Excessive cutting clearances may result in cracking problems. Cracking results spontaneously when the process stresses exceed the tensile strength of the tooling material. Punch cracking is a greater concern with AHSS materials due to their very high tensile strengths. The tensile strength of some AHSS materials can approach that of the tool steels working on them.

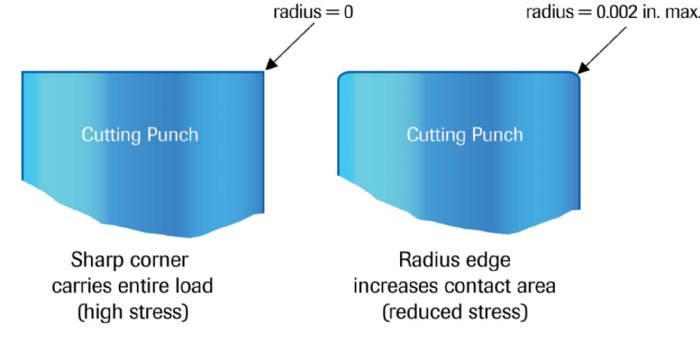

Besides increasing cutting clearances, another method to reduce edge chipping: Add a very small radius to the punch edge (Fig. 1). Accomplish this with a single light pass over the cutting edge using a hand-held India oilstone. The result: a 0.001 to 0.002-in. radius that helps to reduce edge stress.

Besides increasing cutting clearances, another method to reduce edge chipping: Add a very small radius to the punch edge (Fig. 1). Accomplish this with a single light pass over the cutting edge using a hand-held India oilstone. The result: a 0.001 to 0.002-in. radius that helps to reduce edge stress.

