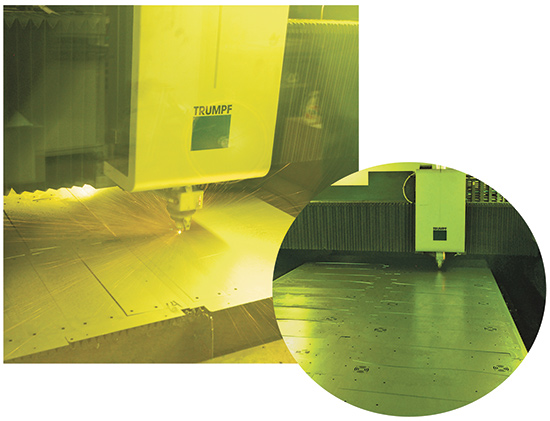

“Also, our POP displays must be attractive to consumers,“ Rivera adds, “so as we looked to invest in this newest Trumpf cutting machine, cut-edge condition became a critical requirement.”

Enter Trumpf’s BrightLine technology, developed to enable the cutting of thicker material with the solid-state process, typically reserved for thinner sheetmetal. For example, while the TruLaser 5030 solid-state system previously was rated for cutting 20-mm stainless steel and 25-mm mild steel, the machine could not process higher-strength materials at the same level of quality that a CO2 laser could. Fabricators might wind up with uneven cut surfaces and edge burrs. BrightLine—new technology that according to Trumpf literature accelerates the cutting gas to a high velocity, and provides customized process parameters—eliminates those concerns. Rivera concurs.

“In mid-2013, we landed a job to fabricate POP displays for an automaker, requiring us to cut 5⁄8-in. steel plate,” Rivera explains. “When we cut the material on Sabine (the 3-kW solid-state machine), the customer accepted the parts. However, we felt that edge quality could have been better. When the job came back to us earlier this year, we ran it on Helena (the 5-kW machine with BrightLine technology) and we saw a huge improvement in edge quality. And, the job ran at a faster cutting speed. We’ve seen this type of quality improvement across the board—no discernable burring or slag, and minimal surface roughness on the cut edges.”

What About the Narrow Kerf from Solid-State Cutting?

Rivera offers a good answer to this question, as well—one that often comes up when discussing and comparing solid-state laser cutting (using either fiber lasers or Trumpf’s TruDisk solid-state technology) with CO2 laser cutting. Bottom line: the narrower kerf from the solid-state laser beam can impede cutting of thicker material, including making it difficult to extract cut parts from the skeleton. Not so with the BrightLine feature, says Rivera.

“We cut ¾-in. steel for our plow customers, large pieces 2 ft. long with a very contoured edge,” he explains. “If we tried to do this on Sabine, the narrow kerf would make it difficult if not impossible to extract the cut parts. Running the job on Helena, the wider kerf we can develop with BrightLine technology allows us to extract the parts using an overhead magnetic manipulator.” MFView Glossary of Metalforming Terms

See also: TRUMPF Inc.

Technologies: Cutting