Camera Gauge Monitors Auto-Adjusting Spring Manufacturing

February 1, 2014Comments

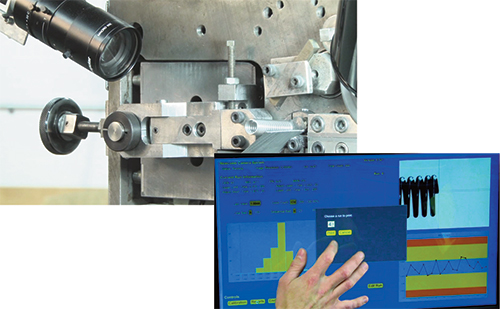

Newcomb Spring Corp., Decatur, GA, has developed a camera gauge setup that provides precise, image-based length measurements, with data recording and reportable order details. The system measures compression springs during manufacture, capturing and saving a digital image of each part and recording part dimensions. If part measurements approach maximum tolerance levels, software automatically triggers an adjustment in connected wire-coiling machinery, causing the equipment to recalibrate and comply more closely to nominal specifications. Upon order completion, a report and digital record is available for download. With its high-speed, automated operations, the Newcomb Camera System allows the company to efficiently produce precise compression springs and to provide a complete production report, accounting for all parts manufactured.

Newcomb Spring Corp., Decatur, GA, has developed a camera gauge setup that provides precise, image-based length measurements, with data recording and reportable order details. The system measures compression springs during manufacture, capturing and saving a digital image of each part and recording part dimensions. If part measurements approach maximum tolerance levels, software automatically triggers an adjustment in connected wire-coiling machinery, causing the equipment to recalibrate and comply more closely to nominal specifications. Upon order completion, a report and digital record is available for download. With its high-speed, automated operations, the Newcomb Camera System allows the company to efficiently produce precise compression springs and to provide a complete production report, accounting for all parts manufactured.

Says Don Jacobson, Newcomb Spring chairman: “The system lets us compare parts to on-screen data, confirming that the springs are being manufactured within allowable tolerances. And, it allows us to export a full report of the order details. Customers have asked for more accountability, as their designs and part applications become more complex. We can download a report showing every spring formed, and part-length data for each part.”

With a high-resolution 10X macro camera lens, the system compares dimensional image data to a preset tolerance range and rejects parts falling outside of that range, sorting them into holding bins. At the end of the run, Newcomb operators count rejected parts and compare the count to the system’s report, confirming all data is correct.

Newcomb Spring Corp.: 770/981-1770; www.newcombspring.com

See also: Newcomb Spring of Atlanta, Inc.

Technologies: Sensing/Electronics/IOT

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Quality Control

Quality ControlIndustry 4.0 Applications in the Sheet Metal Forming Industr...

Eren Billur March 27, 2025