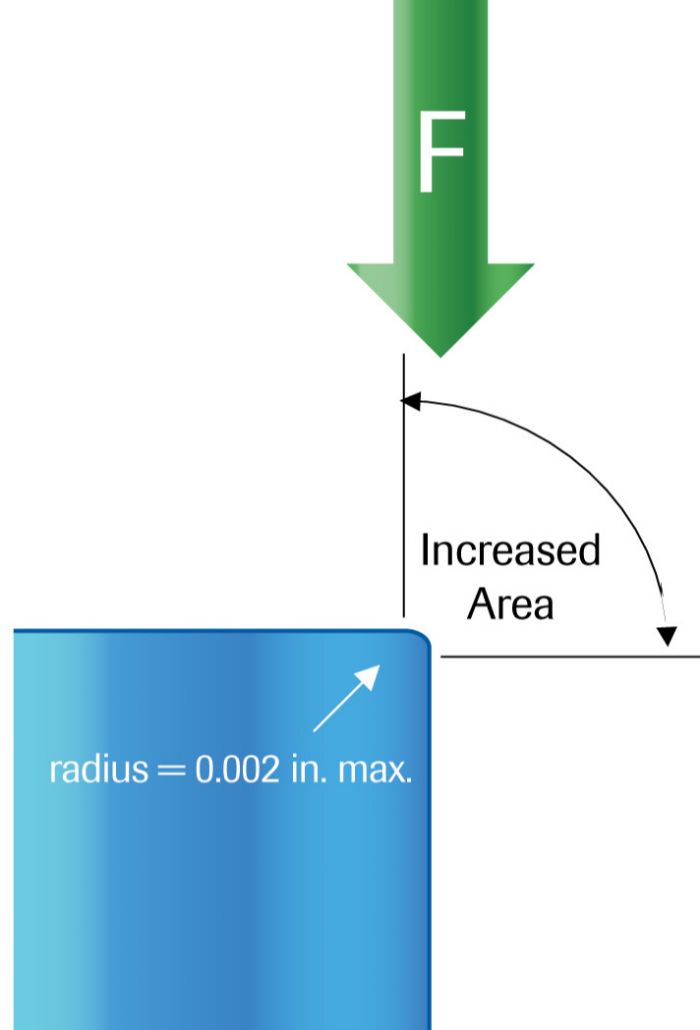

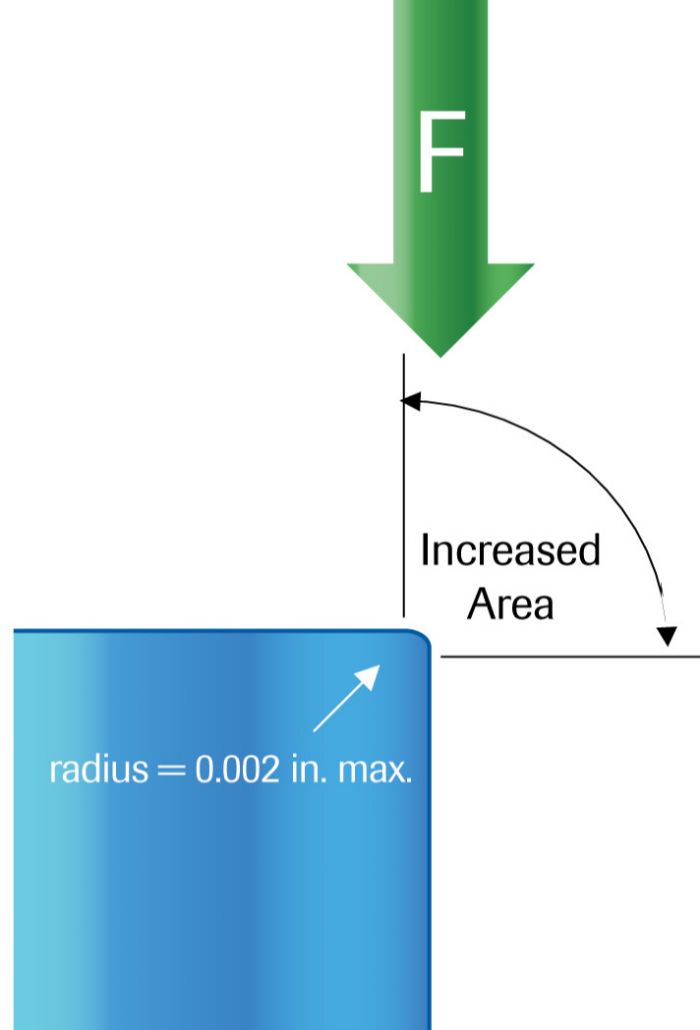

Stress is a measure of an external force acting over the cross-sectional area of an object (Fig. 2). Generally, the cutting force (F) is similar with or without a small radius, but the additional surface area of a small radius reduces edge stress.

Two Types of Wear

Tool wear can be characterized as abrasive or adhesive.

Abrasive wear occurs when the tool material wears away, typically by friction. Reduce abrasive wear by increasing the tooling steel’s hardness, but note that this often reduces its toughness and resistance to adhesive wear.

Adhesive wear (galling) results from microscopic welding at localized contact points between the tool and sheet metal surfaces. Tool extraction shears these microwelds. Shearing occurring on the tool surface removes small fragments, leading to a gradual loss of material.

Reduce adhesive wear by increasing tool-steel toughness—dropping the Rockwell hardness a couple of points—or by reducing the friction between the tooling material. As increasing and decreasing Rockwell hardness entails a balancing act between toughness, abrasive wear and chipping, also consider the proper selection and use of lubricants, tool steel and tooling surface treatments.

Thick and high-tensile-strength materials in blanking operations can subject tool steels to the highest demands of any application. These demands can cause premature wear, chipping, galling and plastic deformation. Strive to achieve the best overall punch performance through a combined balance of tool-steel toughness and wear resistance.

Tool-Steel Selection

The most common tooling material for cold-working dies, D2 steel, can exhibit premature chipping and/or wear when used in applications with higher-strength materials. This makes tooling hardness a prime concern. Hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. In general, tooling hardness usually falls in the range of 58-62 HRC.

For additional chipping resistance and wear resistance, powder metallurgy (PM) tool steels may offer a solution. PM tool steels feature a unique microstructure characteristic: small metal carbide particles uniformly dispersed in the steel matrix. Though more costly, PM tool-steel materials often are more economical due to their low wear rate, and also are good substrates for surface coatings.

Tool steels are only as good as the heat treatment they receive. Unlike machining tools (drills, end mills, etc.), the nature of the stamping process places a high demand on compressive strength and toughness. As controlling these properties directly impacts the performance of the tool steel in service, consider the following when heat treating:

- Segregation by size and material type because each grade has a specific heat-treatment process

- The use of fixturing to ensure even support and uniform exposure to heating and cooling cycles

- Preheat temperature, number of steps and soaking time

- Hardening temperature and soaking time

- Quenching (cooling) rate

- Quenching medium (air, oil, inert gas)

- Tempering temperature, time and number.

Most tool steels feature a generous range of acceptable tempering temperatures. In general, use the highest tempering temperature that will provide the desired hardness. When selecting a tool steel, choose one that best meets the toughness requirements of the job, then improve wear resistance with surface coatings. MF

Industry-Related Terms: Abrasive,

Blanking,

Die,

Edge,

Forming,

Plastic Deformation,

Quenching,

Rockwell Hardness,

Shearing,

Stripping,

Surface,

Tempering,

Tensile StrengthView Glossary of Metalforming Terms Technologies: Tooling

In general, the beneficial properties of higher-strength sheet materials used in automotive applications—high yield strength, high tensile strength and high ductility—also contribute to degraded tool life and promote premature failures.

In general, the beneficial properties of higher-strength sheet materials used in automotive applications—high yield strength, high tensile strength and high ductility—also contribute to degraded tool life and promote premature failures.

Besides increasing cutting clearances, another method to reduce edge chipping: Add a very small radius to the punch edge (Fig. 1). Accomplish this with a single light pass over the cutting edge using a hand-held India oilstone. The result: a 0.001 to 0.002-in. radius that helps to reduce edge stress.

Besides increasing cutting clearances, another method to reduce edge chipping: Add a very small radius to the punch edge (Fig. 1). Accomplish this with a single light pass over the cutting edge using a hand-held India oilstone. The result: a 0.001 to 0.002-in. radius that helps to reduce edge stress.