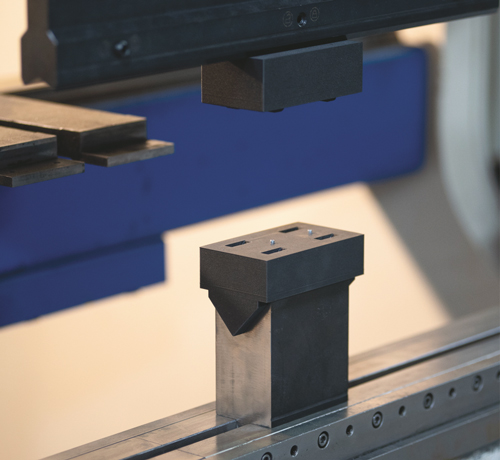

So he and the Centerline team suggested a 3D-printed punch and die, but the customer believed that AM tools would not form its parts.

Centerline set about printing the punch and die via the Mark Two, using Markforged’s Onyx composite material, which boasts 1.4 times the strength and stiffness of ABS plastic material, according to company officials. In producing the tools, Centerline personnel paused printing midway through to reinforce critical points with steel inserts, then continued. The resulting tools provided a pleasant surprise for the customer, as, backed with the steel-reinforced forming features, they easily shaped a laser-cut sheetmetal blank. The tooling cost less than $200 to print, according to Centerline officials, representing an 86-percent reduction in costs for the customer as compared to a conventionally manufactured tools. Not only that, the quick print work reduced project lead time by 88 percent.

Now Ingrained in Company Culture

The press-brake-tool case study showcases AM capabilities available to metalformers and fabricators, and Centerline has made it a point to extend the technology’s benefits.

The company has printed everything from fixtures for inspection, welding and assembly to custom tooling and end-use parts shipped out to larger clients. That’s a far cry from Vickery’s initial interest in 3D printing, when he thought the technology only would work for prototyping. These days, the company’s workflow now includes consideration of 3D-printed fixtures and tooling on many of its manufacturing projects.

Centerline engineers and machinists were skeptical early on, as well. Once Vickery proved that he could make strong parts at a fraction of the cost, his team quickly got on board. Since then, he reports regularly being approached by team members with ideas for parts and tools to be printed instead of machined.

“We're looking for tools and fixtures that help us to be more precise and efficient,” Vickery says. “Now we can take a CAD drawing, print it out and say, ‘Here’s the fixture’ within half of the time it used to take to produce using traditional methods. And, (with plastic and reinforced nonmetal materials) we’re getting close to the strength of aluminum in the pieces we make. The material is much stronger than I had ever expected, and it holds up over time.” MF

Information for this article provided by Markforged, Watertown, MA; 866/496-1805.

View Glossary of Metalforming Terms

Technologies: Additive Manufacturing, Bending