Dampening Reduces Wear on Tooling and Pneumatic Press

May 1, 2009Comments Airam Press Co. Ltd., Covington, OH, a pneumatic press manufacturer, has developed a special dampening material for its presses that reportedly will help stampers improve parts production and reduce tool and press wear by nearly 30 percent. The dampening material is available as an option on Airam B-, P- and G-series pneumatic presses, in capacities from 3 to 210 tons.

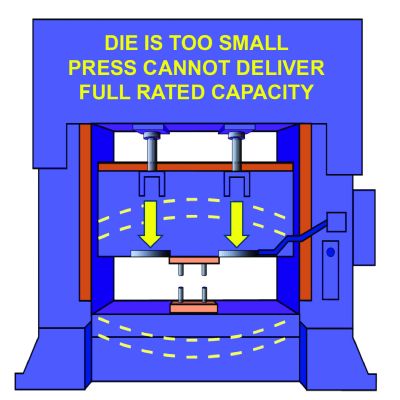

Conventional presses typically contain areas where steel touches steel. The dampening material is placed in these areas, such as the space between the bed and the stand. During a part run, as the bed deflects the dampening material absorbs energy. Because energy no longer is absorbed through steel, the material reduces vibration by as much as 80 percent, according to company officials.

Airam Press Co. Ltd.: 937/473-5672; www.airam.com

See also: Airam Press Co. Ltd.

Technologies: Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Tooling

ToolingWhere to Begin Continuous Improvement of Stamping-Tool Desig...

Thomas Vacca February 27, 2025

Tooling

ToolingSetting Small Dies in Large Presses—What Every Press Technic...

Peter Ulintz November 22, 2024

Tooling

ToolingThe Art of Designing for Manufacturability

Kate Bachman Wednesday, June 11, 2025