Setting Small Dies in Large Presses—What Every Press Technician Should Know

November 22, 2024Comments

Mechanical power presses are designed and manufactured to operate within capacity limits established by the press manufacturer. Capacity limits dictate which dies can run safely in the press, and generally include press tonnage and energy, stroke length, shut height, bed size, off-center-loading limits, and stroking speed. Safe die-setting practices require that press technicians understand how capacity limits change when small dies are set in large presses.

Press Capacity

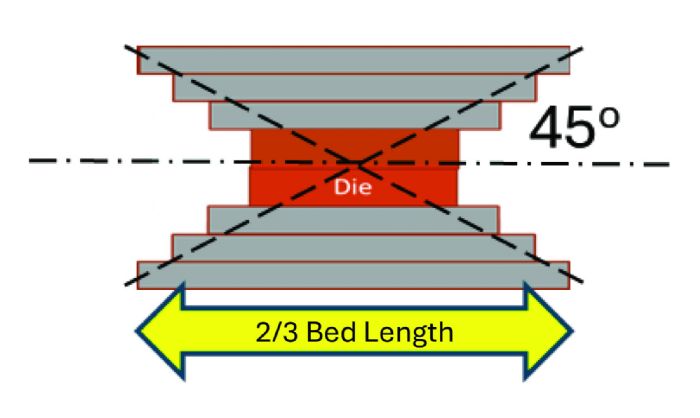

The tonnage rating of a press represents the maximum load (in tons) that a press can withstand under normal operating conditions without causing damage to its structure or drivetrain. The capacity rating of most presses assumes that the die length spans across at least two-thirds of the press slide.

The tonnage rating of a press represents the maximum load (in tons) that a press can withstand under normal operating conditions without causing damage to its structure or drivetrain. The capacity rating of most presses assumes that the die length spans across at least two-thirds of the press slide.

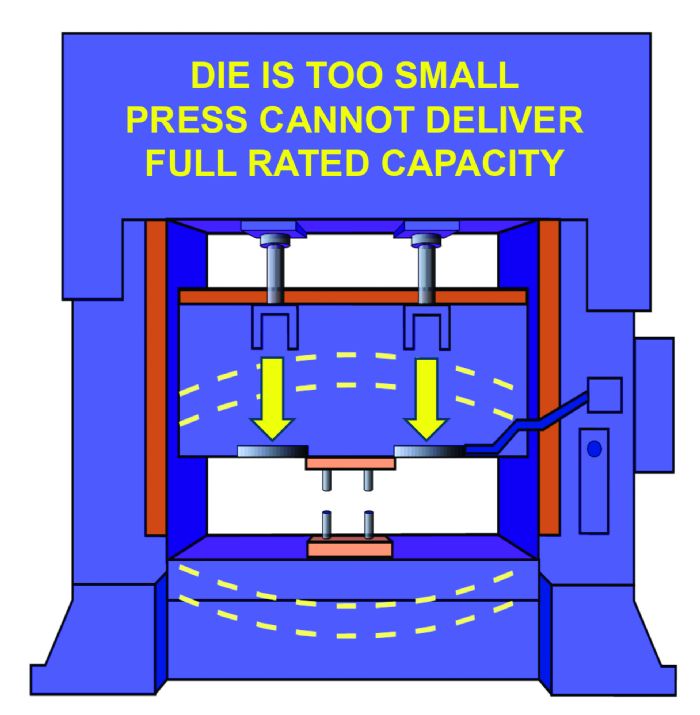

When the die covers less than two-thirds of the bed length, the maximum allowable tonnage is reduced to prevent damage to the slide caused by concentrated loads applied between the pitman connections (Fig. 1).

Reduced-Capacity Example

Assume that one of your presses must be removed from production for service or maintenance. Temporarily assign dies running in that press to other presses until servicing activities are complete.

One die, 30 in. long, requires 285 tons to produce an acceptable part. Open capacity exists in a 600-ton press with a 120-in.-long bed. Can the die run in this press?

On the surface, it appears that 285 tons falls within the capacity of a 600-ton press, thus the die should be able to run in this press (not ‘can’ because in reality it can’t, which is the purpose of the example). Confirm by checking the press manufacturer’s technical manual. However, oftentimes the manual is inaccessible or has been misplaced. How can the press technician verify that the die can be set in the press without exceeding its rated capacity?

The press technician has two choices: Ask to have the die reassigned to a different press, or redistribute the die load across a longer portion of the press bed.

The press technician has two choices: Ask to have the die reassigned to a different press, or redistribute the die load across a longer portion of the press bed.