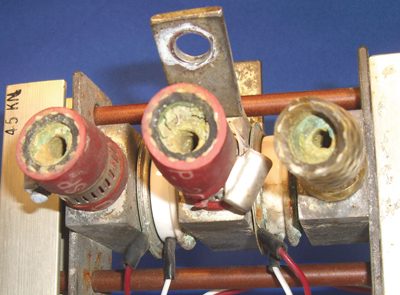

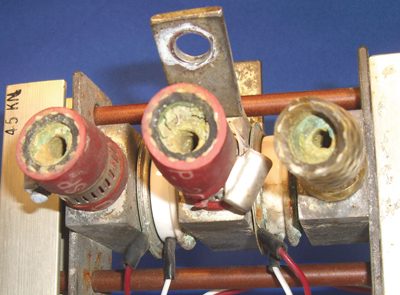

Loose connections are common and eventually will lead to arcing between the mating copper surfaces, which causes pitting, reduces the contact area and limits welding current. Remachining these surfaces may be required to restore the welding machine to full power. (Fig. 1)

We recommend breaking down a machine’s secondary electrical connections at least once per year for cleaning and polishing. Some users even silver plate the connections to improve conductivity.

If replaced during maintenance of a welder’s secondary connections, be sure that bolts are nonmagnetic, such as brass or stainless steel.

May the Force be with You

|

| Fig. 2—Accumulation of contaminants within water passages can cause a welding machine to overheat. |

Because resistance welding is a forging process similar to an old-time blacksmith hammering red-hot metal together until it fuses at the joint, proper operation of the welder’s force-delivery system is critical to weld quality.

To form a strong weld nugget at the interface of the welded part, one or both of the opposing electrodes must move minutely at the instant the metal achieves a molten state. This forging action, called fast follow-up, must be present whether the force is applied with a pneumatic cylinder, air-over-oil cylinder or electric servo.

To minimize moisture in the air supply, a common problem seen with air-operated resistance welders, compressors should be equipped with an air dryer, and each machine should have its own air filter and regulator.

If not permanently lubricated, make sure that the cylinder’s lubricator (oiler) is set properly, with approximately one drop of lightweight oil per 20 machine strokes. Most lubricators are set too high, resulting in the machine’s air-exhaust mufflers, if installed, becoming clogged with oil. In addition to making a mess, this restricts air from exiting the cylinder and can reduce weld quality due to inadequate forging force.

Yearly preventive maintenance of an air-operated resistance welder should include a look inside of the air cylinder. If moisture is in the air supply and if the machine sits idle, cylinder walls and shafts may become pitted and need polishing or replacement.

Keep Your Cool

Water-cooled machines require at least 1.5 gal./min. of water per circuit when the welder runs production.

|

| Fig. 3—Condensation can cause problems inside of welder controls. |

|

| Fig. 4—Rebuilds transform decades-old quality resistance welders into machines that look and work like new. Shown here: before and after images of a completely stripped and remanufactured machine, and a new welder control with programmable functions. |

Heavy-duty single-phase AC welder transformers, the industry standard for decades, tolerated overheating due to lower water flow, but that is not the case with newer-technology three-phase, mid-frequency direct-current (MFDC) power supplies in wide use today.

MFDC units will not withstand abuse and output diodes will short out quickly if operated without proper cooling. MFDC power supplies need at least 2 gal./min. and possibly more if noted on the data tag. Water quality also is important, with the American Welding Society’s C1 document providing good information on cooling-water chemistry.

Long-term machine performance relies on proper maintenance of the water-cooling system. If connected to city or well water, we often see “gunk” accumulate inside of the hoses and other water passages, which are often small-diameter copper tubes. Contaminants such as mud, slime, algae and scale can partially or totally block the flow of cooling water, causing the welder to overheat. (Fig. 2)

Various commercially available cleaning solutions can help remove deposits from a welder’s internal water-cooling lines. Choose a cleaning system that does not attack copper and brass and be sure to install a water filter to catch what is flushed out.

Avoid the problem altogether by connecting the welder to a self-contained recirculating refrigeration-type water chiller that can provide coolant at a consistent temperature and flow rate. However, a chiller also can cause problems if it is set to operate below the prevailing dew-point temperature, which creates condensation. In addition to causing the welder’s electrodes and electrode holders to sweat and drip on the floor at the operator’s feet, the machine’s water-cooled transformer could short out when internal insulation breaks down due to water saturation.

Another common victim of condensation: the water-cooled silicon-controlled rectifier (SCR) contactor inside of the welder’s control cabinet (Fig. 3). A chiller that includes an optional dew-point-compensation feature helps avoid condensation by automatically adjusting water temperature based on prevailing conditions.

Control Your Future

If the control on your resistance welder is more than 10 years old, consider an upgrade. Like all electronics, welder controls become obsolete quickly and manufacturers no longer support many models. Therefore, it pays to be proactive and avoid a crisis. Even if your older controls work well, new models, with various monitoring and feedback features for enhanced weld quality and worker safety, deserve consideration.

Your machine may be an ideal candidate for a makeover or upgrade. Rebuilds transform decades-old quality resistance welders into machines that look and work like new, with some retrofitted with new MFDC power supplies and controls (Fig. 4).

It comes down to this: Show your resistance-welding machines some respect via preventive maintenance, makeovers and upgrades and you will avoid production delays. Your efforts will be worth the time and money. MF

Industry-Related Terms: Brass,

Case,

Conductivity,

Electrodes,

Form,

Lines,

Nugget,

Oxidation,

Plate,

Polishing,

Scale,

Stainless SteelView Glossary of Metalforming Terms Technologies: Welding and Joining