Myriad Options

|

| Shown here, one of the complex parts RPM Design produces on its waterjet-cutting machine. |

It is difficult to name a material RPM Design does not handle. “I’ve cut felt, wood, cardboard, plastic, phenolic plastic, fiberboard, fiberglass, brass, copper, steel, aluminum, stainless, Inconel and even bulletproof glass,” Price says. “We also have cut Jabroc, a compressed wood used in racecar skid plates.”

In addition, Price says that multiple layers of different materials do not faze a waterjet. For example, RPM Design cuts multilayered steel head gaskets consisting of two or more thin layers of steel sandwiched with sealing material to form a highly pressure-resistant seal for extreme-pressure applications. In fact, the tooling cost for waterjets, according to Price, is about the same regardless of the material being cut.

“Cutter life doesn’t shorten because you’re cutting carbon fiber like it does with conventional machining,” Price explains. “Consumables costs are much lower with waterjets as compared with conventional machining.”

Price also practices nesting strategies in which he programs multiple parts on a single sheet or plate of material, maximizing material utilization and minimizing setup time for different parts. About 80 percent of his work involves nesting—a simple process to learn, he reports. “We set up the machine and the Omax representative spent a couple of days here,” says Price. “In a few hours we were off and running, cutting parts.”

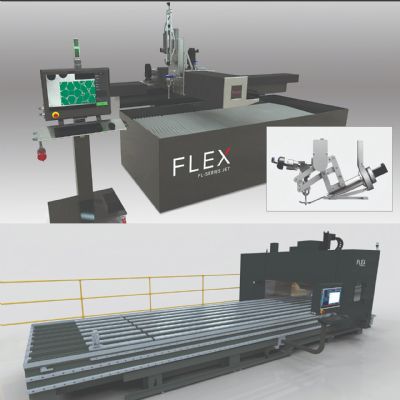

To further ease the waterjet-cutting process and increase productivity, Omax offers a selection of options. For RPM Design, that meant adding an A-Jet multiaxis cutting head to its Maxiem. The head provides 0 to 60-deg.-angle cutting range and facilitates the machining of beveled edges, angled sides and countersinks. Intelli-Max Software from Omax even enables the A-Jet head to compensate for the natural taper of a waterjet stream, allowing for creation of complex 3D shapes.

|

| A multiaxis cutting head allows RPM Design to cut angles ranging from 0 to 60 deg. as well as create beveled edges, angled sides and countersinks. |

The A-Jet head offers high positioning accuracy, reportedly resulting in cut parts that require no secondary finishing, thus reducing part-production time. “I selected the A-Jet to cut angles as well as for taper control,” Price says. The head, calibrated within 0.0015 in., allows him to cut complex parts such as vehicle exhaust header flanges.

Price, who has made parts for winning vehicles in nearly all motorsports, singles out a particularly memorable job. “Two years ago, parts that I produced here were on the pole-sitting car for the Indy 500.”

One-day Turnaround

Generally, the RPM Design shop schedule is booked for a week or a week-and-a-half in advance. “Depending on the run time of a job and the scheduling, jobs usually are completed in a day,” Price says. He notes that he may complete 10 or 15 jobs per day, with some jobs consisting of 10 to 20 pieces, while others can range from 1500 to 3000 pieces. Currently, 30 to 35 percent of RPM’s work is repeat business, with the number of new customers increasing.

As a one-man shop, balancing the shop’s work schedule is Price’s biggest challenge. “Managing work flow is the same as in any job-shop situation,” he says. “You get a job one day with a 4- or 5-hr. cycle time, then you get a job the next day with five different materials and you’re running different piece parts.” On days with longer runs, he does programming, invoicing and prep work.

The accuracy and reliability of the Maxiem machine, says Price, enables continuous, uninterrupted operation, “I put a 4 by 8-ft. or 5 by 10-ft. piece of material in the machine in the morning and let it cut all day,” he says.

“With job size and complexity at RPM ranging from multi-thousand-piece runs for industrial companies to small runs for a signage company, the thing that blows my mind every day is the versatility of the waterjet,” Price continues. “I even cut tiny wrenches out of stainless steel for an artist that polishes them to make bracelets and rings. The gamut of jobs coming through here amazes me on a daily basis.”

MFArticle submitted by Omax Corp., Kent, WA; www.omax.com.

View Glossary of Metalforming Terms

See also: Omax Corporation

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingOmax Launches Mobile Ordering Application

Thursday, June 20, 2024