“The relationship between the structural dynamics, cutting force, chatter and part accuracy will be described,” Schmitz says. “I will show how chatter-free milling parameters can be chosen at the process-planning stage to help provide first-part-correct performance.”

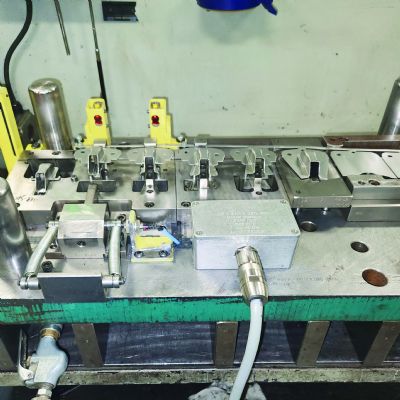

Next up: a talk on additive manufacturing (AM) applications for metal stamping processes and dies, by a pair of researchers working on the R&D staff at Oak Ridge National Laboratory: Mark Noakes and Andrej Nycz. Noakes and Andrej will present their findings regarding the use of AM for die production, specifically the ability to reduce the required machining process by as much as 50 percent. AM also finds use, they say, for prototyping and for fabrication of quick-run parts, “capabilities that automakers need,” Noakes says, “during vehicle development, which allows for shorter lead times and quicker reaction to changes.

“Producing metal stamping dies using additive processes reduces lead times when manufacturing tooling,” Noakes adds. “It also makes North American tool and die makers more competitive in the market. Reducing raw material needed to produce a stamping die by adding metal to near net shape rather than removing material to net shape offers advantages in material and cost savings as well.”

Welding Tool Steel Effectively

Wrapping up day one is a talk by Berth Nilsson, from Uddeholm AB, on the welding equipment and techniques required to successfully weld tool steel. Nilsson will explain to attendees how to choose the correct filler material, and the important parameters that require close attention during the welding process. He’ll also discuss what happens if recommended welding procedures are not closely followed, and the resulting effect on tool life.

Breakout Tracks Highlight Day Two

The second day of the conference kicks off with a Tool and Die Industry Update and Forecast, from renowned industry expert and speaker Laurie Harbour, president of Harbour Results.

“Manufacturing is in the midst of a marketplace evolution,” Harbour says. “From the growth of automated and intelligent technology to new consumer demands, the industry faces many challenges that will require a change in the way suppliers do business.”

Harbour will provide insights collected through the Harbour IQ Pulse Study, looking at performance across different manufacturing sectors. She also will show data proving, on average, that most shops are not prepared for the changing landscape of manufacturing. Harbour then will provide best practices for delivering future success, specifically in the areas of talent, sales and technology.

A presentation on the history of aluminum auto-body sheet metal follows, provided by Laurent Chappuis, president of Light Metals Consultants, LLC. Then, attendees will select among concurrent track sessions addressing various technology topics:

- “Trog-Die” (transfer + progressive) Transfer Systems

- Effect of Edge Condition on an In-Plane Expanding Hole of Aluminum Sheet

- Transfer Die Simulation and Optimization

- Advances and Applications in Friction Stir Welding

Last but not least, stick around to hear a rousing, crowd-pleasing presentation by drummer, motivational speaker and trainer Adam Argullin, titled Mistaken Identity—Are You Your Job? Work-life balance is the discussion topic, focused on the stress placed on ourselves as we become our jobs.

“I’ll discuss healthy techniques, as well as unhealthy habits,” Argullin says, “commonly used to reduce stress, with the ultimate goal of achieving a happy work/life balance.”

To learn more and register to attend, please visit www.pma.org/mstd-conference. MF

View Glossary of Metalforming Terms

Technologies: Management, Materials, Pressroom Automation

The 2020 edition of the Metal Stamping and Tool & Die Conference, presented by PMA in association with MetalForming magazine, once again features industry-leading keynote presentations, educational breakout sessions for stamping and tool and die technology, tabletop exhibits and a networking reception for more than 200 attendees and sponsors. It all happens January 28-29 in Nashville, TN, and features an agenda designed to cover trends affecting the metal stamping and tool and die industries.

The 2020 edition of the Metal Stamping and Tool & Die Conference, presented by PMA in association with MetalForming magazine, once again features industry-leading keynote presentations, educational breakout sessions for stamping and tool and die technology, tabletop exhibits and a networking reception for more than 200 attendees and sponsors. It all happens January 28-29 in Nashville, TN, and features an agenda designed to cover trends affecting the metal stamping and tool and die industries.