Hardenability and Its Effect on Weld-Quality Evaluation

Again because of their high alloy content, AHSS grades tend to be much more hardenable (likely to form martensite) relative to conventional steels. To assess a steel’s hardenability, metallurgists refer to carbon equivalence (CE)—a high CE indicates a high probability for martensite formation.

|

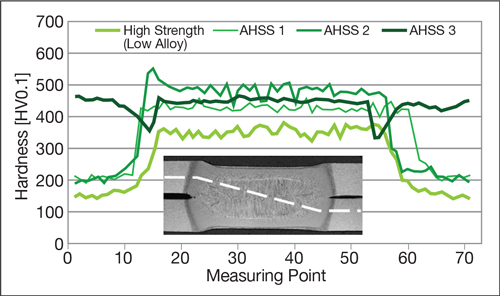

| Fig. 3—Microhardness traverses of spot welds reveal much higher hardness values for AHSS compared to conventional high-strength low-alloy steels. Source: WorldAutoSteel |

For example, the WorldAutoSteel organization used a CE formula called the Yurioka Equation to determine the CEs of some TRIP and DP steels (in the range of 1000-MPa tensile strength). These steels approached CEs of 0.6 –extremely high when compared to that for high-strength low-alloy steels (Fig. 3).

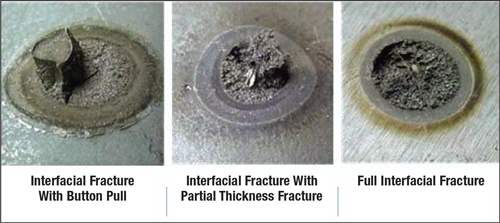

While automakers have successfully resistance welded AHSS grades for the last few years, the high strength and hardness often will affect spot-weld failure modes during weld-quality evaluations using the typical peel and chisel testing methods. A well-established industry standard associated with peel testing of conventional steels states that an acceptable peel test “pulls a nugget” or a “full button.” However, with AHSS, full-button pulls are less likely due to the high CEs that likely will produce hard weld nuggets. Compounding this fact, the higher yield strengths of the material will tend to produce greater stresses concentrating at the edge of the nugget during a peel or chisel test.

|

| Fig. 4—Conventional peel and chisel testing of spot welds in AHSS sheet likely will produce interfacial or partial interfacial failure modes, which can occur even when weld strength is acceptable for the intended application. |

Improving AHSS Welds

|

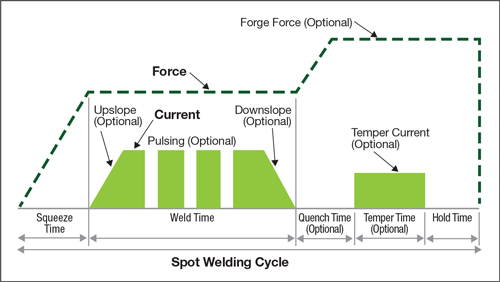

| Fig. 5—To improve nugget failure modes for AHSS, by softening the martensite, fabricators add a temper cycle at the end of the RSW process. |

Of course, the quench time adds cycle time to each weld, so production requirements mandate that this time be kept as short as possible. In addition, there are other approaches to reduce the cooling rate, including current pulsing and current sloping, and use of longer weld times and shorter hold times. MF

View Glossary of Metalforming Terms

Technologies: Welding and Joining