More Press Energy

December 1, 2008Comments

In the September issue of MetalForming, Tooling by Design addressed important distinctions between press tonnage and press energy for mechanical press systems. Based on recent requests and questions posed at seminars, further discussion seems appropriate, particularly from a practical application perspective.

The tonnage rating of a press is the maximum load that can be exerted in continuous operation without causing damage to the machine structure or its drive system. The tonnage rating of a mechanical press usually is determined at a slide (ram) position somewhere between 1⁄32 and 1⁄4 in. above bottom-dead-center (ABDC), depending on machine design and the manufacturer. The available working force decreases in mechanical presses as the ABDC distance increases. This occurs because the lever-arm angle—the relationship between the crankshaft angle and the pitman—has reduced mechanical advantage higher up in the stroke.

The main motor, along with its electrical connections, is the only source of energy for the press and it must have sufficient horsepower to supply the demands of the stamping operation. The press flywheel, by virtue of its mass and rotational speed, is the energy storage device. Flywheel energy is expressed in in.-tons of torque. In combination, the flywheel stores and delivers the required work energy while the electrical motor restores energy by maintaining flywheel speed and avoiding excessive slowdown.

Deep-drawing operations consume large amounts of press energy due to their

|

| Fi |

long working distances, sometimes beginning several inches ABDC. For example, pushing 200 tons through 2-in. of deep drawing requires 400 in.-tons of energy, while a 3-in. draw requires 600 in.-tons. Changing the part material to higher-strength steel could require 500 tons of force working through the same 3-in. distance; thus, expending 1500 in.-tons of energy.

The questions asked most often are, “How do I calculate energy requirements?” and “How would I use this information?”

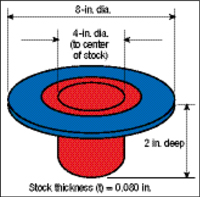

Consider the deep-drawn cup in Fig. 1. The cup is produced in a single-station blank-and-draw operation. The blank material is mild steel with 35,000-psi shear strength (Ss) and 56,000-psi tensile strength (Ts). The blank thickness (t) is 0.080 in. In this example, the process was quoted to run in a machine no larger than 150 tons. Does a 150-ton press have enough energy to run this die?

First, calculate the tonnage required to produce the blank and cup using the following formulas:

|

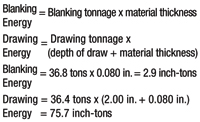

Now calculate the energy requirements using the following formula:

|

We could move the process to a larger press with more energy capacity. But this may require a 300- or 400-ton machine with a higher operating cost than the one assigned when the job was quoted. But a savvy engineer, with properly calculated energy requirements, can evaluate other machines within the plant based on their energy capacities. As it turns out, this company has a 110-ton, single-geared, standard-speed machine with an energy rating of 130-in. tons at 40 strokes/min. This machine meets both the energy and tonnage requirements for the job.

Can a lesser-tonnage machine provide more energy—even at slower speeds? Yes. I’ll explain why next month. MF

View Glossary of Metalforming Terms

Technologies: Quality Control, Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Quality Control

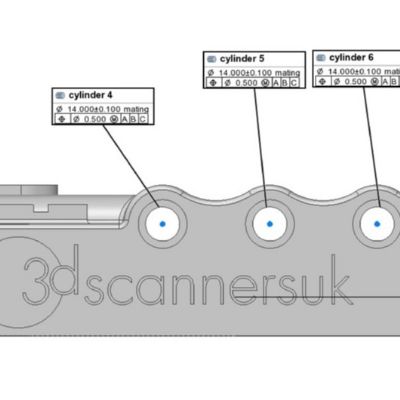

Quality ControlOnline GD&T Training

Tuesday, October 29, 2024

Use Lean Six Sigma for Efficiency & Quality Improvement

Daniel Schaeffler Friday, October 27, 2023

Management

ManagementSeeking Small Victories: Continuous Process Improvement

Daniel Schaeffler Monday, September 25, 2023

Quality Control

Quality ControlAn Introduction to Quality Management Systems

Daniel Schaeffler Thursday, July 27, 2023