The company recently added new punching capabilities, and will soon add a new press brake to its lineup—an Accurpress model selected in part because of its seamless integration with Radan.

“One of the reasons I went with Accurpress is because it has had success with the Radan offline-programming software for its press-brake controls,” Powers says.

ERP Generates Job Routers

Jobs begin at QFS when operators enter purchase orders into the company’s ERP system, which in turn generates a router, or job traveler, with vital job information. The plant manager then generates a daily manufacturing schedule based on due dates and hands it off to the company’s CNC programmers.

QFS sometimes receives customer designs in the form of solid models, which easily import into Radan with geometry intact. Other customers supply designs on paper, which QFS programmers redraw in Radan using the software’s CAD capabilities.QFS programmers generate nests whenever possible, which reduces material costs and manufacturing time. To ensure ideal results, Radan analyzes part shapes, materials and thicknesses for components to be nested on sheets, off-cuts or remnants. The system’s nest-editing tools provide an additional level of flexibility to users wishing to edit automatically generated nests. Radan also produces associated data so that shop-floor personnel quickly and easily can identify completed parts.

“We may have the parts of three different customers on one sheet,” Powers says, “and we have a printout generated by Radan that helps us match the parts with the prints. It shows how they’re nested, and tells us the quantity.”

An Estimation Tool as Well

Powers, who oversees all sales for QFS, also uses Radan as an estimation tool, as he can quickly determine accurate job costs based on the software’s ability to identify material needs. “Nesting occurs quickly,” Powers says, “and I do all of the quoting, so it’s nice that I can quickly determine what the material utilization will be for each job. I use the software not just to program, but also to help create my quotes.”

With customer service at the forefront of his activities, Powers notes that Radan’s nesting capabilities are an asset to be shared with his existing customers, as well as a money-saving bonus that he can use to grow his customer base.“The ability to nest parts allows us to save our customers money, and I typically pass on all of those savings on to the customers,” Powers says.

Most significantly, the integration of Radan has helped the shop increase efficiency, set and enforce standards, and instill a high level of overall consistency. That type of customer service is second nature to Powers, who is enjoying the fruits of his efforts. While QFS earned more than $400,000 in sales in 2014, the company’s coffers grew to more than $600,000 in 2015 and to more than $1 million in 2016. In other words, the investment in process improvement is paying for itself. MF

Article provided by Vero Software; www.verosoftware.com.

View Glossary of Metalforming Terms

See also: Radan CIM Inc.

Technologies: Bending, CNC Punching, Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Software

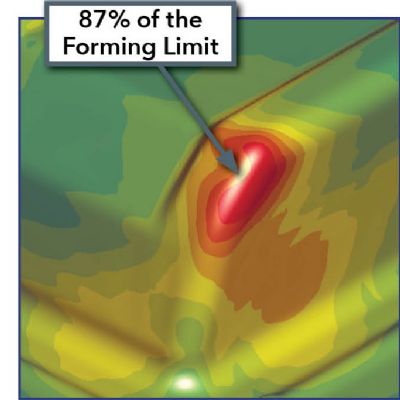

SoftwareSimulation Software Elevates Die-Development Efficiency

Brad Kuvin Tuesday, June 10, 2025

Materials

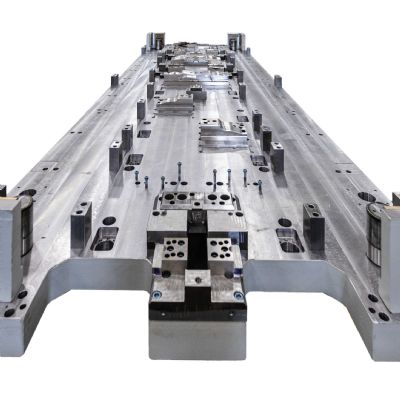

MaterialsTooling Up for AHSS: Know the Material, Mind the Simulation

Lou Kren Tuesday, April 1, 2025

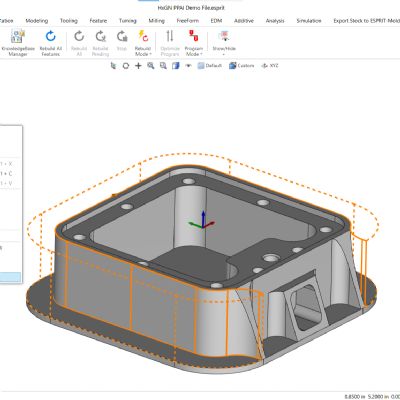

Software

SoftwareAI-Powered Automation Promises to Slash Machine-Tool Program...

Wednesday, March 5, 2025