Servo-Electric Punch Press to the Rescue

The new servo-motor-driven turret press, from Murata Machinery USA, Charlotte, NC, is a Motorum-2044EZ model. It features a 50 by 50-in. table with a 22-station turret, and a 20-ton electric punch drive that, according to Murata Machinery representatives, provides all of the advantages of hydraulics without the mess. It boasts what is reportedly the industry’s first servo-motor-controlled ram drive, and was designed specifically to be the “extra machine” needed to take the load off of over-burdened lasers and serve as a prototype and low-volume machine for stamping houses such as S&S.

In the six months or so that S&S has been operating the new turret press, it’s been able to book enough work to run the press at about a 60 percent uptime.

“This is work we would have lost to a fabricator,” says Sprinkle, “because the part runs are too low for stamping. We found we were beginning to become just a metal finisher on some work, where fabricators were sending us punched and formed parts. So we had just a piece of the pie. Now, thanks to the turret press, we have the whole pie.”

Asked to delineate how work routes to either stamping or fabrication operations, Sprinkle explains that any jobs requiring more than 50,000 pieces/yr. would likely be hard-tooled. The turret press, so far, has been running smaller parts such as brackets for appliance control panels at volumes in the neighborhood of 1000/month. Sprinkle has programmed about 20 different parts for the turret press.

“I do all of the programming, including nesting parts on the 4 by 8-ft. (typically 0.048-in.-thick) sheetmetal blanks,” he says. To run a nested sheet, the machine operator on the plant floor simply enters the nest number into the CNC and loads a sheet onto the press bed. He runs one part and takes it to quality control for a dimensional check, then, with approval, goes ahead and runs the lot. Punched parts route to a hydraulic 8-ft. Cincinnati CNC press brake for forming.

Becoming Programming Proficient

“No one here had ever programmed or operated a turret press,” says Sprinkle, asked to describe any specific challenges to getting the new press up and running, “but thanks to the ease of programming (of both the nesting software, SigmaNest from SigmaTek Systems, Cincinnati, OH, and the machine’s CNC) we were able to get up and running in one month after installing the machine.

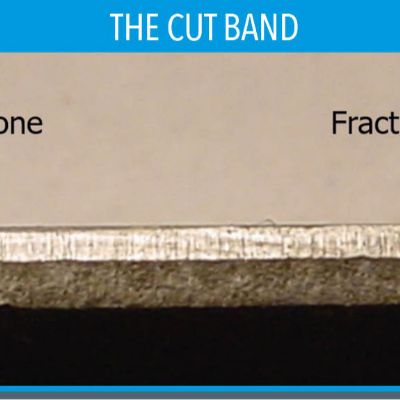

“The parts we’re making on the turret press can be quite complex, requiring frequent tool changes by the turret,” continues Sprinkle. “Many parts require 12 different punch tools, making holes in diameters from 0.094 to 2-plus in. Many parts also require very minute detailing—radiuses and angles. And while we’re not doing any forming yet with the press, we’re quoting a large oven-panel job that will require the press to form gusset beads.

“There are all kinds of opportunities for us to do more with this machine,” Sprinkle continues, including working to develop more efficient sheet nests and tweak blank sizes to improve on material utilization. He also is working to program his nests so that during punching and nibbling operations, the parts will be more securely held in the sheet, and then broken out of the sheet by the operator at the end of the run.

“There are some nests we run that require us to slow the press down to prevent the parts from being shaken out. I need to go back and tweak the programming so that we can run faster,” Sprinkle says.

With his two-year return-on-investment goal seemingly within easy reach, Sprinkle adds, “I’m very pleased with the press and how easy it has been for us to get up and running so quickly, and to bring in so much work for it in such a short time. I hope to purchase a second turret press later this summer.” MF

View Glossary of Metalforming Terms

See also: Muratec Murata Machinery USA, Inc., CAMBRIO/Sigmatek Systems, LLC

Technologies: Stamping Presses