Machining Moves Made to Quicken Speed to Market

March 1, 2011Comments

This isn’t a car magazine, so I don’t get to test-drive the flashy new models that lit up the stage at the Detroit auto show—models like the recently introduced Camaro convertible.

My Camaro-manufacturing journey took me to a metal stamper known primarily for providing fineblanked throttle plates, lock hardware and similar parts which, virtually overnight, morphed into becoming the sole manufacturer of completely assembled hardware systems for the convertible top on the new Camaro.

“As the Tier Two supplier to Magna for the convertible-top’s steel substructure, we’re busy running 28 new dies and assembling 41 parts in all, including bushing insertion, riveting, welding and tapping,” says Principal Manufacturing toolroom manager John Brazzale. I managed to hit the plant’s production floor (in Broadview, IL) during launch week for the Camaro convertible project, so it’s newly outfitted assembly room, where all of the stampings, fasteners et al come together, was teeming with activity. What I missed, of course, was the flurry of toolroom activity over the last several months that brought the company to this point.

Toolroom Runs Flat Out to Make Fixtures, Gauges

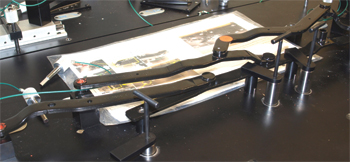

“Our toolroom designed and built all of the assembly fixturing for riveting and welding,” says Brazzale, “a huge project that included gauging and restraining fixtures for our coordinate-measuring machines. Also on the books for this project were design and build of four new fineblanking dies (the rest of the stamped parts are made on conventional progressive tooling that Principal outsourced to other die shops). Our toolroom load more than doubled.”

Long

before the Camaro convertible hit the streets in February 2011, it

created quite a stir on the auto-show circuit. Among its numerous

selling points: refinement of the car’s top, which had designers

seeking a solution to the ever-present rib lines that have plagued

every convertible-top designer for decades…until now. Thanks in part to

the work of Principal Mfg., the top, wrote one car reviewer, has a

“smooth, taut appearance that

retains the vehicle’s sleek roofline.”

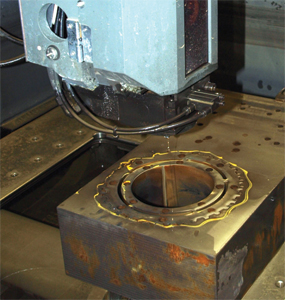

A Fadal vertical-machining center makes quick work machining a die block in the Principal Mfg. toolroom.

The Camaro project now has the pressroom and assembly room at Principal Mfg. turning out 1100 complete units/week—by anyone’s calculations, that’s a lot of stampings and assembly time. Success on a project of this scope only came thanks to the company’s continuous improvements made in its toolroom over recent years—to its die-build procedures, as well as the addition of new CNC wire-EDM machines.

“We invested in new wire-EDM technology (a pair of Mitsubishi FA-20S machines) to increase capacity,” shares Brazzale. Comparing the new technology to old, he says that “we achieve the same surface finish on our die blocks and other machined components, but we get there 15 percent faster than we used to. For example, cutting a die block that once required five passes now takes only three. Our throughput has increased greatly, and hence so has our speed to market with new projects.”